Print Inspection in Sustainable and Recyclable Substrates

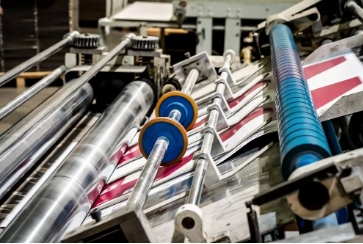

As the printing and packaging industries shift towards sustainability, the use of eco-friendly materials like biodegradable films, recycled paper and compostable laminates is growing rapidly. While these substrates help to reduce the environmental impact, they also present new challenges to print inspection systems. In order to ensure high-quality print on recyclable and sustainable substrates, requires special print inspection techniques, which take into account their specific characteristics.

Table of Contents

The Rise of Sustainable and Recyclable Substrates

Consumer demand for more eco-friendly products, paired with tighter regulations, has resulted in an increase in environmentally friendly printing materials. These include recycled post-consumer paper plants-based films, such as PLA and mono-materials specifically designed to recycle. But unlike conventional coated or plastic films These substrates typically have different texture, absorbency levels and color tones that can impact the quality of prints and inspection accuracy.

Why Print Inspection is Important for Sustainable and Recyclable Substrates

Maintaining Brand Integrity and Consumer Trust

Sustainable packaging typically has strong messages from the brand about the environment and accountability. Any printing defects, such as discoloration, smudges or a misalignment of the design can weaken the message and adversely affect the perception of consumers. An exhaustive inspection of the printed material ensures the appearance of the packaging accurately reflect the company’s commitment towards sustainability, thereby ensuring confidence and trust.

Reducing Material Waste and Environmental Impact

The reduction of waste is an essential concept of sustainability. In the early detection of print issues and with precision inspection systems can reduce rejecting materials and the need for reprints. This reduces not only production costs, but also the use of energy and raw materials involved in remanufacturing. This is directly helping to achieve environmental goals.

Complying with Regulatory and Industry Standards

A variety of sustainable packaging solutions require strict regulations regarding labels, safety information, and recyclability markings. An accurate print inspection will ensure that all important information is printed correctly and legible, which helps manufacturers adhere to the requirements of compliance and avoid costly recalls and fines.

Enhancing Production Efficiency and Cost-Effectiveness

The sustainable substrates are often more difficult for printing, which can lead to possible delays or even errors on your production process. Advanced print inspection gives immediate feedback to operators, allowing them to pinpoint and rectify problems. This improves productivity, reduces time to repair, and allows for the effective use of environmentally eco-friendly materials, without sacrificing quality.

Challenges in Print Inspection for Sustainable and Recyclable Substrates

| Challenge | Description | Impact on Inspection Accuracy |

| Surface Texture Variability | Natural fiber and recycled paper materials typically have rough or uneven surfaces. | Can cause false defect detection due to natural surface irregularities. |

| Color and Shade Inconsistency | Sustainable substrates can be colored differently between batches. | It makes it difficult to identify the actual color shifts in print or fades. |

| Variable Opacity and Reflectivity | Certain biodegradable film and recycled board have varying transparency or levels of light. | The camera-based defect detection process is impacted and can result in false positives or misses. |

| Dimensional Instability | Certain environmentally friendly films expand or shrink in response to heat or humidity. | This causes confusion in registrations and issues with alignment in printing. |

| Ink Absorption Differences | Materials that are porous or uncoated absorb ink differently. | Fine details can be blurred and decrease contrast to aid in defect detection. |

| Natural Imperfections | Fibers, specks or embedded particles are a part of recycled materials. | Could be mistaken as printing imperfections If algorithms are not adapted. |

| Compatible with eco-friendly inks | Inks that are UV-curable and water-based may react differently to sustainable substrates. | Alters defect appearance, making consistent inspection harder. |

Advanced Print Inspection Technologies for Sustainable and Recyclable Substrates

Advanced printing inspection solutions now combine cutting-edge imaging, artificial intelligence, adaptive algorithms, etc, to ensure accurate defect detection on sustainable and recyclable substrates without compromising print production efficiency.

1. Adaptive Imaging and Machine Vision Algorithms

Advanced 100% printing inspection systems employ adaptive imaging techniques to deal with the variability of substrates. Machine vision software is able to distinguish between normal features of the substrate, such as fibers, or minor color shifts and actual printing defects. Through constant adjustment of the threshold parameters and sensitivity to defects in real-time, these software systems reduce false positives that typically occur when using durable materials.

2. Integration of Multi-Spectral and Hyperspectral Imaging

The most exciting innovations is the inclusion of hyperspectral and multi-spectral imaging in the process of print inspection. These imaging technologies collect image data over a variety of wavelengths that go beyond visible light and provide detailed information on the interaction between substrate and ink. This allows for greater differentiation between texture on the substrate and actual imperfections like smudges, mistakes in printing, or color variations that aren’t readily detected by conventional RGB cameras.

3. Artificial Intelligence for Defect Classification

Artificial Intelligence (AI) plays an important part in enhancing the capabilities of print inspection. AI-powered systems can process huge quantities of images to detect complex defects and differentiate the acceptable variations that are found in sustainably-produced substrates. By using machines learning techniques, the systems continually improve their accuracy in recognizing defects and can adapt to changing substrates without needing extensive reconfiguration.

4. Real-Time Feedback and Production Optimization

Modern printing inspection technology provides real-time defect detection and report that allows immediate intervention in print process. This fast feedback loop decreases wasted time and effort, while which is in line with sustainability targets by reducing the footprint on the environment. The integration with management of production systems aids manufacturers to monitor the quality of their products and improve the parameters of printing specifically for sustainable substrates.

Future Directions of Print Inspection in Sustainable and Recyclable Substrates

As the demand for eco-friendly packaging and printed materials increases, the future of print inspection is expected to advance dramatically. Emerging new technologies and innovative approaches will help enhance defect detection accuracy, reduce waste, and support sustainable production goals more effectively than ever before.

1. Increasing Integration of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and machine learning are expected to play an a more important role in the near future of print inspection using sustainable substrates. These advances will enable inspection systems to learn autonomously as they adapt to distinct properties of various environmentally friendly substrates. As time passes, AI models will become highly specialized, decreasing false positives due to inherent substrate variation and increasing the detection of small imperfections that could have been difficult to spot.

2. Expansion of Multi-Spectral and Hyperspectral Imaging Techniques

The popularity of multi-spectral and hyperspectral imaging is anticipated to increase, giving greater understanding of ink and substrate interactions that go beyond visible light. Imaging techniques like these will allow inspection systems to analyse the physical and chemical characteristics of sustainable substrates in real-time. This will enable exact defect identification in demanding conditions like fluctuating lighting and textured surfaces.

3. Real-Time Analytics and Cloud Connectivity

Future web vision inspection systems during printing operations, will more often rely on the cloud and live analytics to improve the process of making decisions. Through aggregating information from inspections across production lines as well as geographic locations, companies can gain useful insights into quality trends in substrate performance, substrate performance, as well as process optimization. This data connectivity can facilitate pre-planned maintenance as well as proactive quality monitoring, which will lead to continual improvements in efficient printing operations.

4. Greater Compatibility with Digital Printing Technologies

As digital printing technology becomes more popular to create sustainable packaging, the inspection systems will be developed to seamlessly integrate into these technologies. The versatility of digital printing – offering shorter runs and more variable data — requires inspection systems that can handle different designs and materials efficiently. Future inspection technologies will facilitate this flexibility while ensuring strict quality assurance for recyclable materials.

5. Enhanced Environmental and Regulatory Compliance

With tighter regulations and increasing consumers’ expectations of sustainability, the technologies for print inspection will be increasingly equipped with features that help to ensure the environment. Systems can keep track of and document the use of substrates as well as ink formulations and the rate of defects to give transparent sustainability reports. This can help companies show their commitment to environmentally friendly practices and comply with regulations more quickly.

Final Thoughts

Print inspection in sustainable and recyclable substrates is a crucial step to make sure that the environmentally responsible packaging meets the same high-quality standards. With advancements in imaging technology, AI and adaptive algorithms, manufacturers can ensure the print integrity while also supporting sustainability goals.