The Synchronization of Edge and Tension Control in Web Guide

Modern manufacturing operations involve continuous webs of material including plastic films and paper to metal foils and textiles. Maintaining a precise web guide is crucial to ensure product quality and efficiency in operation. The key to this precision is the integration of two key subsystems which includes edge control and tension control. Although each has an individual purpose and their synchronization in web guide systems is crucial for achieving stable and optimized web handling.

Table of Contents

Understanding Edge Control and Tension Control in Web Guide

Edge Control in Web Handling

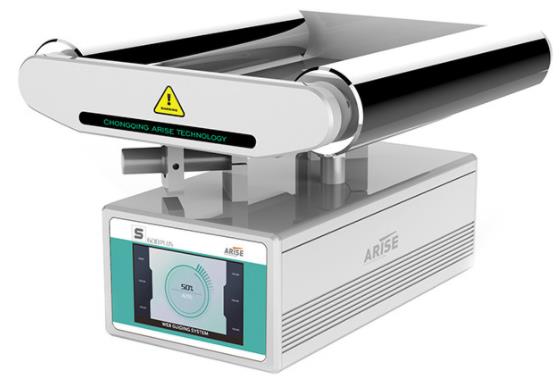

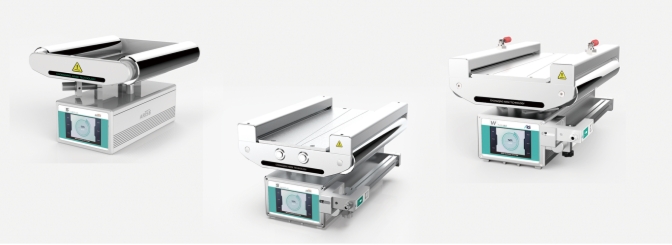

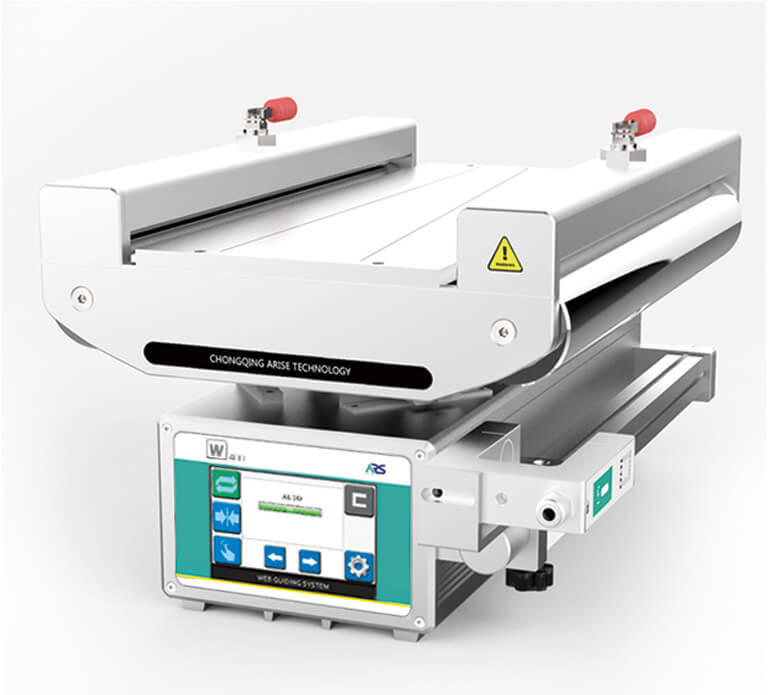

Edge control systems are created to ensure the horizontal alignment of a shifting web. By detecting the edges of the web via sensors and performing real-time adjustments to its position with actuators the device stops any misalignment, the web edge guiding control system is crucial for applications where the web has to pass through equipment with narrow sides like printers, laminators, or slitters. Without precise edge control any slight deviations could result in problems like printing registration errors and uneven coatings, as well as materials waste.

Tension Control in Web Processing

While edge control is responsible for horizontal movement and tension control ensures the web is pulled by the same force throughout its goes through the system. This is essential in order to prevent problems such as stretching, wrinkles or tearing that can arise when tension on the web changes over the limits of what is permissible. Tension control systems utilize the use of dancer arms, load cells or motor feedback to monitor and alter the force of pulling dynamically. The maintenance of tension is particularly crucial when working with thin, elastic or multilayered materials.

Why Need the Synchronization of Edge and Tension Control in Web Guide

The Interdependency Between Edge and Tension Control

Although edge and tension control systems operate in a way that is independent but they interact directly. A change made to the correct edge location could result in localized tension changes, particularly when the web is required to move through curved rollers, or sudden changes in direction. In contrast, a change in tension of the web can cause it to cause the web to move laterally and cause the edge to shift. When each system reacts in isolation, they may begin to overcompensate–leading to process instability, quality degradation, or even machine stoppage.

This interdependence creates the need for the synchronization. Instead of operating as separate components that are independent, the tension and edge controls need to work in concert. This way they can ensure a smooth and steady flow of material across all machine zones regardless of changes in speed or shifts in the diameter of rolls or inconsistencies in the material.

The Importance of Synchronization

Synchronization makes sure that tension and edge corrections are in sync. When web edge guide sensors detect a misalignment The control system analyzes current tension data prior to applying correction. In the same way, adjustments to tension are done with a keen awareness of the web’s position. This prevents overcorrections, reduces mechanical stress on the web and permits better, more steady movement along the line. It also permits faster operations without sacrificing precision.

Key Benefits of Synchronizing Edge and Tension Control in Web Guide Systems

Improved Web Stability

One of the primary advantages of synchronized edge tension control is improved web stability. If lateral corrections are performed via the edge guide, the synchronized tension control makes sure that these adjustments are not causing stretching, slack or wrinkles. Also, if the tension of the web changes due to fluctuations in speed or a change in the diameter of unwind/rewind rolls the edge guide responds to the changes in proportion, while maintaining a constant position. This real-time coordination reduces the effects of vibration, misalignment and web oscillations, particularly when operating at high speeds.

Enhanced Product Quality

The quality of products is directly influenced by the location and the quality of web. Incorrect alignment can lead to an off-center print, coating defects or even cutting mistakes, as well as improper tension that can lead to stretching deformation or breakage. Synchronization assures that any shift in the edge’s position is followed by a proper tension adjustment, and the reverse is true. This balance allows for consistency of the product and allows for high-precision processes, like lamination, multi-color printing or cutting.

Increased Production Speed

When tension and edge control systems are coordinated they are able to react to changes faster as well as without delays. This flexibility allows the whole production line to run at greater speed, with less possibility of material damage. High-speed printing, laminating or coating lines benefit from this ability because it guarantees that the quality and efficiency can be optimized at the same time.

Reduced Waste and Downtime

In unsynchronized systems, inadvertent corrections and feedback that conflict can result in material defects and inadvertent delays. Synchronization can greatly ease these problems by synchronizing the responses from both systems which results in fewer errors and lower downtime. In time, this can lead to substantial savings in materials as well as time and energy.

Longer Equipment Lifespan

When tension control and edge are in conflict and are in conflict, it puts an extra load on rollers, motors actuators and other mechanical components. Synchronization helps reduce unnecessary tension and sudden motion changes and reduces wear and wear. In the end, components last longer and maintenance intervals are prolonged and the total cost of ownership is decreased.

Greater Flexibility for Advanced Materials

Modern manufacturing usually includes delicate or composite materials, such as ultra-thin film as well as stretchable webs or multilayer laminates. The materials they are made of can be more prone to variations in alignment and tension. A synchronized control system allows more efficient handling of these materials by changing their physical properties in real-time. This flexibility broadens the selection of materials that are efficiently and safely handled.

Support for Smart Automation and Digital Integration

As web handling systems progress towards fully automated systems as well as industry 4.0 connectivity, synchronization is an essential requirement. Control systems that are centralized, smart algorithms as well as high-speed communications protocols permit the edge and tension systems to function in a single and adaptive process. This enables closed-loop control predictive maintenance, as well as remote monitoring, the key features of modern smart factories.

Key Synchronization Methodologies for Edge and Tension Control in Web Guide

1. Centralized Control Architecture

The most efficient methods of synchronization is using a central control system that is able to manage both tension and edge control loops. In this configuration the single programable logic controller (PLC) or industrial PC is able to receive input data from edge sensors and tension feedback devices, such as dancer arms or load cells. The central controller analyzes the data using controlled algorithms and sends coordinated control commands to motors and actuators.

This technique allows the real-time coherence between edge position adjustments and tension responses. It prevents the possibility of conflicting signals and also reduces delay, especially in web-based processes that are high-speed. Centralized control also permits the integration of sophisticated techniques and user interfaces to provide improved process visualization and diagnosis.

2. Integrated Sensor Feedback Systems

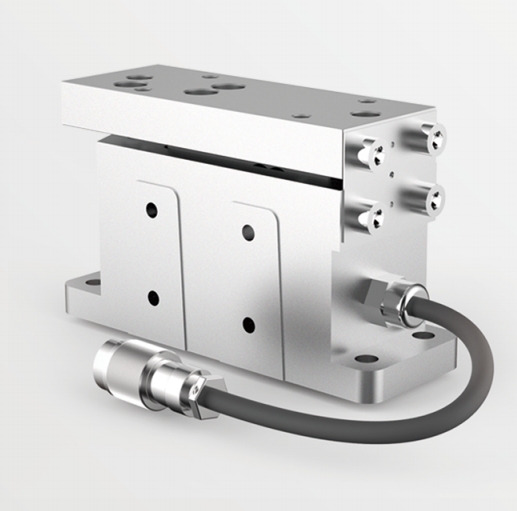

Another efficient method is using integrated sensor networks in which edge sensor and tension sensor are connected and are able to communicate directly. The system’s architecture is designed to permit each sensor to analyze the data of the other. For example, if the edge sensor detects a misalignment it transmits a signal to correct the misalignment for the actuator that guides edges after verifying that the tension levels are within a safe range. In contrast, if the load cell detects a abrupt drop in tension and it is able to temporarily restrict edge correction movements to prevent the risk of causing instability.

This type of sensor-to-sensor communications allows for uncentralized, yet synchronized actions which is particularly useful in retrofitting or modular Web guide system.

3. Coordinated Drive Control

In web guiding systems, driven by multiple motors–such as those at the unwind, processing, and rewind sections–coordinated drive control plays a crucial role in synchronization. In this manner, servos and variable frequency drives (VFDs) are designed to operate in tandem by sharing edge position and tension control information. Drive systems with web-handling software can alter the speed and torque dynamically to control tension and alignment.

For instance an actuator in a drive system might change its speed for a motor for a tension zone in the event that an edge guide actuator performs an adjustment, ensuring uniform tension during lateral web movements. This technique is heavily reliant on the real-time protocols like EtherCAT, CANopen, or Profinet to ensure fast and secure data exchange.

4. Adaptive Control Algorithms

Adaptive control is a sophisticated method of controlling that makes use of algorithms that predict or use real-time analytics to alter the parameters of control. These algorithms are able to understand the effects of tension changes on the edge’s position, and reverse. They can then adjust the speed of correction as well as thresholds as well as the timings of each system in accordance with the results.

For instance, if the possibility of a sudden drop in tension is anticipated (e.g. in the course of the acceleration of a roll) edge control systems can preventively decrease the actuator’s correction rate to prevent overshooting. This type of control is extremely useful when dealing with materials that are variable or the frequent change of production settings.

5. Virtual Master-Slave Configuration

In certain web guiding control systems, synchronization can be achieved by using a virtual master-slave setup in which the control loop (typically tension control) serves as the main reference, while the control loop at edge performs in a reactive or dependent function. This configuration simplifies the system’s architecture and offers a predictable response pathway. For example edge correction may be only performed once the tension is stabilized to an appropriate level, which will ensure security and reducing the possibility of overcorrection.

This technique is beneficial for situations where a particular control objective, typically tension, is given a higher importance due to the brittleness of the material that is being handled.

6. Digital Twin and Simulation-Based Tuning

With the rapid development of simulation technology, a few manufacturers are using digital twin techniques to model and improve the timing of tension and edge control before commissioning the system. Digital twins mimic the behaviour of the rollers, webs drives, as well as control systems in different operating conditions. Engineers can make use of these simulations to fine-tune parameters for synchronization, establish the most optimal delay time and evaluate the effect on disturbances.

This reduces the time and effort that is required on the floor of production and allows the systems to be designed for material-specific behaviour.

Industry Applications of the Synchronization of Edge and Tension Control in Web Guide

| Industry | Application Description | Typical Materials Handled |

| Printing | Keeping precise registration of prints and alignment | Paper, film, flexible packaging materials |

| Flexible Packaging | Multilayer coating and laminating films | Plastic films, foil laminates |

| Textile Manufacturing | Controlling tension of fabric and alignment when weaving or finishing | Nonwoven and weaved textiles |

| Battery Manufacturing | Separators and thin electrodes for lithium-ion batteries | Thin metal foils, polymer separators |

| Paper Converting | Slitting, rewinding and embossing webs of paper | Paper rolls, cardboard sheets |

| Film and Foil Industry | Extrusion, casting and coating of foils made of metal | Plastic films, aluminum foil |

| Medical Device Fabrication | Processing films that are thin and sensitive to create sterile packaging | Laminates, polymeric films |

| Solar Panel Manufacturing | Processing delicate photovoltaic films and substrates | Thin glass, polymer films, and thin glass |

Technological Trends in Synchronizing Edge and Tension Control in Web Guide Systems

As web-handling processes become faster and materials more advanced, the requirement for precise synchronization between edge and tension control has driven significant technological innovation. These trends not only enhance precision and reliability but also allow for smarter, more flexible manufacturing.

1. Advanced Sensor Technologies

The latest generation of sensors incorporates edges detection and tension measurements into a single units, which reduces complexity while increasing response times. These sensors typically come with greater resolution, higher sampling rates, and higher environmental resistance, which allows for more precise real-time feedback for sync.

2. AI and Machine Learning Integration

Artificial Intelligence (AI) as well as machine-learning algorithms are integrated into control systems in order to anticipate disturbances prior to their occurrence. By studying historical and real-time information, AI can optimize the interaction between tension and edge control, increasing the ability to adjust and reduce oscillations or overshoots.

3. High-Speed, Real-Time Communication Protocols

Protocols like EtherCAT, Profinet, and TSN (Time-Sensitive Networking) provide ultra-fast, reliable communications between controllers, sensors and drives. This makes sure that synchronization commands and feedback is exchanged at a minimum latency, which is essential for high-speed internet lines.

4. Integrated Motion Control Systems

Modern motion controllers and servo drives have web-based handling features built into them that allow simultaneous tension and edge control on a single hardware platform. This eases the complexity of systems and increases synchronization with tightly connected control loops.

5. IoT and Cloud Connectivity

Internet of Things (IoT) integration permits web guide systems to send synchronization information to cloud platforms to monitor remotely, diagnose and predictive maintenance. Cloud-based analytics can help detect problems with synchronization before they affect production, and allows for proactive interventions.

6. Energy-Efficient and Compact Actuators

The advancement of smaller and energy efficient actuators (such direct-drive motors as well as piezoelectric actuators) can provide rapid and precise edge corrections while consuming less energy consumption. The actuators are more responsive to improve synchronization tension control.

Final Thoughts

The synchronization of edge and tension control in web guide is crucial to ensure high-quality, flawless and efficient production. As manufacturing progresses towards higher automation and better precision, this integration of these systems is becoming increasingly essential. Through ensuring real-time coordination between edge and tension control, manufacturers can maximize productivity while minimizing waste and downtime.