How To Improve Production Efficiency Of Masks With Arise Web Guide System

The masks are regarded as a key resource for the prevention and control of the epidemic. Due to technical issues, the contradiction between supply and demand is prominent with a huge supply and demand gap. However, the technical deficiencies of mask machines have caused raw material waste and reduced output. This phenomenon will be greatly improved after installing the Arise web guide system.

Why Choose Arise Web Guide System For Mask Production?

During the coil winding process of the mask machine, once the edges of the coil are out of alignment, the subsequent production process will lead to material waste and machine shutdown for debugging. Therefore, in the production of coil products, the web guiding system is an indispensable key accessory. Arise web guide machine is a product that uses photoelectric technology to solve the problem of material waste and multi-layer material bonding in mask production. Its innovation is that it can reduce the waste of mask melt-blown cloth by 30% and solve the five-layer bonding problem of N95 masks, which improves the production speed and qualification rate of masks, as well as improving the production efficiency of masks and reducing labor costs.

How Does The Arise Web Guide System Work On Mask Machine

The production of masks includes polypropylene particles to medical non-woven fabrics, through the processing of mask machines, and then strictly disinfected. The shortage of medical masks always is caused by insufficient production of the mask machines. The Arise web guiding system has greatly improved the working efficiency of the mask machine through technological innovation.

The web guide sensor emits infrared light, ultrasonic, laser, visible light to monitor the operation of the coil materials, and sends the signal to the controller. The controller finds the position drifts of coil materials, according to the instruction set by the controller in advance, the driver controls the swing of the frame to guide the coil position. The automatic web guide system adopts a photoelectric sensor detecting the edge position of the coil materials, and the measured position deviation signal is sent to the controller. After the judgment and processing by the control unit, the drive motor is controlled to guide the coil with the deviation position to the correct position.

Benefits Of Using Arise Web Guide System For Mask Production

After the mask machine is equipped with the Arise web guide system, the production speed can be increased to 500 pieces/minute, and the N95 (KN95) mask machine can be increased to 3000 pieces/minute. It can perform differential and swing by tracking the edge of the working coil materials. It supports EPC which is the abbreviation of edge position control and LPC, the abbreviation of line position control, with ultra-thin melt-blown cloth custom sensors and adjustable tension.

The web guide machine uses a 940nm infrared emitter tube and imported silicon photocells to accurately detect the deviation of the melt-blown cloth. The drive system adopts low synchronization, frequency conversion speed regulation, stepping and servo motor drive. The stroke is strictly proportional to the offset of the coil materials. The servo motor drives the ball screw to precisely adjust the material deviation, and keep the edges and lines of coil materials at the designated position at any time The microcomputer digital controller provides accurate control for the various functions of the system. The machine adopts a full touch screen operation, which is simple and easy to use. The operation interface includes the languages of 8 countries, which is convenient to operate all over the world.

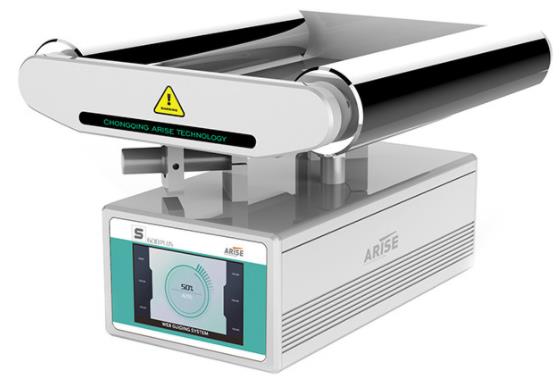

Arise Web Guide System Manufacturer – Arise Technology

Arise Technology, which is the manufacturer of the Arise web guide system, is located in Chongqing, China, It is a high-tech enterprise specializing in the research and development, production, sales and service of high-tech industrial automation products. It focuses on the R&D and production of the web guiding system and tension control system with 15 years’ experience. Arise attaches importance to product quality, high technology and product innovation, and strives to provide advanced level products.

The products manufactured by Arise technology is simple to operate with high precision, good stability, a wide range of applications. They can track and correct the marking lines or edges of cardboard, film, aluminum foil, steel tape and other much more materials to ensure neat winding and slitting. They are widely used in packaging, film, printing, printing and dyeing, labeling, textile, steel, tire, battery and other more industries. With excellent quality products with innovative technology and professional service, the Arise products are sold all over the world and get a high reputation among customers.

Summary

At present, masks are in huge demand all over the world. Arise web guide system can reduce the waste of raw materials and the shout-down of mask machine, improving the production efficiency of the masks, thereby effectively solving the shortage problem of the masks.