100% Inline Inspection in the High-speed Print Industry

In the fast-paced, precision-driven world of high-speed printing, quality control has evolved beyond random sampling and manual inspection. The introduction of the 100% inline inspection systems in the print industry represent a major leap, enabling real-time, full-surface monitoring of every printed items as it moves through the printing press. These systems are essential in ensuring defect-free output, minimizing waste, and meeting the stringent quality expectations of a range of industries such as packaging, labeling, pharmaceuticals, and security printing.

Table of Contents

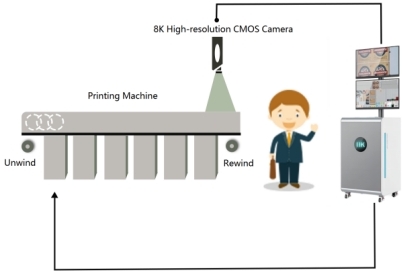

What is 100% Inline Inspection

100% Inline inspection is an ongoing, automatic review of every item on a production line, using high-resolution cameras and sensors and sophisticated algorithmic image processing. Contrary to sampling-based processes which examine every produced item without disrupting production, while identifying even the smallest imperfections in alignment, color or registration, print density, or the content.

Why Need 100% Inline Inspection in the High-Speed Print Industry

Rising Demands for Print Quality and Consistency

In the current competitive print market the expectations of customers are higher than ever. Brands expect top-quality print to safeguard their image however, consumers are less accepting of misprints or flaws in packaging. The use of high-speed printing in labeling, packaging, and commercial printing, increases the likelihood of problems not being noticed. Inline inspection in 100% is essential to ensure that every print is in line with the standard and not relying on samples alone.

Limitations of Traditional Quality Control

Inspection methods based on samples or manual procedures cannot keep pace with the rapid pace of contemporary printing. Random checks can only catch only a small portion of output, which leaves room for printing issues to go unnoticed. In production lines that are high-speed, one unresolved issue could cause thousands of wasted units. 100% inline inspection provides live, complete-coverage monitoring, which can eliminate this undiscovered problem.

Immediate Detection, Immediate Correction

One of the main benefits of 100% inline inspection is the ability to detect defects in real-time. The system constantly compares every printed item to a reference photo or digital proof. If there is a deviation, such as misalignment, color variance or text that is missing, it sends instant notifications to operators or automatically initiates corrective actions. This reduces the amount of waste and stops the recurrence of unnoticed errors.

Ensuring Compliance in Regulated Industries

In fields like food and pharmaceuticals, as well as security printing, accuracy of print isn’t just an issue of security and compliance. A misplaced dosage label or a barcode that’s not readable could result in recalls, legal issues or health risk. Inline inspection 100% is crucial for confirming vital information and ensuring that strict standards are adhered to by regulators.

Maximizing Operational Efficiency

Beyond the control of quality, inline inspection increases the efficiency of operation. By catching issues early, it can reduce the expense of rework as well as the waste of materials. It also decreases the time spent on repairing presses by identifying patterns and trends in the form of defects, which allows for the maintenance of processes in a way that is predictive and allows for adjustments. It also allows for continuous production, without compromising quality.

Data-Driven Traceability and Analysis

Modern inspection systems that are inline don’t just find defects, they keep track of every inspection’s results. This data allows for traceability, quality documents for audits, as well as a deep analysis of issues that are recurring. As time passes, it assists manufacturers to improve processes, lessen variation, and build a quality assurance system.

A Necessity in the Digital Printing Era

As hybrid and digital presses are becoming more commonplace shorter runs and frequent changes to jobs are becoming commonplace. 100% inline inspection system guarantees that every digital print job has excellent quality from the very first machine to the last. In this regard the real-time inspection process becomes an essential element of a modern, flexible printing strategy.

Technologies Behind 100% Inline Inspection for the Printing Industry

100% inline inspection systems use advanced imaging and intelligent software to examine every single printed unit in real time. Behind this powerful capability is an array of technologies that assure accuracy, speed and adaptability across a variety of printing environments.

1. High-Resolution Camera Systems

The heart of the inline inspection system is a digital high–resolution camera. They are strategically placed in the press’s direction to capture frames-by-frame or continuous images of the substrate. They are equipped with line scan or areas scan features and offer microscopic clarity even at very high production speeds. Line scan cameras, particularly they are ideal to print high-speed web pages because they can print wide-screen images one line at one time, with outstanding clarity and sync.

2. Precision Illumination and Lighting Control

Lighting is crucial for accurate imaging. Inline inspection systems employ high-intensity LED lighting – often with spectra or colors that are different to ensure uniform illumination across different kinds of materials and types of prints. Depending on the purpose the diffuse, coaxial as well as strobe light techniques could be used to emphasize the surface’s features, reduce reflections, and increase contrast. The adaptive lighting system adjusts its brightness in real time to adjust to variations in the color of the substrate or texture, which improves the detection of defects across different printing jobs.

3. Real-Time Image Processing and Comparison

Images captured are immediately processed by powerful computing systems. The web inspection vision systems for the printing operations, match each printed image against an electronic master or reference file by using sophisticated algorithms for image analysis. Anything that is not in line with the accepted standard, such as color variance streaks, misregistration or spots or characters that are missing is identified as a defect that could be a cause for concern. The ability to process real-time data permits immediate detection, without affecting the speed of the press making sure that the defects are identified as soon as they show up.

4. Artificial Intelligence and Machine Learning

Inline inspection systems for integrating AI machines and machine learning algorithms in order to increase the accuracy and flexibility. They can tell the difference between minor defects that are critical and acceptable variations, which reduces false alarms as well as fatigue for the operator. Machine learning allows systems to grow in the long run by learning from the past defects patterns and improve their ability to anticipate and avoid recurring problems.

5. Integration with Production Systems

Inline inspection technology is firmly connected to the press as well as the other line of production systems. This integration enables automated responses, like altering alignment of the print or stopping the press or activating the defect marking system and reject systems. In the case of advanced setups the inspection system will connect to finishing machines as well as roll-mapping equipment, making sure that damaged material is identified and removed from down the line.

6. Cloud Connectivity and Data Management

The most recent generation of inspection systems has cloud-based connectivity and central data management. Manufacturers can collect inspection data across multiple lines and locations which allows real-time monitoring historic analysis, and tracking. Web-based dashboards offer visual insights into trends in quality as well as system performance and production irregularities, which aid in constant improvement and compliance with regulatory requirements.

7. Customization for Different Printing Applications

Inline inspection systems can be adaptable to different printing techniques, including flexographic, offset, gravure as well as hybrid presses. Based on the type of application it can be adapted to target specific functions like the verification of variable data, colors monitors, barcode readability. This makes the technology flexible and applicable to everything that includes food and pharmaceutical packaging as well as security printing.

Benefits of 100% Inline Inspection in High-speed Print Industry

| Benefit | Description |

| Real-Time Defect Detection | Instantly detects printing errors when they occur, thus preventing damaged output. |

| Reduced Material Waste | It flags issues or stops them before they occur minimising the need for reprints and waste. |

| Improved Product Quality | Every printed item is guaranteed to meet the exact specifications and quality standards. |

| Faster Problem Resolution | Gives operators immediate feedback for rapid correction of print problems. |

| Regulatory Compliance | Important for industries such as pharma and food where precision is essential. |

| Increased Production Efficiency | Press speeds are maintained without compromising inspection precision. |

| Enhanced Brand Protection | Labels and packaging that are not properly designed which could damage the image of a brand. |

| Traceability and Audit Trails | The logs record inspection data to ensure accountability analysis, as well as continuous improvement. |

| Lower Operational Costs | This reduces scrap, downtime and the costs of manual inspections over time. |

| Customer Satisfaction | Prints consistently high-quality, consistent prints, which reduces complaints and return. |

Challenges and Solutions in 100% Inline Inspection for the Print Industry

| Challenge | Description | Solution |

| High-Speed Image Capture | Capturing sharp images with high speeds of press can cause motion blur. | Make use of high-frame-rate line scanners that have synchronized strobes or LED lighting to reduce blur. |

| Substrate and Print Variation | Different materials, finishes and ink types impact the accuracy of inspection. | Create adaptive lighting systems as well as smart calibrations for every type of substrate. |

| False Positives in Defect Detection | The system can detect small or insignificant imperfections as crucial imperfections. | Integration of AI algorithms that are able to categorize defects according to their severity and decrease false alarms. |

| The Complex Integration with Presses | Retrofitting inspection equipment into existing lines could interfere with the flow of work. | Utilize modular and compact inspection systems that are easy to integrate with different press configurations. |

| Frequent Job Changes and Short Runs | Regular changes to the setup for different print jobs decrease the effectiveness of inspection. | Automate job setting, template matching, and changeover routines that will speed up the process of changing jobs. |

| Color Consistency Issues | Color shifts that are subtle are difficult to discern at high speeds. | Utilize inline color monitoring tools as well as digital color matching tools to ensure uniformity. |

| Data Overload due to Continuous Scanning | The massive amount of data from images can overtake the storage or analysis software. | Make use of real-time edge processing and cloud-based analytics to improve data processing. |

| Operator Training and Usability | The complexity of systems makes it challenging for the operators to effectively manage. | Offer user-friendly interfaces as well as comprehensive instruction for operators to improve their usability. |

| High Initial Investment | The cost of software, hardware and integration could be significant for small – to mid-sized printers. | Maximize the long-term ROI via reduced waste, higher quality, and less complaints. |

| Long-Term Accuracy and Stability | System performance can deteriorate with time if there isn’t regular maintenance. | Include automated calibration tools as well as routine maintenance schedules, which include diagnostics. |

Applications Across the Print Industry of Inline Inspection

Packaging and Flexible Packaging

Inline inspection plays an essential part in packaging, where the visual consistency, clarity of print and brand integrity are not negotiable. The systems can detect issues like colors, registration errors, and printing voids in real-time making sure that each package meets the aesthetic and functional requirements. This is especially important in the case of consumer goods, where packaging is an important element of the product’s attraction.

Label Printing

In label production, especially for pharmaceuticals, cosmetics, and food products–100% inline inspection ensures barcode accuracy, text legibility, and color consistency. It checks that variable information like serial numbers, expiration dates and batch numbers are printed in a correct manner. These checks are vital to meet regulatory requirements and ensure traceability.

Pharmaceutical Printing

For inserts for pharmaceuticals packaging, blister packs, and medical labels, accuracy and compliance are essential. Inline inspection confirms the existence and accuracy of dosage directions along with legal disclaimers as well as regulatory symbolisms. OCR (Optical Character Recognition) and OCV (Optical Character Verification) functions make sure that printed characters correspond to the approved information, to avoid dangerous health and safety errors.

Security Printing

Security printing, including banknotes and stamps, certificates and ID documents–demands absolute accuracy as well as flawless replication of complicated patterns as well as counterfeiting capabilities. Inspection systems inline equipped with high-resolution cameras, as well as UV/IR lights verify microtexts, holograms, color shifting inks and other security components with extreme accuracy.

Commercial and Digital Printing

When it comes to commercial printing (such as catalogs, brochures and marketing collateral) consistency in layout and color are crucial. Inline inspection assures that each print is in line with the original proof for the entire print. In the case of variable and digital data printing, it confirms the integrity of the layout to ensure that personal content is properly set and aligned.

Corrugated and Carton Printing

For the folding and corrugated cartons industry, inline inspection can reveal problems with the structure, creases that aren’t aligned and issues with print registration that could affect branding and performance. This is particularly important for retail and e-commerce packaging where the appearance and durability are crucial.

Future Trends in Inline Inspection for the High-Speed Print Industry

The future of 100% inline inspection indicate the shift towards greater automation, more intelligent detection of defects, and greater integration into data-driven and digital workflows. These advancements will improve print inspection systems, not only more accurate but also more predictive, adaptable, and value-generating.

1. AI-Powered Defect Detection and Classification

Artificial Intelligence (AI) and machine learning are expected to revolutionize the detection of defects by making inspection systems able to differentiate from critical and not-critical flaws more effectively. Instead of relying only on pixel-to pixel comparison, AI algorithms can analyze past defect data, glean from feedback from humans, and then improve over time. This decreases false positives, and makes sure that operators are focused on addressing only problems that can be addressed, increasing productivity and minimizing the amount of interruptions.

2. Integration with Industry 4.0 and Smart Factories

As the printing industry adopts Industry 4.0 Inline inspection systems are now an integral component of smart factories’ ecosystems. Future systems will seamlessly share data with finishing lines, and software platforms like ERP as well as MES. Real-time communication allows automated decision-making, closed-loop controls as well as dynamic optimization of processes based on real-time high-quality data.

3. Cloud-Based Quality Monitoring and Analytics

Cloud integration can facilitate central tracking and analysis of several production lines and different locations. Managers of quality will have the ability use dashboards and defect maps and performance KPIs from a distance. This development supports greater transparency, remote troubleshooting, and faster response to quality deviations–particularly valuable in global or multi-site operations.

4. Automated Job Setup and Template Recognition

In the era of small prints and frequent job changes the future inline inspection systems will provide speedier and more automated set-up. With preloaded templates, smart image libraries, and automatic learning capabilities, these systems will cut down on the input of operators and reduce mistakes in setting up. This will be particularly beneficial to digital and variable-data workflows for printing.

5. Enhanced Inspection for Complex Materials and Print Effects

Future inspection systems are better equipped to handle difficult surfaces and finishes like metallic inks, holographic films varnishes, surfaces with textured textures. Imaging with multiple spectral frequencies (UV, IR, and visible light) and sophisticated lighting control will enable the detection of defects in a consistent manner even on reflections or surfaces that are visually complicated.

6. Roll Mapping and Defect Tagging for Downstream Use

Modern inline inspection systems can not only find defects, but also pinpoint their exact location on the roll or sheet. This permits precise rejection or automatic cutting downstream which is crucial when it comes to packaging, labelling processing, and conversion. Roll mapping increases the efficiency of material and guarantees a defect-free output during the conversion stage.

7. Sustainability and Waste Reduction Integration

Inline inspections will be a significant contributor to the sustainability goals. By reducing reprints and reducing waste and enabling more precise processes, these inspection tools assist manufacturers in reducing their carbon footprint. Future systems might also connect eco-monitoring tools in order to monitor and track the quality-driven savings in materials.

Summary

In the high-speed print industry, 100% inline inspection is no longer optional and it’s a necessity. By replacing outdated manual checks with intelligent, automated quality control, printers can reduce waste, uphold brand integrity, and maintain competitive advantage.