The Significant Role of Precise Tension Control on Energy Efficiency and Material Savings

In the dynamic landscape of manufacturing and industrial processes, the pursuit of energy efficiency and material savings has become increasingly paramount. Precise tension control plays a pivotal role in optimizing energy efficiency and material savings across various industries. From textiles and paper to metals and beyond, maintaining precise tension levels ensures a streamlined production process, minimizes waste, and contributes to a more sustainable and cost-effective operation.

Understanding Tension Control

The modulation and preservation of tension inside a material as it progresses through several stages of production is referred to as tension control. Achieving precise tension control is critical since it directly influences the final product’s quality, production speed, and resource consumption.

How Tension Control Influences Energy Efficiency

1. Motor Power Optimization

Precise tension control allows for the fine-tuning of motor power based on the specific requirements of the production process.

By maintaining optimal tension levels, motors can operate at their most efficient points, reducing energy consumption and minimizing waste.

2. Reduced Heat Generation

Inaccurate tension control can lead to excessive friction and heat generation within machinery.

Precise tension control minimizes these issues by preventing unnecessary strain on components, thereby reducing energy losses due to heat.

3. Minimized Energy Waste

The energy input to the production system is better aligned with actual needs when tension is accurately regulated.

This reduces the amount of energy wasted when procedures are run at higher-than-necessary power levels.

4. Optimized Production Speed

Maintaining stable tension levels enables for the optimization of production speeds without sacrificing final product quality.

Operating machinery at optimal speeds ensures that energy is used efficiently, contributing to overall energy savings.

5. Prevention of Abrupt Tension Changes

Unexpected fluctuations in tension can cause spikes in energy usage and strain on equipment.

Precise tension control aids in the prevention of abrupt tension variations, resulting in a more stable and energy-efficient industrial environment.

6. Extended Equipment Lifespan

Uncontrolled tension variations can add to equipment wear and tear, shortening its lifespan.

The longevity of equipment is extended by maintaining accurate tension levels, minimizing the need for frequent replacements and saving the associated energy costs of constructing new apparatus.

7. Improved System Reliability

Consistent tension control improves the overall reliability of the production system.

Reliable tension controllers require fewer energy-consuming stoppages and have a lower error rate, which contributes to better energy efficiency.

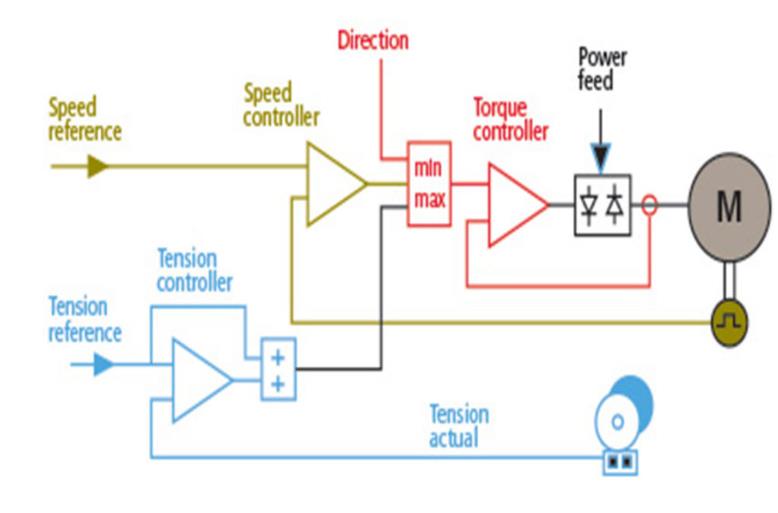

8. Energy-Aware Control Systems

Advanced tension control systems are frequently combined with energy-conscious control technologies.

These systems can optimize tension levels in real-time, taking into account variations in material properties and external factors, further enhancing energy efficiency.

How Precise Tension Control Contributes to Material Savings

1. Waste Reduction

Consistent tension control prevents material defects, misalignments, and breakages during the production process.

By maintaining uniform tension, manufacturers can minimize the occurrence of flaws, resulting in a significant reduction in material waste.

2. Optimized Yield

Precise tension control allows manufacturers to operate machinery at optimal speeds without compromising the integrity of the material.

This optimization results in higher yields as each unit of material is processed efficiently, contributing to substantial material savings over time.

3. Enhanced Product Quality

Uniform tension throughout the manufacturing process produces high-quality goods with minimum variance.

This consistency is critical for meeting or surpassing client expectations while minimizing faults and rejected goods.

4. Prevention of Overstretching or Distortion

Improper tension control can cause overstretching or distortion of materials, resulting in useless or poor goods.

Precise tension control prevents these issues, ensuring that materials are processed within specified limits and preserving their structural integrity.

5. Minimized Set-Up Scrap

During the setup and adjustment phases of production, precise tension control allows for quicker and more efficient calibration of machinery.

Reduced setup time minimizes the amount of scrap generated during the initial stages of production, contributing to material savings.

6. Extended Material Lifespan

Excessive stress can contribute to premature material wear and tear.

The lifespan of materials is extended by maintaining ideal tension levels, decreasing the need for frequent replacements and saving material use.

7. Reduced Rejected Batches

In processes where tension control is critical, such as printing or coating applications, precise tension control minimizes the likelihood of producing batches that do not meet quality standards.

This reduction in rejected batches directly contributes to material savings by avoiding the disposal of substandard products.

8. Improved Process Efficiency

Precise tension control streamlines the entire production process, minimizing interruptions and errors.

Improved process efficiency contributes to material savings by lowering the requirement for rework or additional raw materials to compensate for defects.

Conclusion

Manufacturers must realize the critical importance of accurate tension control in their manufacturing processes in their persistent pursuit of sustainability and operational efficiency. Businesses may improve energy efficiency, decrease material waste, and improve product quality by investing in modern tension control systems. Adopting precise tension control is more than simply a strategic business decision; it also corresponds with the global drive toward sustainable and responsible manufacturing methods. As industries grow, harnessing the potential of precise tension control is critical to unlocking a more sustainable, efficient, and economically viable future.