What Are The Key Components Of Web Guiding System

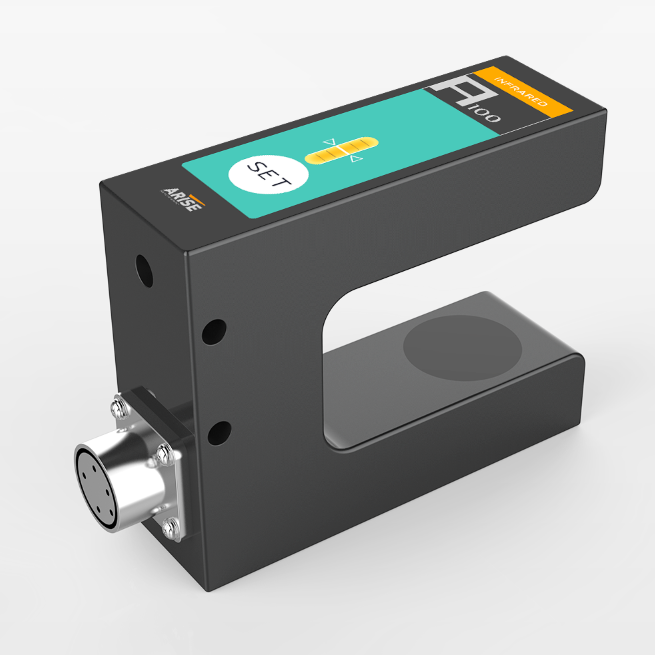

A web guiding system typically consists of a web guide sensor, a web guide controller, a web guide actuator, a human-machine interface, a power supply, a mechanical structure, communication interfaces, diagnostic and monitoring tools, and safety measures.

Web Tension Control Devices Of Web Guiding System

Web tension control is an important feature of web guiding systems because it guarantees correct tension in the moving web during production processes.

Load cells

Load cells are sensors that detect the force imparted to the web by the roller or other guiding devices and quantify the tension in the web. They transform tension force into an electrical signal that the controller uses to regulate tension.

Brakes

Brakes are mechanical or electromagnetic devices that apply controlled resistance to the web, hence regulating tension. Magnetic powder brakes can be applied to the web directly or via a tension control element such as a dancer roller or a pneumatic brake.

Clutches

Clutches are mechanical devices that deliver torque to manage the tension of the web. They enable for exact tension control by engaging and disengaging the web from the motor mechanism.

Dancer rollers

Dancer rollers are free-rotating rollers used to collect or release web tension. They move up and down in response to web tension and send feedback to the controller, which changes the tension accordingly.

Pneumatic or hydraulic cylinders

By altering the location of the guiding devices or rollers, pneumatic or hydraulic cylinders can be utilised to apply or release strain on the web. The controller regulates the tension in the web by controlling them.

Inverters or drives

Inverters or drives are used to control the speed of motors that drive the web guiding system. By adjusting the motor speed, the tension in the web can be controlled.

Controllers And Algorithms For Web Guiding System

PID (Proportional-Integral-Derivative) Controllers

PID controllers are widely used in web guiding systems to regulate web tension and position. They calculate the error between the desired web position or tension and the actual position or tension measured by the sensors. The controller then adjusts the guiding devices or rollers by generating control signals based on the proportional, integral, and derivative terms, which provide proportional, integral, and derivative actions to correct the error and maintain precise web alignment.

PLC (Programmable Logic Controller)

PLCs are web guide controllers that process sensor inputs, execute control logic, and generate control signals for guiding devices or rollers. PLCs are programmable and can be tailored to execute various control techniques, such as PID control, feed-forward control, and advanced control algorithms, based on the needs of the manufacturing process.

Feed-forward control

Feed-forward control is a mechanism for preventing web misalignment by anticipating changes in web tension or position based on known process variables. Feed-forward control algorithms predict web behaviour using mathematical models or empirical data and create control signals appropriately, enhancing the system’s responsiveness and accuracy.

Adaptive control

Adaptive control is a control approach that modifies the control settings based on the changing process conditions to maintain optimal performance. Adaptive control algorithms continuously update the control settings based on real-time sensor data, adjusting to changes in web properties, machine speed, and other process variables, assuring precise web directing even under changing conditions.

Fuzzy logic control

Fuzzy logic control is a control system that processes sensor inputs and generates control signals using fuzzy logic, which is a mathematical foundation for dealing with uncertainty. Fuzzy logic controllers can handle ambiguous or imprecise inputs and can be utilised in web directing systems where process variables are not well-defined or change over time.

Neural network control

Neural network control is a control approach that processes sensor inputs and generates control signals using artificial neural networks. Neural networks can learn from prior data and adapt to changing process conditions, making them suited for sophisticated nonlinear and dynamic web directing systems.

User Interface And Operator Controls Of Web Guiding System

A web guiding system’s user interface and operator controls are intended to provide a user-friendly and intuitive means for operators to interact with the system and monitor its performance.

HMI (Human-Machine Interface)

The graphical interface that allows operators to interact with the web guidance system is known as the HMI. It usually has a touchscreen display that gives visual input on the system’s status, such as web position, tension, and alarms. The HMI may also allow operators to alter control parameters and configure system settings, as well as set desired web position or tension.

Control panel

The control panel is a physical interface that allows operators to control the web guiding system using buttons, switches, and knobs. It may offer options for adjusting the guiding devices or rollers, establishing tension limits, beginning system calibration, and performing other manual control activities.

Remote control

Some web guiding systems may also provide remote control capabilities, allowing operators to engage with the system remotely using remote control devices or a remote access interface. Remote control can make it easier and more flexible to operate the system from multiple places within the production environment.

Alarms and notifications

Alarms and notifications may be included in the user interface to inform operators to any flaws or abnormalities in the web guiding system, such as web misalignment, tension deviations, or system faults. Alarms and notifications can assist operators in immediately identifying and addressing problems, maintaining the smooth and effective running of the system.

Data visualization and logging

Visual representations of real-time and historical data, such as web location, tension, and other process variables, may be provided by the user interface. Data visualisation can assist system operators in monitoring system performance, identifying trends, and making educated decisions. Data logging is also an option, allowing operators to analyse historical data for troubleshooting, analysis, and process optimisation.

System status and diagnostics

The user interface may display system status information such as system health, communication status, and diagnostics. Indicators, status messages, and diagnostic tools can all be used to provide operators with information about the system’s performance and health.

Help and documentation

To assist operators in properly managing and maintaining the web guiding system, the user interface may additionally include assistance and documentation features such as user manuals, online help, and troubleshooting guides.

Summary

The components of web guiding system collaborate to precisely align and direct online content during production processes, assuring high-quality output and efficient operation.