How to Improve the Energy Efficiency of Web Guiding Systems

With the increasing focus on sustainability and cost-savings in operations, the energy efficiency in web guiding systems has been recognized as a major aspect for manufacturers. This article explores the importance of energy efficiency, as well as principal strategies, methods, and innovations that aid in improving the energy efficiency in web guide systems.

Table of Contents

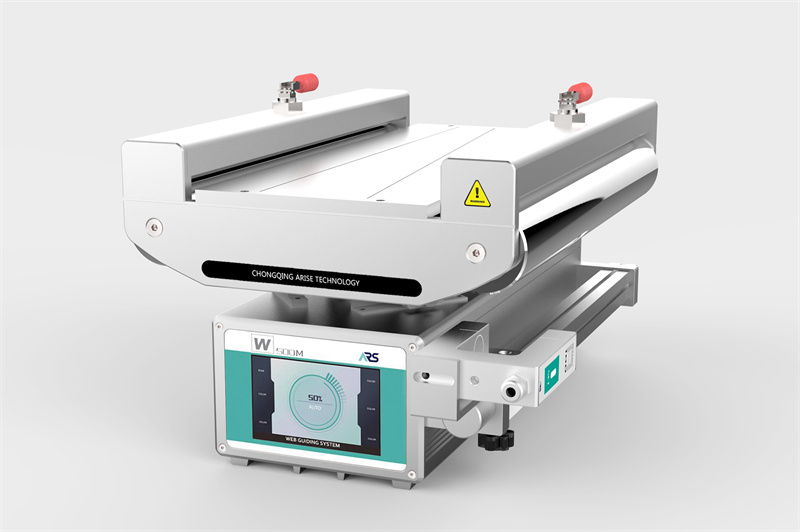

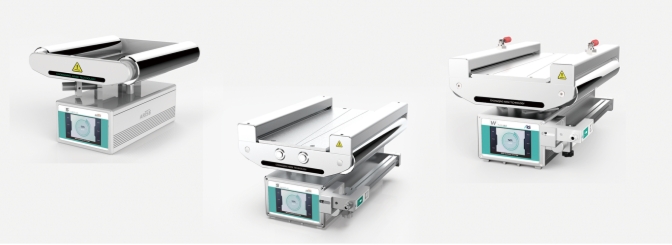

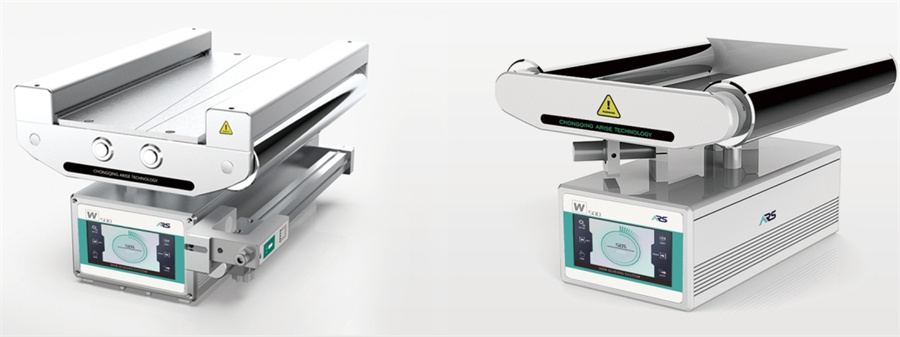

Understanding Web Guiding Systems

Web guide systems can be used to control the lateral movement of a web that is moving to ensure it is straight throughout the entire production process. They typically comprise actuators, sensors, controllers and the guiding mechanism. Although the main goal is accuracy, the energy usage can be significant, particularly when large-scale or high-speed operations are involved.

Sources of Energy Consumption in Web Guiding System

| Source | Description | Typical Energy Impact |

| Actuators (Motors/Drives) | Control the movement to ensure web correction. It is possible to operate constantly in a variety of systems. | High |

| Control Electronics | process sensor signal signals, and control motor functions. Always active. | Medium |

| Sensors (Edge/Line Detectors) | Find out the location of the web. Generally not very powerful, but always active. | Low |

| Power Supply/Conversion Losses | Inefficiencies in the conversion of input power into usable voltage levels. | Medium |

| Idle Power Draw | The energy consumed during idle or standby periods without closing down. | Medium |

| Ice Systems (if there is any) | Some high-performance systems require active cooling (e.g., fans). | Low to Medium |

| Mechanical Friction | Not electrical, but is a contributing factor indirectly through increased demands on motors. | Indirect Energy Cost |

Why Energy Efficiency Matters in Web Guiding Systems

Reducing Operational Costs Through Energy Savings

Web guiding systems that use energy efficiently assist manufacturers to cut back on one of their largest costs – electricity. Traditional systems typically operate motors and actuators indefinitely regardless of whether or not correction is required. This is a constant process that results in over-use of power. However, the latest web guiding technology that is equipped with intelligent sensor and adaptive control function solely when aligning corrections are needed. In removing excessive energy consumption businesses can cut down on their power bills while not any loss of efficiency.

Enhancing System Performance and Longevity

Effective systems aren’t just efficient in reducing energy use, they also enhance overall performance of the system. web guiding systems that rely on sophisticated motor controls and optimized motor functions are less subject to mechanical strain, which can reduce wear and wear and tear. In turn, parts such as motors and actuators have longer lives, while maintenance time intervals get prolonged. This smoother operation also increases the stability of the process, resulting in greater product quality and fewer interruptions in production.

Supporting Sustainability and Regulatory Compliance

With the increasing environmental regulations and reduction in carbon goals across all sectors and sectors, energy efficiency is tightly dependent on a company’s capacity to comply with sustainability standards. Web guide control systems that use less energy contribute to less carbon emissions across the entire facility. This is not just beneficial for the environment, but also boosts the company’s reputation with regard to sustainability certifications, audits and reporting on corporate social responsibility. If a manufacturer is looking to be in line with ESG (Environmental and Social and Governance) objectives, converting to energy-efficient guide systems is an important decision.

Enabling Smarter Manufacturing Practices

Web guiding systems that are energy-efficient typically have sophisticated monitoring and control capabilities. These features allow operators to monitor their energy usage in real-time, spot inefficiencies and enhance efficiency. Integration with automation systems across the entire plant as well as energy management software can lead to automatic maintenance, predictive load adjustments, as well as improvement of processes that are based on data. Control of this level is in line the industry 4.0 initiatives, in which intelligent interconnected equipment is the basis of a productive production.

Delivering a Competitive Advantage

In a competitive market each ounce of efficiency is important. Energy-efficient web guiding equipment not only reduces operating costs and promotes sustainable branding, but it also helps reduce manufacturing errors and downtime. This translates into shorter delivery times, improved product quality, and greater satisfaction with customers. Manufacturers that focus on efficiency in their web guide systems are ahead of their competitors in terms of the cost of their products and their environmental responsibility.

Key Strategies to Improve Energy Efficiency in Web Guiding Systems

Web guide systems function continuously in a wide range of applications, enhancing their energy efficiency, which provides significant opportunities to cut down on the overall energy consumption, operating expenses and environmental impact.

1. Optimize Sensor and Control Integration

A highly powerful methods is to upgrade to advanced sensors and control systems. Traditional web guiding systems usually perform frequent corrections that are based on fixed timing regardless of the actual requirements. Modern systems utilize high-resolution sensors, paired with sophisticated control algorithms that only adjust when needed. This reduces the activity of actuators and consequently reduces energy consumption. Implementing the techniques of predictive and adaptive control can further cut down on energy usage because they stabilize the entire system, and stopping overcorrection.

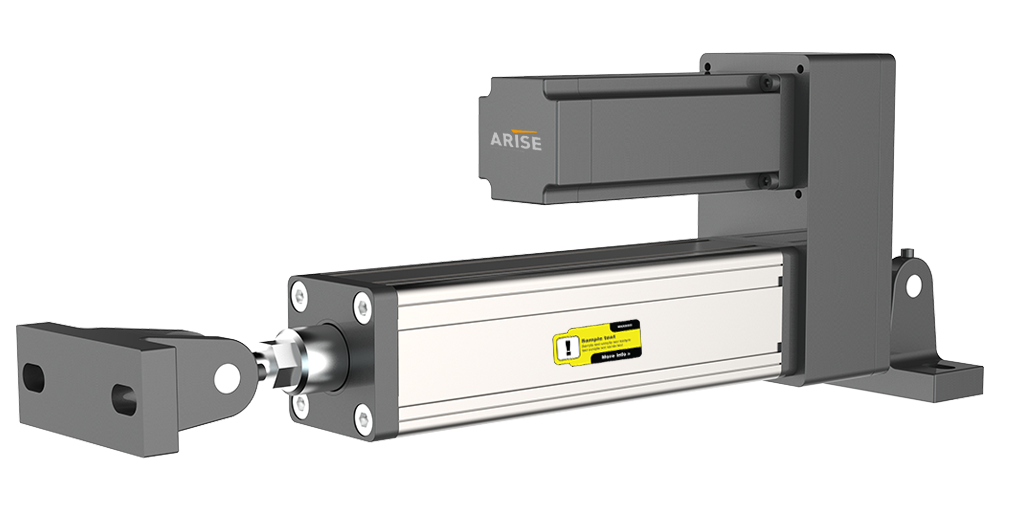

2. Upgrade to High-Efficiency Actuators and Drives

Actuators are the mainstays of web guiding systems, making up the majority of energy required. The replacement of old inefficient actuators with motors that are brushless DC motors, or even energy optimized servomotors can significantly reduce power consumption and provide greater quality and precision. Additionally, using energy-regenerative drives permits the use and re-use of excess energy, particularly during deceleration, instead of releasing it into heat.

3. Use Lightweight and Low-Friction Mechanical Components

Efficiency in energy isn’t just about electronic controls and electronics, it’s also about mechanical. Systems that are made of lightweight moving parts and low-friction guiding assemblies require less effort in order to function, which leads to less energy input. Re-engineering the frame’s design as well as switching materials that have higher energy transfer capabilities can increase the effectiveness of the whole guide system.

4. Implement Real-Time Monitoring and Energy Management

The integration of web guiding systems into the digital infrastructure of a factory allows for continuous energy monitoring and analysis of usage. These data can help identify patterns of energy consumption or excessive use that may not be evident during routine operations. Facilities can make use of this information to tweak the settings of control, spot inefficiencies, and plan maintenance in order to prevent losses of energy because of wear or degrading of the system.

5. Minimize Unnecessary Idle Operation

In some instances, web guiding systems can continue to operate even when production has stopped or alignment corrections aren’t required. Automatic shutdown or energy-saving features can drastically cut power consumption during idle periods. Systems that detect downtime or absence and then respond by turning down equipment can result in significant energy savings over time.

6. Ensure Proper System Calibration and Maintenance

A misaligned or poorly calibrated web guiding system could have to make numerous unnecessary adjustments which consume more energy than is needed. Regular maintenance in a web guiding system, which includes alignment checks and actuator calibration, ensures that the system operates efficiently. Cleaning sensors and keeping mechanical components in good shape can also help reduce energy loss due to slippage, friction or misdetection.

Future Trends in Energy-Efficient Web Guiding Systems

Energy-efficient web guides is being formed by cutting-edge technology, intelligent control, as well as the larger objectives of industry 4.0 and sustainable development.

1. Integration of Artificial Intelligence for Predictive Efficiency

A major and revolutionary developments in energy-efficient web guide systems is the incorporation using Artificial Intelligence (AI) as well as machine-learning. These systems allow them to predict the behavior of web pages based on the conditions in real-time, like tension, speed, and edge variation. In anticipating the requirement to correct instead of continuously reacting in response, these AI systems drastically reduce the activity of actuators, leading to lower energy use and a smoother operating. As these algorithms become refined they can allow for highly adaptive guiding, which reduces energy consumption without sacrificing precision.

2. Ultra-Low-Power Sensors and Edge Computing

The next generation of web guiding systems is likely to include ultra-low power sensors equipped with advanced computing features. These sensors will not just use less energy, but they will also handle data locally, which will reduce the need to communicate between central controls. This decentralized intelligence enables quicker responses and decreases the energy consumption that is associated with processing and transmission of data. In addition these systems could allow self-calibration and failure detection. This will help in increasing efficiency of energy through optimized maintenance cycles.

3. Regenerative Actuator Technology

Actuators are one of the most energy-intensive parts of a web guide system. The next generation of actuators will likely feature regenerative capabilities–capturing kinetic energy during deceleration or load release and converting it into usable electrical energy. The energy gathered can be re-incorporated to the system, decreasing the overall power consumption and boosting the sustainability of. The advancements in the design of motors like the use for high-efficiency brushesless motors as well as intelligent drive systems, could help to reduce energy consumption and improved thermal management.

4. Adaptive Power Management Systems

Another important trend in the near future is the use of adaptive power management. Smart web guiding systems will be equipped with power regulation features that will adjust energy consumption according to speed, workload and production cycle demands. They will be able to enter low-power state during periods of idle or will automatically shut down any subsystems that are not operating. By adapting the energy consumption to the operational demands, companies are able to further cut down on unnecessary energy consumption and boost the overall efficiency of the plant.

5. Digital Twin Technology for Energy Optimization

Digital twin technology, which is a virtual replica of physical systems — will play a increasing role in improving the efficiency of energy-efficient web based guiding systems. Digital twins can simulate real-time operations, and help find areas where energy savings can be achieved without impacting the performance. Through the simulation of various manufacturing scenarios, technicians are able to adjust controls algorithms and mechanical configurations to reduce the energy footprint. This proactive approach to energy management is in line with smart factory strategies and prescriptive maintenance practices.

6. Sustainability by Design

Future web guiding systems will increasingly be developed with a design-for-sustainability philosophy. This means not just making use of energy-efficient components, but also using recyclable materials, reducing mechanical friction and reducing impacts on the environment from production and the disposal. Energy efficiency will be integrated in every aspect of the system design including component selection, to the overall management of lifecycles.

Summary

The energy efficiency in web guiding systems is a requirement. Through the use of advanced components such as optimizing control logic and using advanced actuation technology manufacturers can dramatically reduce operational expenses while also promoting sustainable development. As the industry continues to emphasize green manufacturing, Energy-efficient web guide system will have a key contribution to shaping the future of manufacturing lines.