A tension control system is a mechanism designed to regulate and maintain the tension of a material, such as a web or a wire, during various manufacturing processes. This system ensures that the material being processed remains at a consistent tension level, which is crucial for achieving high-quality results in processes like printing, coating, laminating, and converting.

The tension control system typically consists of sensors, controllers, and actuators. Sensors detect the tension of the material, while controllers analyze the data and adjust the actuators accordingly to maintain the desired tension level. Actuators can include brakes, clutches, motors, or pneumatic devices that apply force to the material to either increase or decrease tension as needed.

Web Tension Controller

A web tension controller is a critical device used in industrial manufacturing to maintain consistent tension in a moving web of material, such as paper, plastic, or fabric, throughout the production process. By precisely regulating the tension, this controller ensures that the web remains smooth and properly aligned, preventing issues like wrinkling, stretching, or tearing.

TE200/TE300 Tension Amplifier

A tension amplifier is a specialized device used to enhance the signal from a tension sensor in web handling systems. By amplifying the weak electrical signals generated by the tension sensor, the amplifier provides more accurate and reliable measurements of the material’s tension. This enables precise control and adjustment of tension levels in web-based processes, such as printing or coating, ensuring optimal material handling and reducing defects.

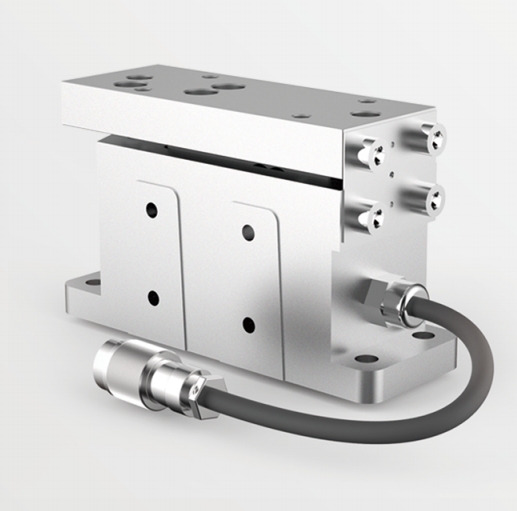

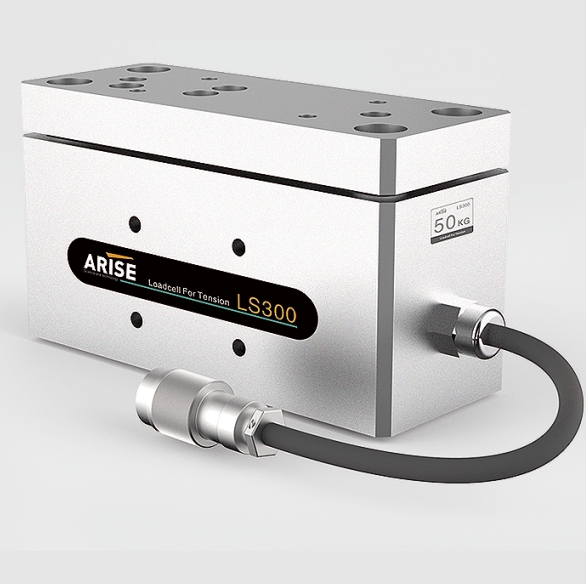

Tension Sensor

Tension sensors are devices used to measure the force or tension of a moving web of material, such as paper, film, or fabric, in industrial processes. It detects the amount of tension in the material and converts this force into an electrical signal, which is then used to monitor and control the web’s tension. Accurate tension measurement is crucial for maintaining material integrity, preventing issues like wrinkles or breaks, and ensuring smooth and efficient production. Tension sensors are integral to systems that require precise tension control for optimal performance and product quality.