Advantages of LS600 Cantilever Tension Sensor

The LS600 series cantilever tension sensor integrates imported full-bridge strain gauges, boasting high precision and temperature compensation, for detection. By employing advanced signal processing and temperature compensation techniques, it ensures remarkable precision, minimal temperature drift, and excellent linearity. Moreover, the sensor effectively shields against static electricity and group pulse interference originating from frequency converters. With its overload limit feature, it safeguards the sensor from damage during overload situations. Additionally, the tension sensors can be configured with various roller lengths such as 200mm, 300mm, 400mm, 500mm, etc. Customization for special models is available upon request.

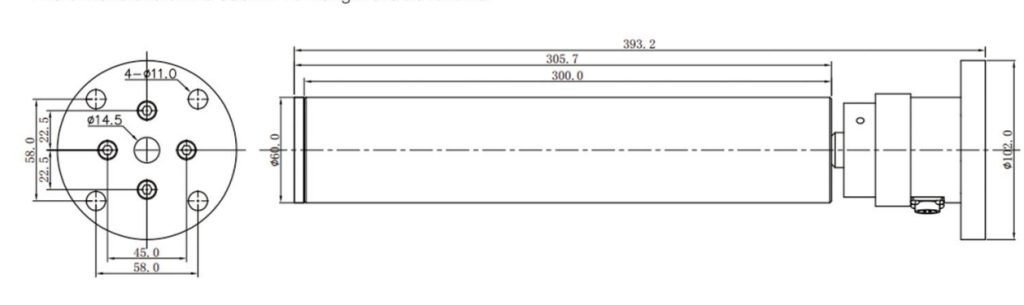

Dimensional Parameters of LS600 Cantilever Tension Sensor

| Tension Measuring | Roller | |||||

| Type | ØD(mm) |

Minimum NB(mm) |

Maximum NB (mm) |

Rated measuring force FN/per roller (N) |

||

| LS600 | 60 | 150 | 300 | 50 | 100 | 200 |

| LS600 | 80 | 200 | 400 | 100 | 200 | 400 |

| LS600 | 100 | 250 | 500 | 100 | 200 | 400 |

Surface of LS600 Roller

| Surface index | Surface |

| 01 | Polishing Ra 3.2 (standard) |

| 02 | Encased in rubber cork |

| 03 |

Fine sandblasted with glass emery, Ra 6.3, hard anodized layer, thickness 30 μm 450 HV |

| 04 |

Hard anodic oxide layer, Ra3.2, thickness 30um 450HV |

The dimensions of the 300mm roll length are as follows:

Sensors can be fitted with different lengths and can be customized if special models are required.