How Digitalization is Improving Tension Control in Industrial Automation

Tension control is an essential component of industrial automation, specifically when it comes to processes that require continuous materials such as paper, textiles, films, wires, metals, etc. A precise tension control system ensures high quality products, decreases the amount of waste, improves safety, and extends the life of equipment. With the rapid advancement of digitalization, traditional tension control systems have evolved significantly, becoming smarter, more responsive, and more adaptive. This article delves into how digital technologies are revolutionizing tension control across various industrial applications.

Table of Contents

The Limitations of Traditional Tension Control

1. Slow Response Time to Process Changes

Tension control techniques of the past are based on mechanical feedback loops as well as analog controls that do not respond rapidly to abrupt shifts in speed or material properties, as well as web tension variations. This slow response time often results in inconsistent tension, that can lead to problems with the product, like stretching, wrinkles or snapping.

2. Limited Accuracy and Sensitivity

Analog load sensors and tension sensors employed in older systems generally have issues with signals drift, resolution limits and electrical noise. These factors reduce the accuracy and sensitivity of tension measurements, making it difficult to maintain tight tolerances–especially in high-precision applications.

3. Poor Flexibility and Scalability

Traditional system for controlling tension are built with set configurations and a hardwired logic. The ability to adapt them to various types of materials and tension zones or even new setups for machines often necessitates manual calibration or adjustments to the hardware. This inflexibility hinders effectiveness in situations where frequent product replacements are required or differing speed.

4. Maintenance-Intensive Components

Mechanical elements such as magnetic powder brakes or tension arms, and rollers are susceptible to wear as well as require periodic maintenance. They can be disaligned, lose calibration or degrade over time which causes tension instability and downtime in production.

5. Lack of Integration and Data Visibility

The traditional systems are typically standalone and are not able to easily connect with central controls or networks of data. The lack of integration results in the operators aren’t able to see system performance, and they are not able to use real-time analytics or preventive maintenance strategies.

6. Inability to Meet Modern Automation Demands

Modern industrial automation requires systems that are adaptable self-correcting and capable of coordinating complex tasks across multiple zones. The traditional tension control system aren’t equipped with the ability to communicate and have the necessary intelligence for modern automation, making them obsolete in intelligent factories.

The Role of Digitalization in Tension Control

With the use of intelligent sensors and real-time data and networked automation, the digitalization process can elevate tension controls to new heights in accuracy, reliability and effectiveness.

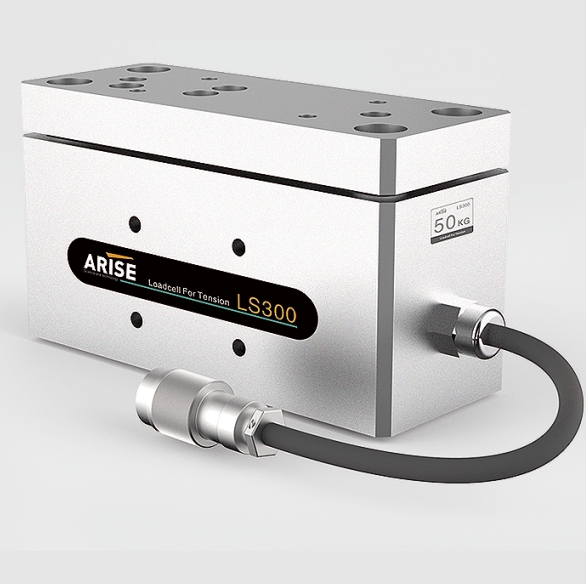

1. Accuracy through High-resolution Digital Sensing

Digitalization starts with better sensing. Modern digital load cells encoders, encoders, and tension transducers give accurate continuous measurement of tension on the web and line speed and material place. In contrast to analog sensors, which are susceptible to drift, noise, and problems with calibration, modern tension sensors produce clear and consistent signals. This improved precision guarantees that tension deviations are found and corrected immediately, allowing you to keep the same level of uniformity when working in high-speed, multi-zone production environments.

2. Adaptive Control Enabled by Advanced Algorithms

Digital tension controllers equipped with adaptive algorithms like PID (Proportional-Integral-Derivative), fuzzy logic, and model predictive control enable real-time tension adjustments. They continuously evaluate feedback data and then automatically adjust control outputs to ensure the best performance. This ability to adapt is crucial in the case of working with different materials or transferring between batches of products, since it eliminates the requirement for manual calibration and guarantees constant tension even under different conditions.

3. Seamless Integration Industrial Automation Networks

Electronic tension control devices are integrated into large-scale factory networks using the standard industrial communication protocols, like PROFINET, EtherCAT and Modbus. This integration permits the operation of synchronized across several zones or machines or lines. It also permits centralized control via SCADA and MES platforms, which provide operators with a single interface for monitoring real-time tension information as well as alarms and performance metrics.

4. Enhanced Visibility and Remote Monitoring

Digital systems allow you to gather, record and display tension data in real-time. Data is accessible on site or remotely, allowing engineers and operators to analyse the behavior of the system, spot inefficiencies, and take decision-based on data. Trend charts, dashboards, and alert systems increase transparency into tension management, decreasing the time to respond and increasing the overall efficiency of the line.

5. Predictive Maintenance and Operational Insights

With the aid with the help of Industrial Internet of Things (IIoT) connectivity Digital tension control systems are able to collect long-term operational information and apply analytics to identify potential failures. For instance an rise in tension may be a sign of wear on the roller or a sensor in danger of failing. By addressing these issues prior to they lead to downtime Predictive maintenance techniques improve reliability of the system as well as reduce operating expenses.

6. Optimization via Digital Twins

Digital twin technology goes one leap further with the creation of an imaginary model of the tension control system’s physical structure. The simulation environment lets engineers test different configurations and models, test changes to production and improve control parameters without disrupting real processes. Digital twins speed up the design of systems commissioning, troubleshooting, and design and can be an effective tool for training operators.

Industry-specific Benefits of Digitalization in Tension Control

| Industry | Application | Benefits of Digital Tension Control |

| Packaging | Flexible packaging films, foils, and laminates | – Consistent tension during high-speed winding – Reducing film wrinkling and tears |

| Printing | Offset, flexographic and digital printing | Print registration with enhanced print quality Minimized misalignment as a result of real-time adjustments in web tension |

| Textiles | The weaving of fabric and dyeing process, and finishing | – Prevents stretching of fabric – Adaptive control for varying material properties |

| Paper & Pulp | Paper converting, slitting, coating | – Reducing paper breaks and web flutter – Increased tension across multiple processing zones |

| Metals | Rolling of aluminum and steel and Slitting | – High tension accuracy for the most delicate metals – Reduced material distortion coil handling |

| Electronics | Flexible circuits and handling of lithium battery films | – Precision tension for ultra-thin substrates – Protection from static deformation as well as tearing |

| Tire and Rubber | Tire cord winding, rubber sheet processing | – A uniform tension for consistent cord position – Enhanced control during rubber elongation |

| Converting & Laminating | Multilayer Material Processing | – Multi-roll systems that are tightly synchronized – Reduction of air entrapment and material delamination |

| Cable & Wire | Insulation, extrusion and coiling procedures | – Managed tension to prevent breaking or stretching – Improved consistency of lay in spooling |

Summary

Digitalization is transforming tension control into an integrated, intelligent and autonomous function of industrial automation. Through the integration of real-time data, predictive analytics, and intelligent connectivity, industries are now able to achieve new levels of efficiency, precision and flexibility. As the digital technology continues to advance, tension control will be ever more sophisticated, scalable and more and more vital for the intelligent factories of the future.