Edge-to-edge Printing Inspection in Narrow and Wide Webs

For a printing business, ensuring consistent quality across the entire substrate, particularly from edge-to-edge, is crucial. Due to the increased demand for flawless packaging and label printing, edge-to-edge printing inspection have become essential components in both narrow and wide web printing environments. These print inspection systems not only detect print defects in real time but also help ensure the integrity of the brand and minimize waste material.

Table of Contents

Why Edge-to-Edge Printing Inspection is Important

Edge-to-edge printing inspection plays a crucial role in printing operations by detecting defects at one edge of the print to next in real-time. Its importance goes beyond aesthetics, impacting the performance of products, regulatory compliance and operational efficiency.

Ensuring Full-Surface Quality Assurance

Defects on the edges are much more frequent than people realize. Substrate misalignment, buildup of ink shifts in registration and edge fraying are common problems that usually start in the margins. If there aren’t dedicated inspection systems that cover all of the printing area, these issues could go unnoticed until discovered later in the process of the process of converting or by the final customer. Edge-to-edge inspections ensure that no part of the printed material, even the edges, is omitted from inspection. This is crucial in industries such as pharmaceuticals, food packaging and security printing where even a tiny error could render an item unsafe or incompatible.

Protecting Brand Image and Regulatory Compliance

A consistent print quality across the entire internet assures that each package label, package, or printed product is in accordance with the design and message intended. Incorrect edges, such as incomplete logos, insufficient barcodes, or off-color zones can affect the reputation of a company or cause a shipment to be rejected. In the realm of regulated industries like food-grade or medical packaging defects in the edges that are not detected can lead to recalls, violations of regulations or legal action. Edge-to-edge inspection can help mitigate the risk by providing full-width security.

Minimizing Waste and Production Downtime

Edge defects that are not detected can travel throughout the entire production process before being discovered and causing huge amounts of scrap material. This causes the waste of material, but also causes the amount of rework required and slows down production. Edge-to-edge inspection systems detect problems when they first appear, which allows to take quick corrective steps. No matter if the issue is a web guide that is not aligned properly or damaged print head or a poor tension management, early identification helps reduce the amount of waste and time spent.

Enabling High-Speed, High-Precision Production

Printing presses of the present, particularly in large web-sized environments, work at high speeds, with tight tolerances. These conditions require exact control and monitoring across the entire width of the web. Edge-to-edge inspection facilitates the production process at high speed, while preserving quality and consistency at all times. It also allows print companies to tackle complicated and large-volume projects confidently, knowing that they have complete defects detection capabilities built into their.

Supporting Digital Workflows and Traceability

Inspection systems today are typically coupled with digital quality control platforms that allow for the automatic recording of defects analytics, roll mapping. Through edge-to-edge inspection, businesses have complete traceability of the location and time an issue occurred, as well as whether it occurred close to the edges or in the center. This information aids in the analysis of root causes in addition to customer reporting and ongoing process improvement initiatives.

Key Differences Between Narrow and Wide Web Inspection Systems

Here’s a clear comparison chart outlining the differences between narrow and wide web inspection systems.

| Aspect | Narrow Web Inspection Systems | Wide Web Inspection Systems |

| Web Width | Typically 30″ (760 mm) | Usually > 30 inches (760 mm) typically as long as several meters |

| Typical Applications | Labels Security prints Pharmaceutical packaging, pharmaceutical labels | Paper, flexible packaging film, large-format printing |

| Camera Configuration | Single high-resolution camera, or dual-camera configurations | Multiple line scan cameras synchronized for complete coverage of the web |

| Edge-to-Edge Monitoring | Easier due to narrower span; simpler tracking | Needs sophisticated stitching algorithms and precise alignment |

| Lighting Requirements | Localized LED lighting | Wide-area, uniform LED or fiber-optic lighting |

| Inspection Focus | Small defect detection (e.g., missing dots, misregistration) | Broader defect types (e.g., wrinkles, streaks, print voids) |

| Data Processing Load | Volume of image data reduced and faster localized analysis | Large volume of data; requires the most powerful capabilities for real-time processing |

| Speed Handling | High speed to moderate speeds | High-speed compatible, but requires a robust synchronization |

| System Complexity | Compact, easy to install and maintain. | More intricate integration with unwinder, rewinder and cutting lines |

| Cost | Operating and initial costs | Greater investment as a result of technological demands and scale |

| Integration with web guides | Simple edge tracking integration | Multi-point feedback with advanced technology and tension control |

| Maintenance Needs | Lower; fewer components | More cameras; higher lighting and calibration points |

Key Technologies in Edge-to-Edge Printing Inspection Systems for Narrow and Wide Webs

1. High-Resolution Line-Scan and Area Cameras

The core of print inspection system, is hardware for imaging. Edge-to-edge inspection systems depend heavily on high-resolution line scanner cameras that provide continuous, live monitoring. These cameras take pictures line-by-line at extremely high speed, which makes them perfect for long-length substrates moving. For web applications with narrow widths that require fine details such as microtext or barcodes need to be scrutinized area scanners are also employed to concentrate on specific areas typically near the edges where imperfections such as print voids, or edges that are misaligned.

In wide web applications, several cameras are placed across the the substrate, giving total coverage. It is essential to ensure seamless edge-to-edge image, free of any blind spots or data overlapping issues.

2. Adaptive Edge Tracking Algorithms

One of the most difficult tasks in edge inspection is keeping the same alignment throughout web movement or drift in the lateral direction. Modern edge inspection systems use an adaptive edge tracking algorithm which detect the position of the substrate in real time and dynamically adjust the view field. This allows the system to constantly keep track of both edges even if the web moves in a slight manner during high-speed runs.

These algorithms also are capable of compensating for deformation of the substrate or minor changes in width of the material which is especially beneficial for stretchable or flexible packaging materials.

3. Uniform, Multi-Angle LED Illumination

To identify defects along the edges efficiently the use of uniform, glare-free lighting is crucial. Edge inspection systems usually utilize high-intensity and diffused LED lighting that is arranged at different angles to reduce reflection and shadowing. For narrow-web systems, focusing lighting helps to see bars and fine text and broad web applications require uniform lighting throughout the length to avoid hotspots and dim zones, particularly at the edges.

The use of color-correct lighting can also be used to identify chromatic variations as well as subtle inconsistencies in printing that could only be apparent under certain lighting conditions.

4. Real-Time Image Processing and Defect Classification

Real-time processing is vital in detecting and separating the appearance of edge defects. Advanced 100% printing inspection systems utilize powerful GPUs and processors to run machine-vision algorithms that are capable of identifying defects like color streaks, printing splatters, ink spills, missing print or die-cut alignment.

Advanced platforms incorporate machine learning models that have been trained using the historical data on defects to improve accuracy in classification and minimize false positives. These AI-enhanced systems are able to discern the difference between non-critical and critical flaws based on specific contexts, like the area of origin (edge or. middle) or the type of product.

5. Multi-Zone Zoom and Inspection Flexibility

For situations where different regions of the substrate need different inspection requirements, like logos of brands near the center and alignment marks close to the edges–modern systems offer multi-zone zooming capabilities. This lets users apply higher magnification or setting of sensitivity at edges of the web while allowing for greater coverage across central zones.

This flexibility is especially useful for hybrid inspection tasks that require small-sized webs, in which compliance-related features can be printed close to the edges.

6. Cloud Connectivity and Data Analytics

Many of the latest edge-to-edge inspection platforms provide cloud connectivity for remote monitoring and long-term analysis of data. This allows manufacturers to analyze patterns in quality, connect the types of defects with the settings of their machines or materials and continuously refine their processes. For industries with stringent traceability standards, digital records of the edge-to-edge inspection results are vital documentation to audits and customer assurance.

Integration of Edge-to-Edge Printing Inspection Systems with Web Handling Systems

Edge-to-edge printing inspection systems are designed to monitor the full width of a web to identify flaws, such as misregistration, ink, smudging or damaged substrates, or the absence of print. To ensure assurance of the print quality, this data needs to be immediately actionable. This is why integration with web handling systems, including web guides, tension control units, rewinders, splice detection modules, becomes essential. If these systems are integrated they can not only identify issues, but also cause mechanical or process-related responses to prevent further problems and ensure the integrity of production.

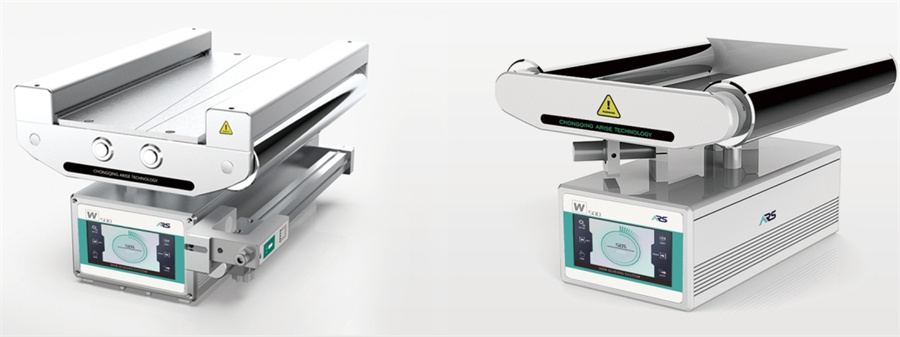

1. Closed-Loop Feedback Between Inspection and Web Guides

The main benefit of integrating is the development of a closed-loop feedback mechanism between the camera used for inspection and web guide systems. When the edge-to-edge inspection system detects lateral deviation or printing that is skewed near the edges of the web and edges, it will send correctional messages to actuators for the web’s guide. This will ensure that the substrate remains in the correct alignment, regardless of the speed of the machine or tension change. When it comes to high-precision work such as label printing or security packaging where millimeter-sized shifts count this feedback loop significantly reduces the amount of waste material and time.

2. Tension Control and Substrate Stability

Edge defects are usually caused by inadequate tension control, especially in wide-web applications that use material that is thin, stretchable or. When inspection systems find frequent flaws around the edges, such as tearing, wrinkling or smearing — this information is transmitted to the tension control module. The system then adjusts the web tension control automatically to help stabilize the substrate. This is particularly useful in applications that require fragile foils, films or multilayer laminates in which a constant tension is essential for print quality and edge quality.

3. Real-Time Defect Handling with Rewinders and Marking Units

Integration also allows quick intervention when defects are discovered. For example, if a edge-to-edge inspection tool detects a serious flaw in the web’s margin, such like a broken barcode, or an unfinished print, the system could activate a marker or an inkjet printer to highlight the flaw. It can also work with the rewinder’s controls in order to reduce or even stop the machine permitting the operator to locate and then remove the damaged area.

In fully automated settings, this communication can also allow automated roll mapping. Defects that are discovered across the web’s width are recorded using precise location data. This can then be utilized by downstream slitting or rewinding equipments to eliminate the areas that are defective, without stopping the entire production process.

4. Splice Detection and Synchronization

In the process of rolling to roll, splices are common and should be controlled with care. Edge-to-edge inspection systems, if combined with splice detection modules are able to synchronize inspection areas with the splice location. This helps to avoid false defect alarms and ensures that inspections are resumed with precision after the splice zone has passed. This integration level ensures constant quality assurance, without the intervention of an operator.

5. Data Sharing for Predictive Maintenance

The combination of web handling and inspection systems also facilitates maintenance that is predictive. When patterns of defect are linked with web behaviour–such as frequent misalignments near an edge or the progressive movement of a web, these indications could indicate wear and tear or deviations in the calibration of web guides and rollers. This allows for proactive intervention before the system fails, thereby increasing availability and decreasing unexpected stops.

6. Enabling Smart Factory Operations

In the Industry 4.0 environments integrated systems share information through a central digital platform. Edge-to-edge data for inspection can be displayed along with Web tension measurements, roller speed as well as guide-position logs. This gives an overview of the whole process. Operators can observe how web handling changes impact the quality of print around the edges, and then make adjustments from a distance. Integration also allows remote diagnostics, automated defect reports and live quality dashboards for production managers.

Future Trends in Edge-to-edge Printing Inspection in Narrow and Wide Webs

Edge-to-edge printing inspection has become an essential tool for quality assurance for both wide and narrow web print environments. As the speed of production increases and the demands of customers for flawless products grow and the future of the web inspection systems for printing operations is being determined by the advancements of artificial intelligence and connectivity and sensor technology.

1. AI-Driven Defect Classification

The most revolutionary developments is the integration of machine learning and artificial intelligence in edge-to-edge inspection methods. Instead of relying solely on rigid rules-based systems in the near future, printing inspection systems will utilize AI to study images and automatically categorize the severity and type of defects. This decreases false alarms and allows the system to gain knowledge from the pattern of defects that are repeated which improves the accuracy of its algorithms over time. For lines with wide webs, especially when multiple types of defects could coexist across the line, smart sorting improves the ability to make decisions and take corrective actions.

2. Real-Time Edge Behavior Analysis

In both wide and narrow webs, the edges can be among the most susceptible to discoloration and damage. The future inspection tools will feature edge behavior analysis in real time, connecting print quality near the edges to web dynamics like curl, flutter and tension fluctuations. This will enable proactive adjustments via connected web tension control or guiding units prior to the appearance of defects, bringing an era of quality control predictive.

3. High Resolution with Faster Processing

New sensor technologies are creating greater resolution line-scan and surface-scan cameras that be able to cover the entire width of the wide web at speedy speeds, without losing image quality. When combined with edge-to-edge illumination and super-fast image processing (such such as FPGA as well as GPU-based systems) These systems are able to increase production speed as well as detecting micro-defects within the margins of web pages.

4. Modular and Scalable Architectures

Edge-to-edge inspection systems in the future are moving towards modularity. In the case of narrow web configurations users can extend the basic system with the addition of lighting or cameras to cater to specific needs. In wide web-based applications, multi-camera arrays that are scalable can be configured to cover different areas and widths, which will allow the flexibility to adapt to different jobs or substrates without the need to redesign the entire system.

5. Enhanced Support for Sustainable Printing

As the industry of packaging shifts towards thinner, recyclable and bio-based materials, which are more susceptible to defects and deformations at the edges inspection systems have to evolve to adapt. The future technologies will incorporate intelligent algorithms and lighting systems that adjust for variations in reflection, transparency and behaviour near edges of the web. This will make quality control much more reliable even with environmentally-friendly materials that are difficult to work with.

6. Compact Edge Inspection for Digital and Hybrid Presses

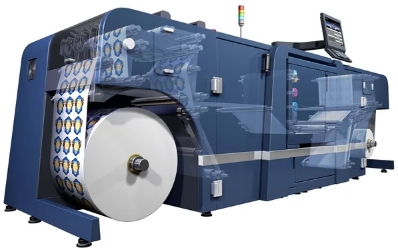

To cater to the increasing demand for hybrid and digital printing that typically involves quick changeovers and short runs Future inspection systems will feature compact designs that can be positioned directly on the output of the press. They will offer live edge monitors, barcode verification and registration checks that are in line with the speed and flexibility that workflows in digital require.

Final Thoughts

As consumer expectations and regulatory demands increase, edge-to-edge printing inspection has become essential for both wide and narrow web printing systems. Whether for intricate pharmaceutical labels or large packaging formats, investing in sophisticated printing inspection systems ensures that each millimeter of printed material is in compliance with the highest standards right from one edge to the other.