How Web Guides Enhance 100% Print Inspection Systems

In the fast development environment of high-speed printing, delivering consistent print quality without defects is both a technical challenge and a market demand. To meet this demand, manufacturers are increasingly switching towards 100% print inspection systems that scan every centimeter of printed materials in real-time. A vital component that ensures the success of these systems is the web guide. Through maintaining precise alignment of the material, web guides ensure that the print inspection systems operate efficiently and with high accuracy.

Table of Contents

Understanding Web Guides

Web guides are electronic and mechanical devices that maintain the horizontal alignment of flexible materials — also referred to as “webs”–as they pass across a production line. They detect any deviations in web positioning and will automatically correct it by using sensors and actuators, to ensure that the web stays in line with the desired path.

Why Web Guides are Important in 100% Print Inspection Systems

Ensuring Stable Web Alignment

The basis of any inspection method is the notion that the printed material stays steady and centered when it is in the zone of inspection. Web guides are made to identify and correct lateral deviations from the web. Without them, the printed content can shift, wobble or move out of alignment, leading to inaccurate image capture and inconsistent examination results.

Improving Inspection Accuracy

The accuracy of the capture of images is essential for cameras with high resolution and sensors that can detect small imperfections, like blurring of text, color changes or issues with barcodes. If the web’s orientation is from its alignment the inspection system could overlook defects or mistakenly classify the areas that are not faulty as defective. Web guides ensure that the material is always within the field of view, ensuring the sharpness of the image and increasing the accuracy of detecting defects.

Reducing False Alarms and Waste

One of the most difficult issues when it comes to print inspection is avoiding false positives, instances in which the system detects an issue which isn’t really there. In most cases, misalignment causes errors as the system is unable to interpret the shifted print as being defective. Web guides decrease the chance of these errors by ensuring that the web is precisely placed. This improves the reliability of inspections, but also helps prevent the unnecessary rejection of products and materials waste.

Supporting High-Speed Production

Modern printing processes often operate at extremely high speeds in order in order to meet demands for production. With speed increasing the slightest movement of the web could have a major impact on the performance of inspection. Web guides are designed to react quickly and precisely keeping alignment even in dynamic conditions, allowing complete inspection that keeps up without compromising.

Integrating seamlessly with Inspection Systems

The latest web guides are becoming included in digital manufacturing environments. They can interact with printing inspecting systems and share information while making synchronized adjustments. This integration enables the automated process of quality control, it allows for adaptive alignment when there are shifts in the job and even pre-emptive maintenance alerts – enhancing the effectiveness and efficiency of the complete inspection process.

Advantages of Using Web Guides Enhancing 100% Print Inspection Systems

1. Maintaining Accurate Web Position

One of the major benefits that web guides have is the capability to keep the lateral orientation of the printed material as it moves through the zone of inspection. The majority of web inspection systems during printing operations employ high-resolution cameras or line scan sensors that capture photographs of printed materials. If the web shifts slight, the system might record images that aren’t aligned properly and result in low defect detection accuracy. Web guides can prevent this from happening by making adjustments in real-time to ensure that the web remains aligned, ensuring that each area is scrutinized precisely and in a consistent manner.

2. Enhancing Defect Detection and Image Clarity

Quality of information gathered from inspections directly relates to how steady the internet is at capture. Webs that are unstable or not aligned properly may result in blurred, cropped or misregistered images. This makes it more difficult for inspection software to differentiate between real imperfections or motion-generated artifacts. With the web guide installed it is able to pass through the cameras of inspection without lateral movements, which allows an accurate, high-quality image recording and more precise analysis of defects.

3. Reducing False Positives and Rework

A misalignment can be a significant reason for false positives when using printing inspection systems. A web that has been shifted may appear to be defective, even if the print is in fact accurate and can trigger alarms or stoppages and even the need to rework. Web guides significantly minimize the danger by keeping the web stable, which ensures that only real defects are detected. This leads to less false alarms, fewer inspection mistakes, and increased confidence of the inspector during the inspection process.

4. Minimizing Waste and Production Downtime

If false positives are less frequent and defect detection becomes more precise, companies can minimize waste of material and reduce downtime for machines. Web guiding systems assist in avoiding unneeded line stops due to uncertainties in inspections, as well as making sure that there is no costly disposal of material that is acceptable. In time, this will translate into better utilization of resources as well as a higher productivity.

5. Supporting High-Speed Printing Operations

With the increase in printing speed the sensitivity to web alignment issues decreases. If there is no proper direction, fast webs tend to drift more easily that can overwhelm the most sophisticated inspection equipment. Web guides are engineered to operate at a high rate of response and adjust web alignment fast and precisely during high-speed printing production runs. This is why they are crucial for ensuring consistent performance of inspections in harsh environments.

6. Integrating Automation with Inspection Workflows

Modern web guides are coupled with inspection systems and production control platforms to create a closed loop quality assurance process. Information taken from inspection systems will be used to inform the web guide to perform real-time corrections, and the guide’s web interface can transmit positional information back to increase the accuracy of inspection. This integration level allows better workflows for detecting and correcting defects which will lead to innovative Industrial 4.0-enabled print lines.

Key Technologies in Web Guide Systems for 100% Print Inspection Systems

| Technology Component | Function | Role in 100% Print Inspection Systems |

| Web Edge Guide Sensors | Determine the location of web edges by using ultrasonic, infrared or optical techniques | You can ensure that lateral tracking is accurate, regardless of variations in print |

| Line/Contrast Sensors | Find marked lines, printed lines or contrast differences in the web | Guide your printer by printing registration. perfect for printing on substrates |

| High-Resolution Cameras | Record precise web positioning or printed fiducials | Provide advanced web guiding capabilities and aid in alignment of print-to-camera |

| Servo Actuators | Perform quick exact changes to web’s lateral positioning | Maintain a stable alignment even at high speeds, vital for inspection precision |

| Web Guide Controller | Processes sensor data and then sends commands to actuators. | Coordinates real-time corrections in order to maintain an optimal position on the web. |

| Steering Frames/Pivot Guides | The web is moved mechanically in the direction it should be. | Perform physical movements without introducing tension, or wrinkling |

| Closed-Loop Feedback System | Continuously adjusts itself based on the live sensor input | Stability and accuracy are improved in the face of changing conditions |

| Communication Interfaces | Connects to inspection systems using protocols like Ethernet/IP, or Modbus | It allows the synchronization of 100 percent inspection systems and Integration into smart lines |

Applications of Web Guides in Print Production

| Print Production Area | Application of Web Guides | Benefits |

| Label Printing | Aligns narrow webs of wires for cutting dies and for inspection | It ensures accuracy in registration and decreases the amount of waste material |

| Flexible Packaging | Maintains print-to-laminate alignment during high-speed runs | Improves sealing accuracy and enhances visual quality |

| Pharmaceutical Printing | Guides printed on blister packs or labels printed with high-precision | It ensures that the text is read and in the strictest standards for regulatory compliance. |

| Security Printing | Secure marks are kept in place and fine print precisely aligned | Keeps the integrity of anti-counterfeit security features |

| Commercial Printing | Stabilizes large-format catalogs, brochures, and flyers | Reduces the risk of image misalignment and increases finish consistency |

| Newspaper Printing | Controls large high-speed webs via intricate roller systems. | Reduces wrinkles and improves accessibility across multiple pages |

| Ticket & Tag Printing | Guides have narrow webs, with variable information and perforation lines | It ensures accurate cutting or folding as well as barcode alignment |

| Digital Printing | Supports substrates with variable widths and short-run variations. | Improves the flexibility and consistency of inspections during job switchovers |

Future Outlook of Web Guides in 100% Print Inspection Systems

As print production becomes faster, more automated, and quality-driven, web guide systems are expected to evolve alongside 100% print inspection technologies. These systems are no longer just mechanical aids for alignment and they are becoming intelligent, integrated, and predictive tools that play a key role in achieving zero-defect print production.

1. Integration with Industry 4.0 and Smart Manufacturing

The future web guide systems will be integrated into larger manufacturing automation and smart factory platforms. Through connectivity protocols like OPC UA, MQTT, or Ethernet/IP, guides on the web will share real-time information with PLCs, inspection systems, or cloud platform. The sharing of data can lead to the optimization of processes in real-time, automated job shifts, and more intelligent making decisions on the production floor.

2. AI and Machine Learning-Driven Control

The use of machine learning and artificial intelligence will enable guides on the web to adjust to complicated print patterns as well as changes in the material’s behavior. Learning from past alignment data and trends in print defects future systems will anticipate alignment issues before they happen and then proactively adjust the behavior of the guide which will reduce waste while increasing the accuracy of inspections.

3. Predictive Maintenance and Diagnostics

Instead of relying on regular inspections or reactive maintenance, future web guides will include devices and sensors to monitor wear, vibration and the time to respond. This will allow proactive maintenance, in which the system will alert operators prior to mechanical problems or a change in performance can affect the reliability of inspections.

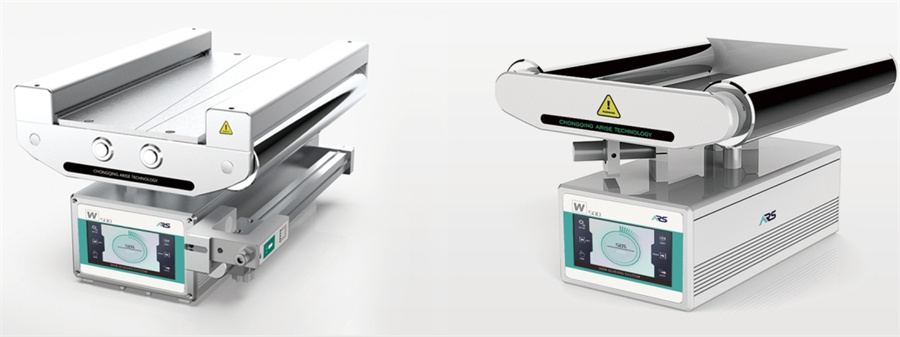

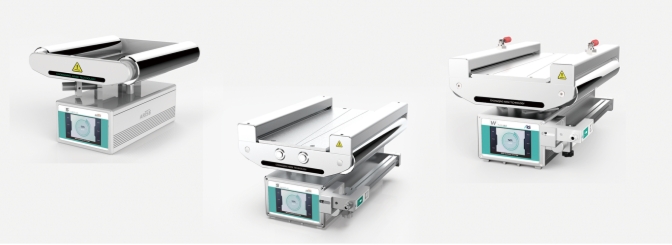

4. Compact, Modular, and Retrofittable Designs

As space becomes more important when it comes to integrated print inspection systems, web guides for printing will soon be constructed with smaller and more modular forms. They will be able to easily be retrofitted into existing lines without major changes and also to adapt to the ever-growing use of narrow-web and multi-web configurations in the latest printing software.

5. Improved Feedback Loops Using Inspection Cameras

Web guides of the future will have advanced feedback systems that are directly connected to cameras for inspection. Instead of relying on contrast or edge sensors, they could receive data on visuals through the system of inspection itself in order to ensure optimal printing registration. This closed loop control will permit sub-millimeter corrections to be made in real time even in the midst of rapid web acceleration or slowing down.

6. Sustainability and Energy Efficiency

As the importance of environmental sustainability becomes more central in manufacturing, future web guides will focus on components that are low in power, less use of air (in pneumatic system) as well as energy-efficient motors for servos. Their function in reducing the amount of waste resulting from print misalignment is also a major sustainable driver.

Final Thoughts

Web guides are indispensable for ensuring precision and reliability in 100% print inspection systems. Through maintaining stable web alignment, they make sure that sensors and inspection cameras are able to capture and analyze every part of printed material precisely. In an industry where accuracy and waste reduction are crucial, adopting high-quality web guiding systems is essential for printers aiming to achieve flawless results and competitive advantages.