Web Guiding System

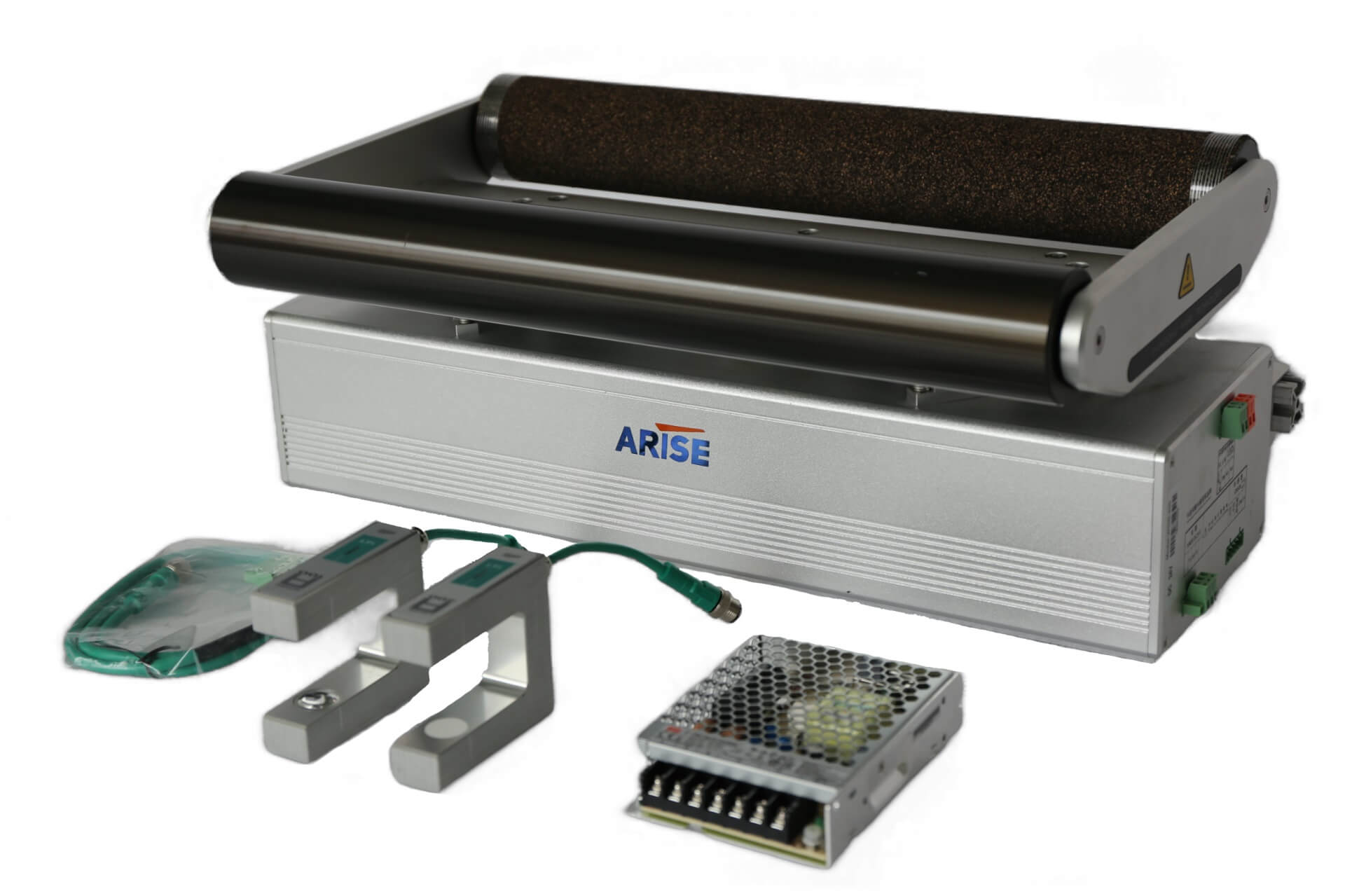

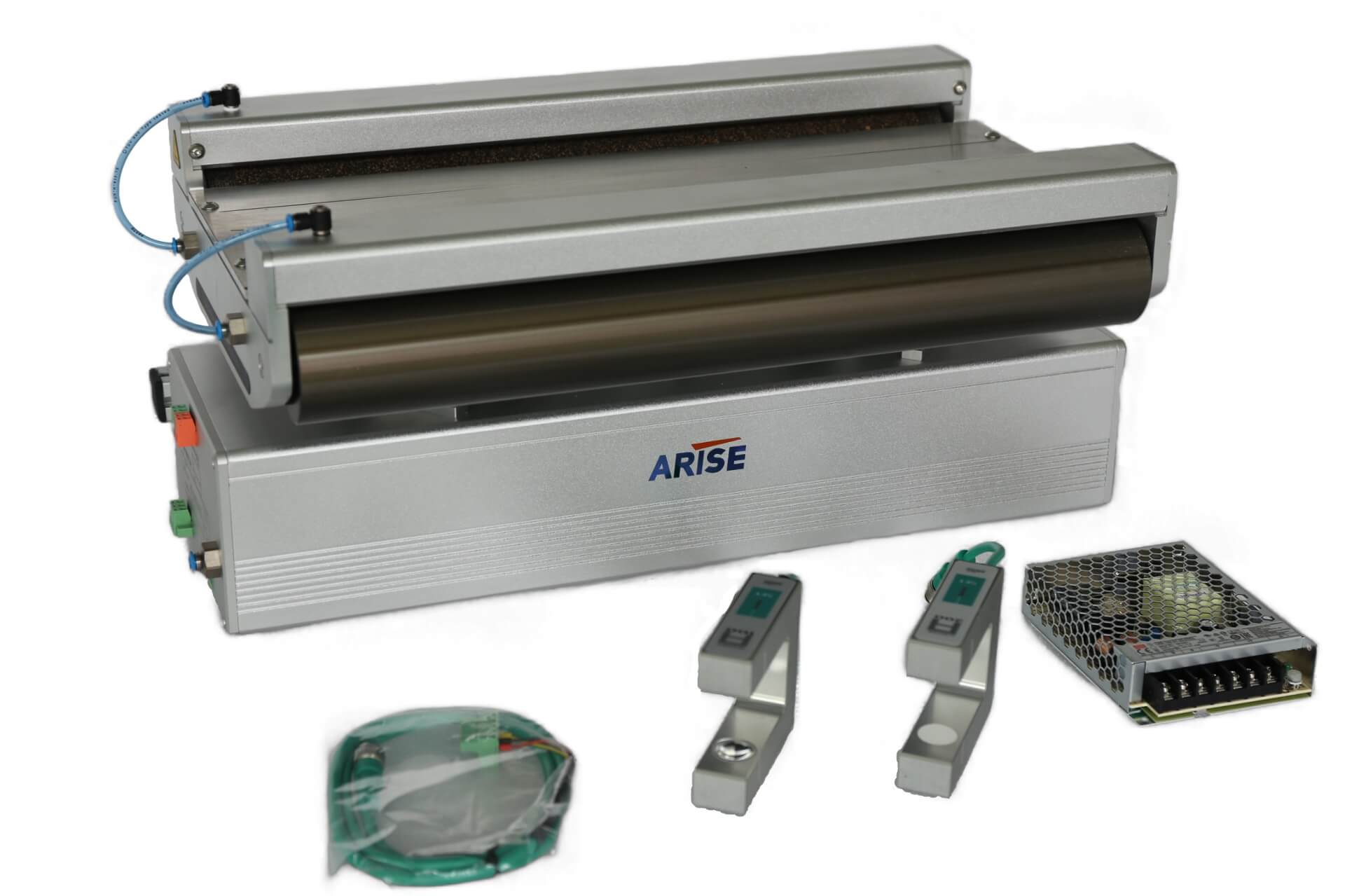

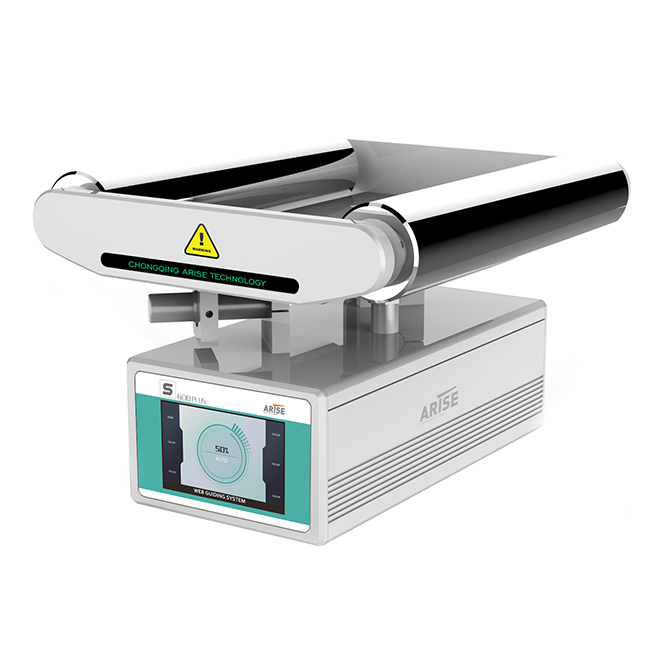

The W500 All-in-one web guiding system is a high-performance solution featuring full touch screen operation. Specifically designed for tracking material edges, lines, and contrast, it excels in automatic web guiding during material movement. Utilizing ultrasonic, infrared, or CCD sensors for signal detection, it calculates material offsets. Based on this data, servo motors and encoder feedback are precisely controlled to correct the material offset. Primarily used in industries such as lithium battery and labeling, it ensures accurate and efficient web guiding processes.

Models: W500

Brand: ARISE

What Is Web Guiding System

The web guiding system effectively manages the positional deviation of coil materials during conveyance in the production line. Offering automatic detection, tracking, and adjustment functionalities, this machine ensures precise alignment of marking lines, paper edges, film, adhesive tape, aluminum foil, and other materials, thus promoting orderly winding and slitting processes.

The Arise web guide system excels in aligning multi-layer materials, with its edge guiding system adept at tracking working material edges or printing lines with high accuracy, differential, and swing capabilities. Notably, it boasts strong anti-interference features suitable for demanding work environments, alongside high reliability and an extended service life.

Introduction Videos of Web Guiding System

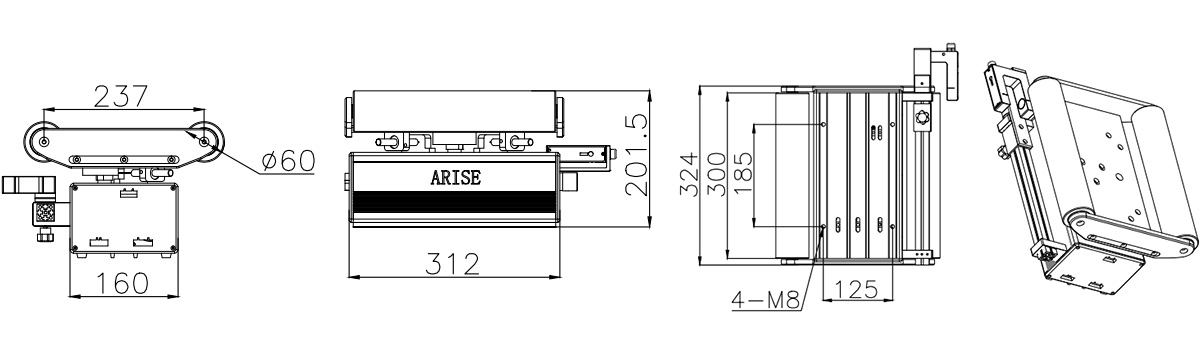

Dimensional Parameter of Web Guiding System

| Model Number Mounting | Hole Size | Roller Length | Body Length | Roller Frame Length |

| 160 | 115mm | 160mm | 189mm | 176mm |

| 200 | 185mm | 200mm | 312mm | 224mm |

| 250 | 185mm | 250mm | 312mm | 274mm |

| 300 | 185mm | 300mm | 312mm | 324mm |

| 350 | 285mm | 350mm | 412mm | 374mm |

| 400 | 285mm | 400mm | 412mm | 424mm |

| 450 | 385mm | 450mm | 512mm | 474mm |

| 500 | 385mm | 500mm | 512mm | 524mm |

| 600 | 485mm | 600mm | 612mm | 624mm |

| 700 | 585mm | 700mm | 712mm | 724mm |

| Precision | <±0.1mm(Depends on material) |

| Error frequency | Maximum 8Hz |

| Rated adjustment stroke LU 160mm/200mm | ±15mm |

| Rated adjustment stroke LU 250mm/300mm | ±20mm |

| Rated adjustment speed on discharge roller | 100mm/s |

| Material tension NB160/200mm | Maximum 200N |

| Material tension NB/250/300/350/400/450mm | Maximum 300N |

| Roller diameter | 40/60/80/100mm |

| Ambient temperature | +5℃ ~+55℃ |

| Relative air humidity | 15~95%(no-condensing) |

| Rated operation voltage | 24VDC |

| Rated range | 20~28VDC(fluctuated) |

| Rated range in use | 100~240V,50/60Hz |

| Current consumption | Maximum 4.5ADC |

| Interface | External manual /automatic |

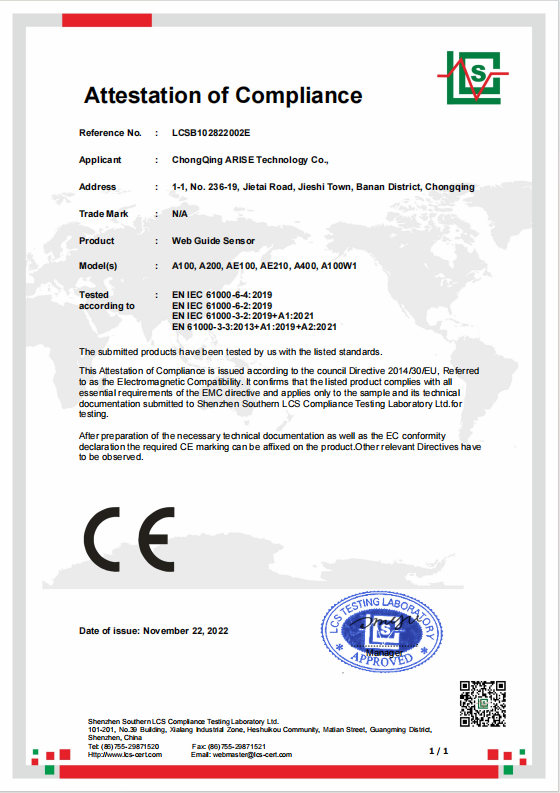

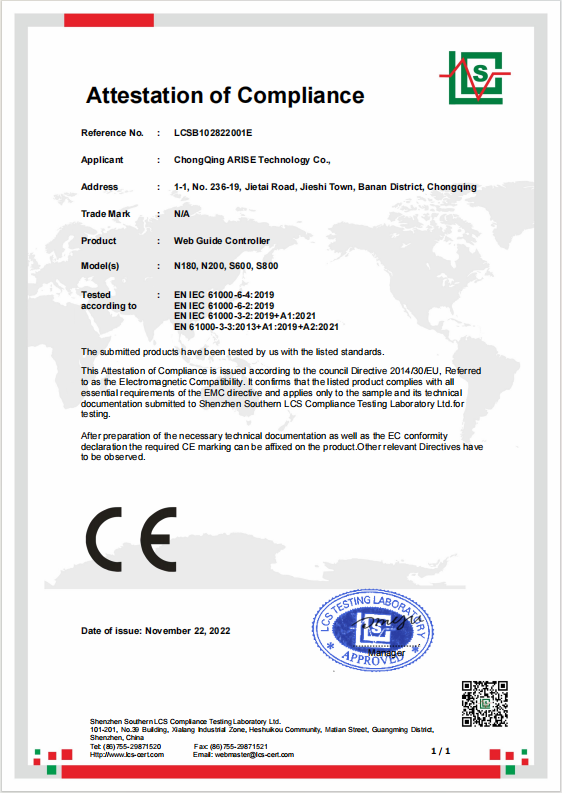

| Certification | Meet the CE standard |

| Protection grade | IP54 |

Features of Arise Web Guiding System

- Single-piece design: securely sealed and compact

- Brushless servo motor drive ensures maintenance-free operation.

- Compatible with various sensors including photoelectric, infrared, ultrasonic, and CCD

- Incorporates a variable PI adjustment algorithm for high precision and fast response, minimizing errors

- Equipped with precision ball screws for accurate positioning

- User-friendly interface facilitates fast and effortless operation

- Features an attractive appearance with aluminum alloy finishing and surface sandblasting oxidation

- Offers flexible installation options: can be integrated, separated, or installed at any angle

How Web Guiding System Works

The web guide machine directs the sensor to emit either infrared or ultrasonic waves to monitor the coil’s operation, transmitting the data to the web guiding controller. Upon detecting any positional deviation, the guide controller executes preset commands, prompting the drive system to adjust and correct the web’s position accordingly.

Key Components

The web guide control system consists of four integral components: a controller, a web guide sensor, an electric drive, and a web guide mechanism, operating within a closed-loop control system. The sensor accurately detects the coil’s edge position, measuring the disparity between the actual and desired positions and translating it into a proportional voltage signal. This signal is then transmitted to the controller, where it undergoes amplification and calibration. Subsequently, the controller sends the processed signal to the electric driver, which in turn commands the web guide mechanism to adjust the coil’s position based on the signal’s magnitude, guiding it toward the predetermined set position.

For more professional knowledge, please visit the article page of web edge guiding system

Working Videos of Web Guiding System

Application Videos of Web Guiding System

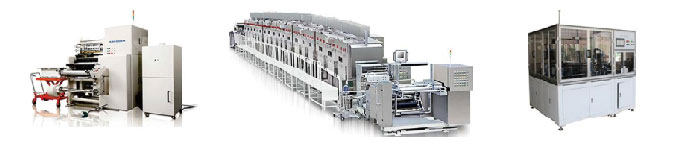

Applications of Web Guiding System

Widely used in many industries

Printing and Flexible Packaging industry

Solvent-free laminating machine, bag making machine, inspection machine, labeling machine, etc.

Battery industry

Lithium voltage film machine, lithium battery slitting machine, lithium battery replacement machine, battery lamination machine, etc.

Film industry

Film blowing machine, replacement machine, film slitting machine, film casting machine, etc.

Tire industry

Fiber steel wire calender, tire building machine, steel cord cutting machine, production line, etc.