Sustainability in Printing Inspection

In the rapidly growing manufacturing industry, sustainability has become an essential aspect in every process from raw materials sourcing to final product delivery. Printing inspection which is a crucial quality control step in the packaging labeling, publication, and packaging industries, is no exception. It has traditionally relied on resource-intensive methods. With the advancements in technology and eco-friendly strategies, printing inspection has become more sustainable without compromising quality.

Table of Contents

The Environmental Impact of Traditional Printing Inspection

| Aspect | Environmental Impact |

| Material Waste | Paper and ink waste due defects that are detected late in the stage and Reprints. |

| Energy Consumption | Manual systems and those that are less efficient use more energy when they are used for long inspection cycles. |

| Chemical Usage | Reprints frequently and tests for setup make use of cleaning chemicals and solvents. |

| Emissions | More energy consumption and garbage disposal are the main factors that contribute to the increase in carbon dioxide and VOC emissions. |

| Resource Inefficiency | In systems that are not optimized, there is a high use of ink, water and other essential materials. |

| Manual Labor Dependence | Human errors during inspection cause undetected problems and a further loss in the downstream. |

| Lack of Data Optimization | The inability to collect data hinders improvement of processes and results in regular inefficiencies. |

Key Sustainable Innovations in Printing Inspection

These advancements are transforming how printing operations detect and address defects, leading not only to better print quality control but also significant reductions in waste, energy consumption and environmental impact.

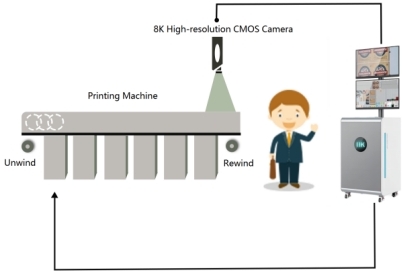

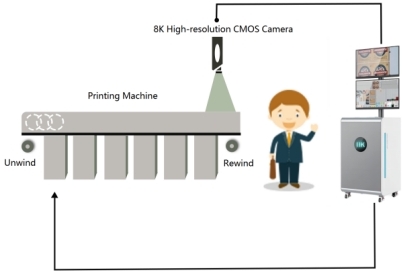

1. Intelligent Automation and Machine Vision

A major and revolutionary sustainable advancements in the field of print inspection has been the fusion of intelligent automation and machines-vision technology. These web inspection vision system during printing operations, make use of images sensors, high-speed cameras and artificial intelligence, to evaluate each printed item in real-time. This reduces dramatically the quantity of damaged prints by recognizing defects early in production. It also means lesser waste and a reduced requirement for reprints. This significantly cutting down on the use of resources.

In contrast to manual inspection, which can be time-consuming and susceptible to human mistakes Machine vision systems provide constant quality and efficiency. Also, these systems require less light and less operational cycles, which results in less consumption of energy. Through enhancing the accuracy and efficiency they can help with quality assurance and sustainability.

2. Cloud-Based Data Analytics for Waste Reduction

Advanced printing inspection systems rely on cloud connectivity to manage and analyze huge amounts of production data. Cloud-based platforms allow manufacturers to monitor trends in defects along with production efficiency and the use of materials over time and across machines. With this information operators can pinpoint the root of any recurring problems and take preventive steps to fix them.

This approach to analysis can help reduce waste in the system and unneeded downtime, which results in a better utilization of resources and increased energy efficiency. It also helps with proactive maintenance strategies that help minimize the risk of equipment failure and prolong the life of inspection equipment.

3. Sustainable Ink and Substrate Compatibility

Another significant improvement is the development of print inspection systems that are compatible with eco-friendly materials. As printers move to water-based or soy-based and UV-curable inks for reducing VOC emission, the inspection equipment have to adapt to the new chemicals. Modern technology for image processing and optical system effectively detect changes in non-traditional inks as well as biodegradable substrates. This allows green production without compromising precision.

This compatibility ensures that environmentally sustainable materials are included in the quality control process, encouraging circularity while reducing the need for toxic chemicals.

4. Modular and Energy-Efficient Designs

The sustainability of print inspection systems includes their physical design. Manufacturers are currently developing modular inspection units that can be upgraded and modified without having to replace whole systems. This helps reduce electronic waste and reduces the overall environmental cost of owning the unit. In addition, energy-efficient components like LED lighting and processors that consume less power are being used in systems of inspection in order to reduce operational energy usage.

These design enhancements will not only reduce emissions from inspections but also result in cost savings as well as the capacity to grow to allow for growth in the future.

5. Digital Twins and Simulation Technology

New technologies such as digital twins and simulations allow simulation-based testing of inspection workflows prior the implementation. The tools enable manufacturers to create scenarios for defect detection and optimize the settings for inspection and decrease the time spent on trial-and-error production processes, all without using up resources. Through reducing testing in real-world conditions digital twins save ink, substrates and machine time, while also which is in close alignment with sustainability targets.

Environmental and Economic Benefits of Sustainable Printing Inspection

Reduced Material Waste and Resource Consumption

One of the biggest environmental advantages of a sustainable print inspection is the substantial reduction in waste material. Traditional inspections typically involved post-process defect detection that led to a large number of wasted prints. Modern 100% printing inspection systems that are sustainable, supported by live monitoring in real-time as well as high-speed camera systems, detect mistakes immediately. This means fewer reprints and less waste of paper, ink or packaging supplies. As time passes, this can translate to more efficient use of resources and less stress on the supply chain of raw materials.

Lower Energy Usage and Emissions

New inspection devices are built using energy-efficient technology in the forefront of. Lighting systems that use LEDs, computerized controls and optimized data processing procedures all help reduce energy usage compared to manual or mechanical methods. Furthermore, as companies move to using eco-friendly inks such as UV-curable or water-based types and UV-curable ones, the emissions of VOCs (VOCs) are greatly decreased. This helps to create greener production environments and reduce the carbon footprint of printing processes.

Cost savings resulting from operational efficiency

Sustainable print inspection systems also provide an enormous economic benefit. Through identifying defects early during the printing process, they avoid financial losses that result from scrap materials, rework and production delays. The streamlining of processes improves productivity and provides more predictable timeframes for job completion. In high-volume environments even tiny gains in error detection could be a major source of reduction in operating expenses.

Equipment Longevity and Maintenance Optimization

Predictive maintenance is another characteristic of sustainable printing inspection systems. By incorporating sensors as well as analytics, they are able to detect wear or abnormalities before they lead to breakdowns. A proactive strategy for maintenance of equipment prolongs the life of equipment and decreases the necessity for costly repair or replacement in the event of an emergency. Less interruptions also translate into increased availability of equipment and higher productivity.

Competitive Advantage and Market Access

Businesses who invest in sustainable printing inspections will be better equipped to fulfill the requirements of eco concerned customers and regulators. Compliance with certifications is simpler to achieve with robust environmentally-friendly inspection procedures implemented. This can improve a business’ image, increase confidence with partners and provide access to emerging markets where sustainability is a major buying quality criterion.

Industry Standards and Certifications for Sustainable Printing Inspection

| Standard/Certification | Description | Relevance to Printing Inspection |

| ISO 14001 | The International Standard for Environmental Management Systems (EMS). | Inspires environmental stewardship when conducting inspections and activities. |

| FSC(r) (Forest Stewardship Council) | The certification is for paper that is responsibly sourced or wood items. | Make sure that the printed materials used for inspection are sustainable substrates. |

| ENERGY STAR(r) | Energy-efficient equipment certification. | It is applicable to energy-saving inspection equipment and their components. |

| RoHS (Restriction of Hazardous Substances) | EU directive restricting harmful materials in electronics. | Promoting the use of compliant and environmentally friendly components for inspection equipment. |

| EPEAT (Electronic Product Environmental Assessment Tool) | Global ecolabel for sustainable electronics. | Supports the choice of eco-friendly inspection equipment. |

| ISO 9001 | Standard for Quality management systems for quality management. | Improves efficiency and consistency of inspection by reducing time and effort. |

| Cradle to Cradle Certified(r) | Evaluates the safety of products, their circularity, sustainability and safety. | Important to ensure that inspected products are of high environmental quality. |

| GHG Protocol | The framework is designed to measure and regulating greenhouse emissions of greenhouse gases. | Aids in reducing emissions from inspections. |

Challenges and Future Trends in Sustainable Printing Inspection

| Challenges | Description | Future Trends |

| High Initial Investment | Innovative sustainable inspection techniques usually require a significant amount of capital upfront. | More affordable and more scalable solutions to make green inspection more accessible. |

| Integration with Existing Systems | The difficulty of retrofitting or integrating new tools for sustainable inspection in existing lines. | Design of modular and retrofit-friendly systems for inspection. |

| Limited Expertise and Training | Operators might not have the skills needed to use AI-driven and automated inspection technology. | Expanding workforce training programs, as well as innovative user interfaces. |

| Material Compatibility Issues | Problems in detecting imperfections on recycled and eco-friendly inks because of different characteristics. | Advanced sensors and adaptable software algorithms designed for environmentally sustainable materials. |

| Fragmented Standards and Regulations | The diversity of sustainability requirements across different regions makes compliance more difficult. | The movement towards unified global standards and frameworks for sustainability certification. |

| Resistance to Change | Organizations are reluctant to embrace new workflows and technology to ensure sustainability. | Wider adoption of industry practices due to the digital transformation process and incentives for sustainability. |

Summary

Sustainability in printing inspection is an important step towards making greener practices for production in the packaging and printing industries. Through the adoption of intelligent, efficient waste reduction techniques and making an effort to improve energy efficiency, manufacturers can not only meet regulatory expectations but also enhance product quality, reduce costs and support global environmental goals.