The Vital Role of Print Inspection Systems in Digital Label Printing

The digital label printing industry is experiencing rapid growth due to the demand for premium, custom labels and short-run production. Since the market is becoming more competitive, ensuring perfect print quality is vital to branding and customer satisfaction. This is where print inspection systems play an important role, improving the quality control process and cutting down costly errors in digital label printing.

Table of Contents

Challenges in Digital Label Print Inspection

This chart gives a thorough overview of the multifaceted challenges in print inspection for digital label printing, along with the operational implications.

| Challenge | Description | Impact |

| High-Speed Inspection Requirements | Inspecting thousands of labels each minute with no missing problems. | Potential for undetected flaws or system slowdowns leading to production bottlenecks. |

| Variable Data Verification | Verifying each barcode’s unique serial number, or even text in detail. | Incorrect data could result in regulatory infringement and customer distrust. |

| Substrate and Finish Diversity | Conducting inspections across transparent, shiny, metallic and smooth surfaces. | Inconsistent detection accuracy, and possible mistakes in interpreting defects on complex materials. |

| Detection of Subtle Visual Defects | Recognizing low-contrast smudges, color shifts or micro-misalignments. | Quality issues can be overlooked, leading to rejection of shipments or the need for reprints. |

| Lighting and Imaging Challenges | Adjusting for shadows, glare or transparency during inspection. | Visual distortion can affect the ability to detect defects, which can lead to false positives as well as negatives. |

| Data Integration and Workflow Sync | Uninterrupted connectivity to digital presses, databases and even rejection devices. | Incorrect alignment can cause delays in inspections, or permit incorrect labels to go unnoticed. |

| False Positives and Tolerances | The balance of sensitivity is important to avoid flagging flaws that aren’t critical. | Production delays or cost due to unneeded rejections. |

| Cost of Advanced Inspection Systems | Maintenance and capital investment are high. of advanced equipment. | Accessibility is limited for smaller businesses and could hinder the adoption process. |

| Operator Training and Usability | Ensuring that staff are able to set up and monitor the inspection equipment efficiently. | Unresponsiveness or misconfigurations could lead to low inspection precision. |

Why Print Inspection Systems are Important in Digital Label Printing

- Ensuring Consistent Quality Across Short Runs: Contrary to traditional printing methods labels, digital printing usually requires short runs, and frequently designs or data modifications. This increases the chance of errors such as misregistration or the shifting of colors, smudges or missing components. Print inspection systems examine output in real-time and immediately detect any defects to reduce waste and unnecessary the need for reprints.

- Verifying Variable Data Accuracy: One of the biggest benefits of digital printing is the capacity to print unique barcodes serial numbers, barcodes or batch information on each label. Print inspection systems ensure that the variable information is precise and reflects the content intended, which ensures that the label is in compliance with regulations and has traceability. In the absence of this verification, mistakes in variable data could result in costly recalls and loss of trust among consumers.

- Reducing Waste and Operational Costs: In spotting defects before production, the systems of print inspection can stop large quantities of label that are not in good condition from being printed. The early detection of defects saves material as well as time and labor that is required for reprints or recalls. In time, the reduction in waste is a benefit to both sustainable operations and environmental savings.

- Enhancing Customer Satisfaction and Brand Integrity:Labels are typically one of the initial points of contact between a brand and its purchaser. Incorrect labels can affect the perception of a brand and also affect consumer confidence. Print inspection systems aid in maintaining the integrity of a brand by making sure that only the most flawless labels are released to the market, further demonstrating a company’s dedication to high-quality.

- Assisting Compliance with Industry Standards: Numerous industries, like food, pharmaceuticals and cosmetics, are subject to strict labeling requirements. Print inspection systems aid manufacturers to meet these standards by ensuring the accuracy of labels and readability, which is crucial for the safety of the product as well as regulatory audits.

- Facilitating Automation and Workflow Efficiency: Advanced automated web inspection systems for printing operations are integrated perfectly with digital presses as well as workflows in production. This integration facilitates automated process for rejecting and detecting defects eliminating the requirement for manual inspection, permitting operators to concentrate on other important tasks. The result is that the efficiency of production overall improves.

Key Capabilities of Print Inspection Systems in Digital Label Printing

As digital printing continues to grow in popularity in industries that demand speed and flexibility the importance of integrating advanced printing inspection systems into production lines is more important than ever. These print inspection systems guarantee that each label produced meets the high quality and standards of regulatory compliance.

1. Real-Time, 100% Inspection

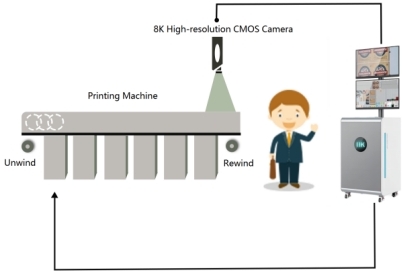

One of the most significant features of modern 100% printing inspection systems is the ability to provide real-time, 100% inspection of each label produced by the line of production. In contrast to manually sampling methods, this guarantees every label is not missed regardless of size or speed of printing. High-speed cameras scan every label frame-by-frame and detect even the smallest deviations from the expected outputs.

2. Detection of a Wide Range of Defects

Print inspection systems are able to detect a wide range of printing defects.

This chart highlights the key defects that print inspection systems can help identify to ensure high-quality digital label printing.

| Defect Type | Description |

| Color Variation | Inconsistent color shades or improper reproduction of colors compared to what was originally designed. |

| Misregistration | Incorrect alignment of different colors or elements can result in the blurred images or doubled. |

| Smudges and Streaks | Streaks or marks that are not wanted caused by smearing ink or dirty printing equipment. |

| Missing Elements | Design elements or text are missing due to ink supply issues or printing mistakes. |

| Ghosting | Duplicate images appearing in the vicinity of the original print, usually caused by printing problems. |

| Banding | Horizontal and vertical lines result from uneven distribution of ink or mechanical issues. |

| Blurred Text/Images | The loss of clarity in graphics or text because of lack of focus or movement during printing. |

| Variable Data Errors | Unusual or incorrect data, like serial numbers, barcodes as well as batch numbers. |

| Surface Defects | Physical damage to labels, such as scratches, dents or bubbles that alter the appearance or performance. |

| Barcode Errors | Incorrect barcodes or misprints can lead to problems with scanning or compliance. |

This extensive coverage reduces the possibility of deficient labels being sold on the market.

3. Verification of Variable Data

Digital printing is often utilized for serialized or personalized labels, the capability to validate variable information is vital. Advanced systems can compare each printed label against a digital template, validating elements such as unique barcodes, serial numbers, and product information–ensuring every unit is accurate and traceable.

4. High-Speed Performance Without Downtime

Inspection systems of the present are constructed to cope with the speed of digital presses. By using parallel processing and sophisticated algorithms, they can examine thousands of labels every minute without slowing down production which is able to maintain productivity and high-quality.

5. Integration with Workflow and Rejection Mechanisms

Modern systems are able to seamlessly integrate with digital printing workflows as well as finishing equipment. If a defect is discovered the system can activate the rejection mechanism, locate the label that is defective and report the issue. This is not just a way to maintain the integrity of the product, but also cuts down on wasted time and rework.

6. Adaptability to Different Materials and Finishes

Digital label printing usually requires a range of substrates, from film and paper to foil and the textured materials. Print inspection systems come with flexible lighting, optics and software calibration that allows you to examine a variety of surfaces regardless of reflectivity or transparency.

7. Detailed Reporting and Analytics

Another crucial ability is the creation of audit reports, as well as analytics. The logs of data provide important insight into the trends in defects along with production consistency and the performance of machines. As time passes, this data aids continuous improvement as well as predictive maintenance and improved process control.

8. User-Friendly Interface and Customization

The ease of use is vital in the fast-paced printing environment. Modern inspection systems have intuitive interfaces that permit users to swiftly alter parameters, establish tolerances for defects, and view the real-time feedback. Furthermore, the flexibility of rules ensures that the system is in line with specifications of the product or industry.

Best Practices for Implementing Digital Label Print Inspection System

This chart is a simple guide for the successful implementation of printing inspection systems. It will help you to ensure the reliability and value from your digital label print inspection investment.

| Best Practice | Implementation Insight |

| Define Inspection Objectives Clearly | Find out if you are trying to find visual flaws or to verify the validity of data or both. |

| Choose Technology Based on Substrate | Choose the right cameras and lighting to the material being labeled (e.g. reflective or transparent). |

| Connect to Prepress and Workflow Systems | Make sure that there is a seamless connection to ensure seamless communication RIP and database systems, as well as presses, and inspection systems. |

| Set Realistic Tolerance Thresholds | Avoid over-sensitivity which leads to false positives as well as unnecessary waste. |

| Conduct Regular Calibration | Make sure to check the system frequently to ensure consistency and accuracy in detection. |

| Train Operators Thoroughly | Give structured instruction on setting up as well as troubleshooting and interpretation of the results. |

| Beginning with the Pilot Runs | Check the system through controlled tests to refine the configuration prior to deploying the system fully. |

| Enable Real-Time Monitoring and Alerts | Utilize alarms and dashboards to spot issues quickly and minimize the amount of downtime. |

| Log and Analyze Inspection Data | Save historical defect records to improve quality and for analysis of root causes. |

| Make sure you work with a Reputable Vendor | Select a provider with a robust support, regular updates and capabilities for customization. |

Future Trends in Print Inspection Systems for Digital Label Printing

As the technology of digital label printing continues to develop and become more sophisticated, the need for smarter, more efficient, and faster printing inspection systems is increasing quickly. These systems are essential to ensure consistent print quality, especially in high-speed, short-run and variable data printing environments. With advances in machine vision, AI, and automation, the world of print inspection is is poised for transformation.

- Integration of Artificial Intelligence and Machine Learning: The use of AI in inspection is becoming more popular. Machine learning algorithms can be trained to detect difficult defects, adjust to different substrate types, and decrease false positives. They will not just find flaws but will also identify possible issues prior to them impacting production.

- Enhanced Data Analytics and Predictive Maintenance: The future of inspection for printing is not only about defect detection but data-driven decision-making. Advanced systems will provide predictive analytics that will help you identify patterns in defects, analyze the performance of the machine, and suggest maintenance schedules that will prevent the possibility of downtime.

- Cloud-Based Remote Monitoring and Reporting: In the context in Industry 4.0, cloud-enabled inspection systems will allow inspectors as well as quality assurance teams access to inspection reports, live monitoring and historical data from any place. This will improve the responsiveness of inspections and help with central quality management.

- Real-Time Closed-Loop Feedback Systems: Print inspection systems that are next-gen will not just detect flaws but also rectify them immediately. Through direct communication with finishing equipment and digital presses they can automatically adjust the parameters of print increasing efficiency and decreasing the amount of waste.

- Greater Focus on Sustainability: With a growing focus on the environment, inspection systems are designed to minimize the amount of waste that is generated. Intelligent systems that reduce unnecessary rejections and reprints help to create more sustainable printing practices.

- Modular and Scalable Architectures: To accommodate a variety of labels and press format, future inspection systems will feature modular designs. This will allow users to expand systems in accordance with production requirements and to upgrade specific components (e.g. cameras and lighting) without a complete overhaul of the system.

- Intelligent Variable Data Verification: When variable-data printing gets more complicated Inspection systems will come with more powerful data verification tools. These include OCR (optical character recognition) barcode validation and database matching, all at high speed with very little errors.

- Enhanced Imaging Technology: Future systems will integrate ultra-high-resolution cameras and multispectral imaging to detect even the subtlest imperfections on diverse substrates, including metallic, transparent, and textured materials.

Final Thoughts

In the high competitive market of digital label printing, an effective print inspection system is essential. It ensures high-quality printing, reduces costs, and helps protect brand reputation. As technology advance, the systems will get even smarter and more integrated, allowing printers to produce flawless labels at a higher effectiveness.