4 Steps to Successfully Install The All-in-one Web Guide System

Web guide technology has developed rapidly in recent years. Thanks to the high-performance automatic web guide control system, the edge position controller ensures that the materials will not deviate from the correct position. The position of the coil is always be tracked during the production process with real-time web guidance without any manual intervention, which ensures and improves the quality and efficiency of the products.

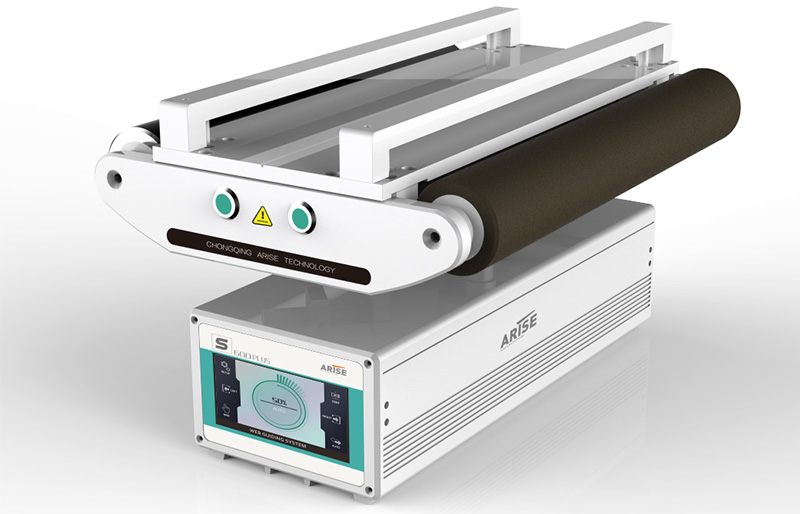

Arise provides a high-precision web guide system with advanced technology and professional certificates, the most competitive price guaranteed.

Characteristics Of The Web Guide System

1. Driven by brushless servo motor, maintenance-free

2. Precision ball screw

3. Large guide stroke

4. The length and span of the guide roller can be customized

5. The mesh material which is the most difficult to detect, also be easily controlled

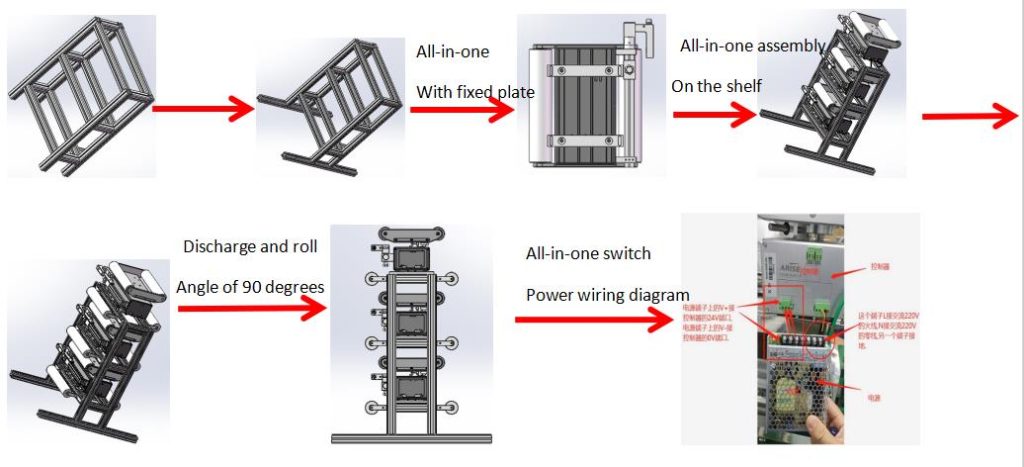

The Installation Steps Of Web Guide System

Mounting

1. Make sure to install the guide correctly according to the direction of the roll paper and the marks on the roller platform. The sensor must always be downstream on one side of the material flow.

2. Fix the guide on the machine by using the supplied bolts

3. Tighten each bolt with a wrench by hand until each bolt is firmly locked. Do not tighten the bolts.

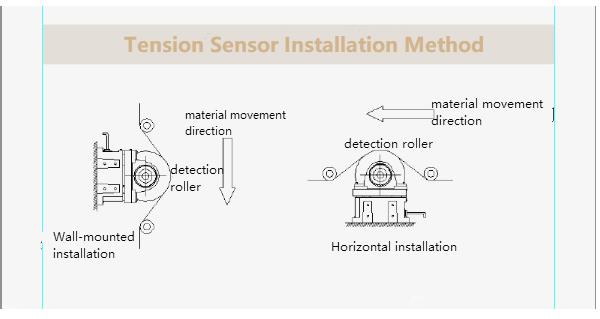

Installing the sensor

- The sensor assembly consists of a sensor head, a sensor connection cable, and two sensor carriages with M3 thumbscrews. All these elements are shipped from the factory.

2. Assemble into a ready-to-install unit.

3. Each sensor carriage will have a locking thumbscrew. Loosen the two thumbscrews to allow the carriage to slide into the sensor guide, which is installed under the roller assembly on the downstream side of the roll paper guide.

4. There is a filter cover (infrared or visible filter cover) on the surface of the sensor. When the sensor assembly slides into the guide rail, make sure that the filter cover faces the roll paper material.

5. After installing the sensor to the sensor rail, install the plastic end cap on the end of the rail. Clip-on plastic end caps are usually equipped with roll paper guides.

6. After installing the sensor, connect the sensor connector at the end of the sensor cable to the sensor port on the connector interface on the other side of the housing assembly.

Pre-wired

In the pre-wiring option, the equipment may be supplied with a 2.5-meter power cord (via compression nut) for customers to connect to a properly grounded 24 VDC power source.

Grounding

For safety and normal operation, a web guiding system is an equipment used by the web and the installed guide plate must be properly grounded. The ground screw on the back connector is to connect the ground wire interface.

When the installation has been finished, you should test the web guide system. Concerning the detailed information, please visit the article on tips to test and operate the web guide system

Professional Web Guide System Manufacturer – Arise

Arise is a professional web guide system manufacturer, located in Chongqing, China and it focuses on the research, development and production of position sensors, web guiding systems, and tension systems including photoelectric, CCD, color sensitivity and ultrasonic. The products are widely used in steel, no-woven fabric, corrugated paper, textile, printing, labeling, plastic film, building materials, cables, rubber, tires, etc. The web guide equipment provided by Arise will ensure that your machine runs normally at full speed. The automatic guide system can ensure continuous, accurate control of various types of materials in various production processes, and limit waste and downtime to a minimum.