Web guiding solutions are systems designed to maintain the correct alignment and positioning of material webs, such as paper, film, or fabric, during the manufacturing process. The web guide system equipment typically comprises sensors or detectors that monitor the position of the web relative to a predetermined path or reference point. This information is transmitted to a guide controller, which then directs actuators to make real-time adjustments to guiding elements such as rollers, guides, or edge sensors.

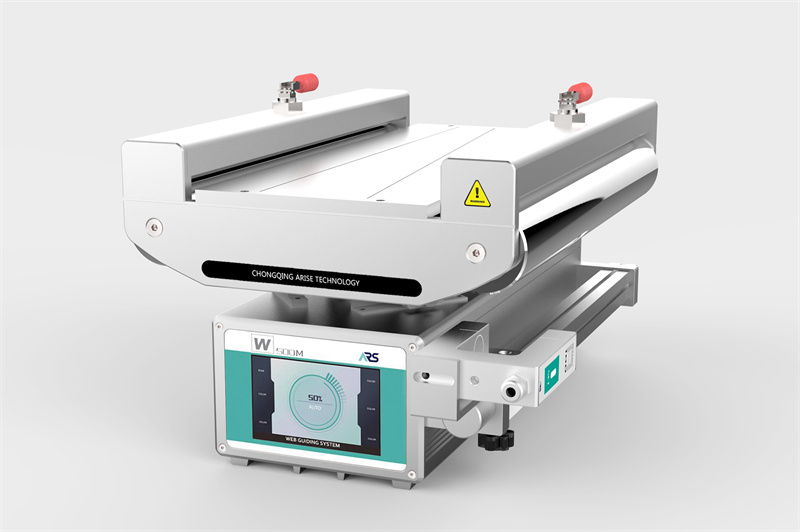

All-in-one Web Guide System

An all-in-one web guide system is an integrated solution designed to ensure precise alignment and handling of web materials, such as paper, films, textiles, and metals, during manufacturing processes. This system combines advanced sensors, actuators, and intelligent control algorithms to detect and correct any deviations in the material’s path in real-time. By maintaining the web’s position within tight tolerances, an all-in-one web guide system enhances product quality, reduces material waste, and improves overall production efficiency, making it an essential tool for modern industrial applications.

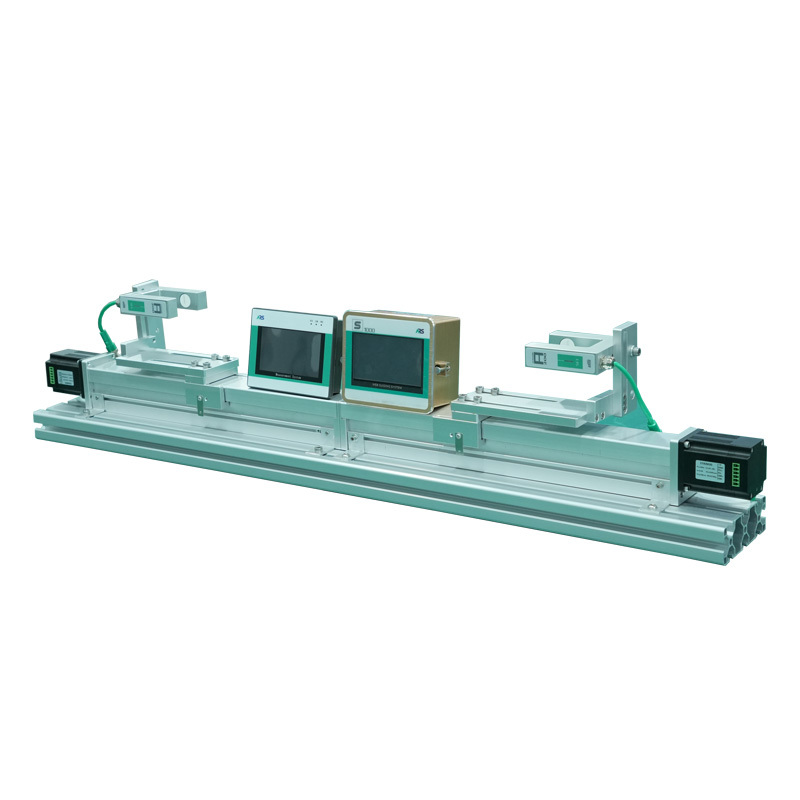

Centering Web Guide System

A centering web guide system is a specialized control solution designed to keep moving web materials, such as films, textiles, or paper, accurately aligned along their central path during processing. Equipped with advanced sensors and actuators, this guiding system detects lateral deviations and makes precise adjustments to reposition the web to its intended centerline. Ideal for applications in printing, packaging, and converting industries, it ensures uniform alignment and improves production efficiency. Its ability to handle diverse web materials and operating conditions makes it an essential tool for high-quality manufacturing processes.

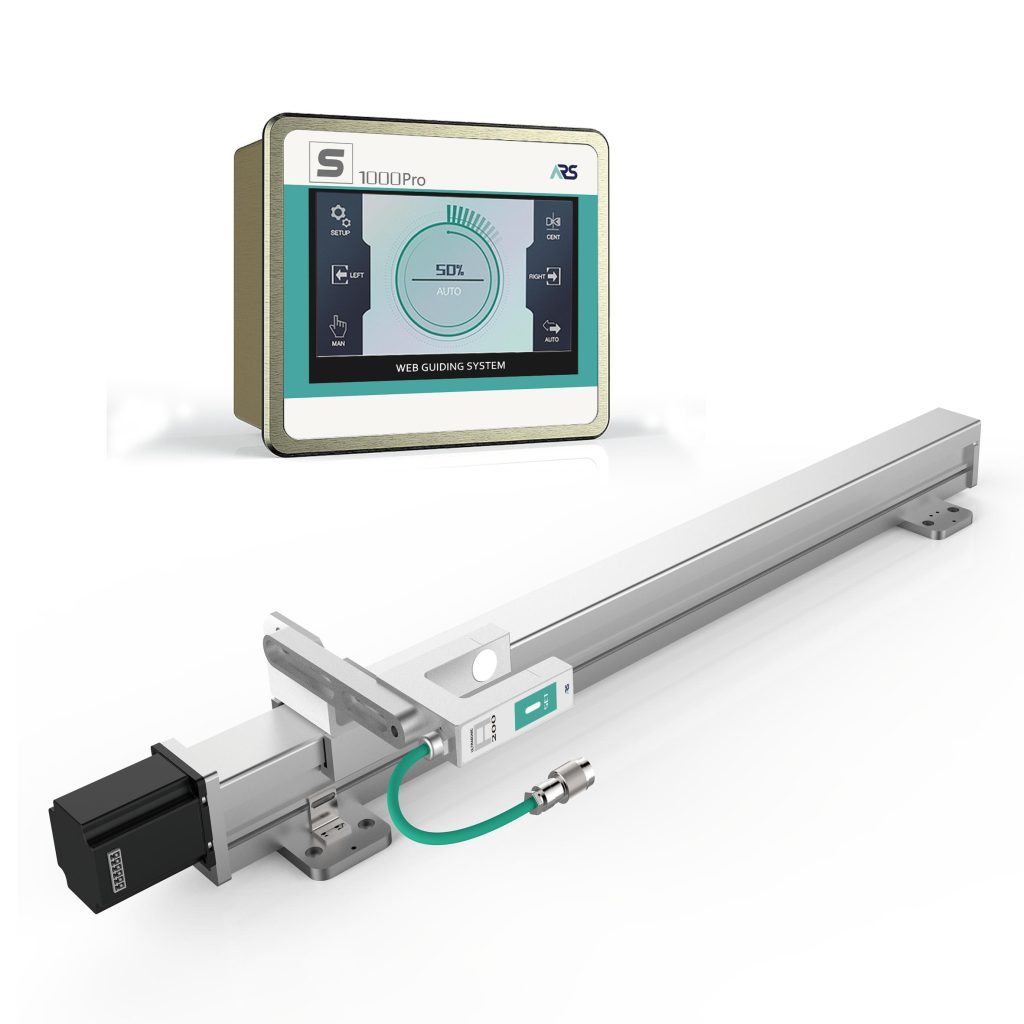

Web Guide Controller

A web guide controller is a crucial component in web guide systems. It is responsible for maintaining the precise alignment of materials, such as paper, films, textiles, and metals, as they move through manufacturing processes. It processes data from sensors that monitor the web’s position and sends commands to actuators to correct any deviations from the intended path.

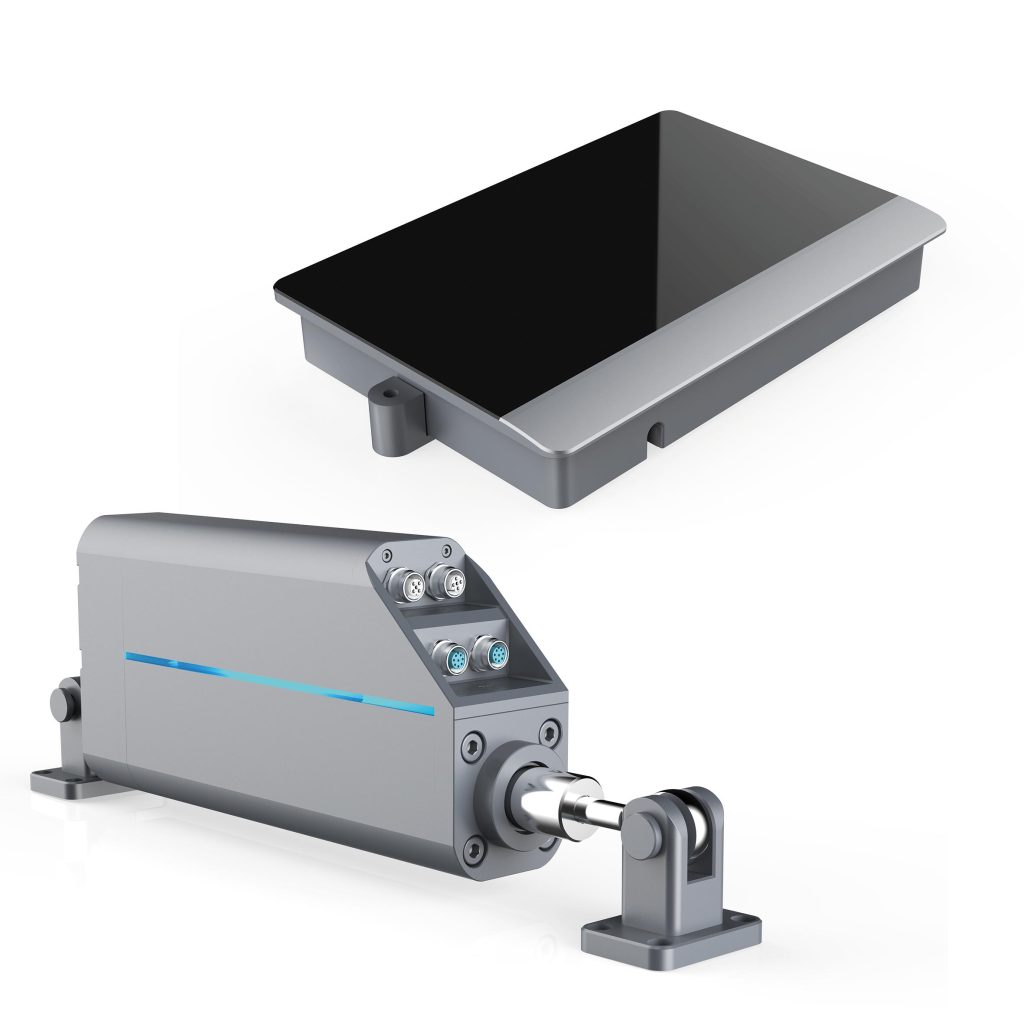

Web Guide Sensor

A web guide sensor is vital in web guiding systems, responsible for accurately detecting the position of moving materials, such as paper, films, textiles, or metals, during industrial production. These sensors monitor the material’s edge, center, or line position and relay this information to the web guide controller. Various sensors, including ultrasonic, infrared, CCD image, etc, are used depending on the specific material and application requirements.

Web Guide Actuator

Web guide actuators are the key elements in web guide control systems that adjusting the position of moving materials, such as paper, films, or textiles, to maintain proper alignment during production. Based on real-time data from web guide sensors, the actuator makes precise corrections to the material’s path, ensuring it stays within predefined tolerances. Modern web guide actuator is designed for high responsiveness and accuracy, often incorporating advanced motor technologies like high-speed, high-torque motors or piezoelectric actuators to achieve optimal performance.

Web Guide Roller Frame

Web guide roller frames are essential for web guide systems, designed to support and guide the moving material, as it travels through a production line. The roller frame provides stability and precise alignment by ensuring the web stays on its intended path, minimizing deviations. Equipped with strategically placed rollers, the frame works in conjunction with sensors and actuators to make real-time adjustments, thereby enhancing material handling, improving product quality, and reducing waste in various industrial applications.