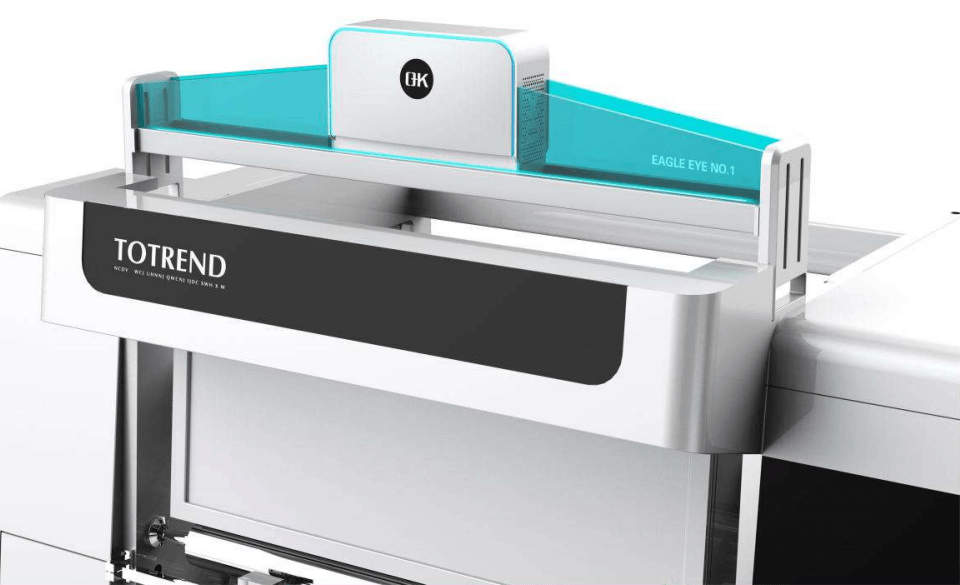

Key Functions of OK-8000 Type 100% Full-surface Print Inspection System

The O+K type 100% full-surface printing Inspection System combines advanced image processing and AI algorithms for efficient, precise, and reliable printing inspection across industries. It is designed for detecting defects such as scratches, stains, dents, damage, color variations, etc, widely used in industries of printing, lithium batteries, photovoltaics, packaging, tires, pharmaceuticals, textiles, glass, plastics, and metals.

Technical Parameters of 100% Full-surface Print Inspection System

| Subject | Parameter | Remark |

| Nominal lateral resolution | 0.15mm | Width1200mm |

| Nominal vertical resolution | 0.15mm | |

| Designed detection width | 10mm-1500mm | |

| Designed maximum speed | 450m/min | |

| Dot Defect detection accuracy | Defect Area>0.2mm² | Stains, Missing Prints, Foreign Objects, Insects |

| knife line detection accuracy | Defect Area>0.1m m*5mm | |

| Registration detection accuracy | Lateral>0.15 mm, Longitudinal> 0.25mm |