How AI Defect Detection Reshapes Printing Inspection for Quality Assurance

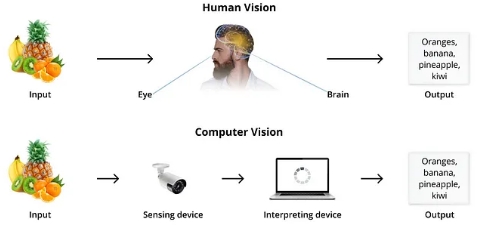

In the printing industry, where precision and consistency are essential, conventional methods of inspection often fail to provide 100% quality assurance. With increasing demands for speedy production and zero defect standards for packaging labels, security, and printing, AI defect detection has been recognized as a revolutionary technique in the field of printing inspection. Utilizing machine learning and computer vision technology, AI-powered printing inspection systems allow for the automatic defect detection in real-time of the smallest defects, and ensuring a superior quality control of prints.

Table of Contents

The Need for AI Defect Detection in Printing Inspection

Traditional methods for printing inspection, including manual inspections and traditional machine vision systems are increasingly not able to keep up with the speed of high-volume, high-speed printing. This increasing challenge has brought to light the necessity for AI deficiency detection, an integral part of modern quality control for printing.

Limitations of Traditional Inspection Approaches

Manual inspection is heavily dependent on the human eye and attention and both are susceptible to a lack of consistency and fatigue particularly under the stress of constant production. Traditional web inspection vision machine for printing quality rely on pre-defined criteria that don’t readily adjust to the natural changes in the design of prints, material, or environmental conditions. They often produce false positives, or fail to detect tiny flaws, leading to the waste of resources or undetected quality issues.

AI-powered Detect Defects

Artificial intelligence, especially deep learning, is an alternative that is transformative. Contrary to conventional methods, AI can be trained to detect acceptable print variations and differentiate it from imperfections. By exposing large amounts of printed prints, AI models learn what is considered a high-quality print, identifying even the most subtle flaws, such as streaks that are faint and minor misalignments or colors that are not in harmony. This ability significantly increases detection accuracy and minimizes false alarms.

How AI Defect Detection Works in Printing Inspection

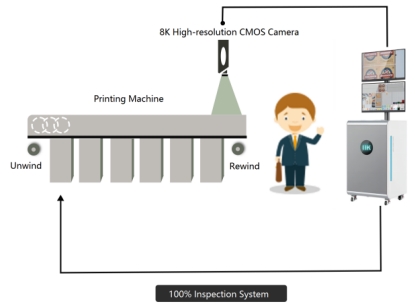

1. High-Resolution Image Acquisition

The process starts by capturing detailed, high-speed photographs of the printed items. Cameras, which are typically line-scan or area scan types, are strategically situated along the line of production to watch all of the printed material as it is moved. These high-resolution cameras work at high frame rates in order to keep pace with rapidly moving print webs, making sure that every defect is noticed. Lighting systems are created to give consistent light and minimize shadows or reflections that can obscure imperfections.

2. Preprocessing and Image Normalization

Before putting the photos into the AI model Preprocessing is required. This involves normalizing the images, by altering the contrast, brightness and alignment as well as other variations triggered by changes in conditions of lighting or the vibrations inside the machine. The process of preprocessing makes sure that the AI analyses images with the same parameters, which increases accuracy and reduces mistakes or false positives.

3. AI Model Inference Using Deep Learning

The core to the software is a deep learning model, typically known as a convolutional neural networks (CNN)–that examines frames frame by frame. The model was developed on a large number that include both defective and defect-free prints. In the course of training, it is able to distinguish between acceptable variations and real defects, for example:

- Color deviations

- Incorrect registration of print layers

- Smudges, streaks, and Blotches, smudges, and

- Incomplete characters or symbols

- Surface inconsistencies or substrate defects

Contrary to the traditional rule-based algorithm, AI models can adapt to the changing patterns of print and aren’t restricted to a fixed definition of flaws. They are able to detect irregularities in dynamic environments with high resiliency.

4. Real-Time Defect Detection and Classification

Once it is installed in the system, after deployment, the AI system analyzes images in real-time. If a defect is discovered it is classified according to its the severity and type. This information is immediately communicated to the operators via an interface for the user. In many instances the print inspection system is connected with the finishing or printing machine, allowing it to set alarms, reject prints that are defective or even stop the line to conduct further investigations.

5. Feedback Loop and Continuous Learning

AI system for detecting defects usually incorporate a feedback system. Operators can verify or alter the AI’s decision-making process and the results are utilized to further build and refine this AI model. This feedback loop guarantees an ongoing improvement of the system, allowing the system to be able to adapt to the new kinds of issues or changes in printing design over time.

6. Data Logging and Predictive Analytics

In addition to monitoring in real-time, AI systems log all inspection information, including images and timestamps, types of defects and locations. The historical data can be analysed to discover patterns, for example, frequent defects that occur at certain time, shifts or the machine’s settings. With this data, companies can take proactive actions to identify the root cause as they move away from reactive quality controls to proactive maintenance as well as process improvement.

Benefits of AI Defect Detection in Printing Inspection

1. 100% Inspection at High Speeds

AI-powered defect detection can provide 100% inspection at high speed making sure that each printed item can be analyzed automatically in real time, without slowing production. By utilizing advanced deep-learning and ultra-resolution image technology, the 100% printing inspection systems can detect the tiniest of defects, such as colors shifting, misalignments or missing components–at full line speed. This allows companies to maintain the same quality of printing, cut down on wasted paper, and spot issues immediately, which makes the ability to print at high speed and error-free an achievable reality in the current printing environment.

2. Enhanced Accuracy and Reliability

AI models, specifically those that employ deep learning excel in identifying a vast range of flaws with remarkable precision. From subtle color shifts, marks to more complex pattern inconsistencies and registration errors, AI can distinguish between acceptable variations and genuine imperfections. This decreases false positives and reduces the possibility of printing errors that go unnoticed, which ensures consistent high-quality prints.

3. Real-Time Inspection at High Speeds

In the fast-paced printing environment inspections are required without affecting the speed of production. AI systems run at high speed, analyzing every image in real-time. In conjunction with high-speed cameras and advanced computing technology, they will keep up with fast production lines and quickly detect and flag problems, without the need for bottlenecking.

4. Reduction in Waste and Rework

In the early stages of an operation, these AI-powered tools stop the continuance of faulty runs. This reduces not only the amount of waste, but also reduces time and energy involved in reprinting and repairing mistakes. In time, this can lead to an environmentally sustainable and cost-effective production process.

5. Adaptability to Design and Substrate Changes

In contrast to rule-based systems that need reconfiguration each time a print job AI models are extremely adaptable. AI models can be re-trained and fine-tuned quickly to work with various fonts, designs and substrates as well as finishes. This flexibility is particularly valuable in situations where short-run or custom-designed jobs are the norm.

6. Consistent Performance Without Fatigue

Human inspectors are susceptible to fatigue, particularly in long shifts or tasks that are repetitive. AI defect detection systems, however, ensure the same level of performance throughout the day regardless of the quantity or complexity of the job. This means that each print is scrutinized with the same degree of scrutiny, enhancing the overall quality of inspection.

7. Compliance and Customer Confidence

In highly regulated areas such as food packaging or pharmaceuticals the importance of a defect-free print is not only about aesthetics. It’s a legal obligation. AI guarantees that barcodes, labels, and warnings are clear and precise, thus which reduces the possibility of recalls or legal sanctions. Brand owners benefit from this because it increases trust and strengthens a reputation for high-quality.

Applications of AI Defect Detection in the Printing Industry

- Packaging Printing

In packaging, especially for food, pharmaceuticals, and consumer goods–AI systems detect defects such as blurred text, incorrect colors, missing print, and barcode errors. With the strict guidelines for compliance and branding, AI ensures that every package is legible and intact during production at high speed.

- Label Printing

AI-based inspection plays an essential part in label printing, in which precise logos, text along with serial numbers, are vital. The systems can verify aspects like precision of the placement, font integrity and micro-defects that could be overlooked through traditional inspection techniques or by human reviewers.

- Security and Currency Printing

In applications that require security, such as passports, banknotes, as well as certificates, an AI-powered inspections can detect fake attempts, microprinting error or even inconsistent ink. Through training AI models on authentic patterns, any deviation will be flagged automatically for further investigation.

- Commercial and Digital Printing

For flyers, brochures, as well as business document, AI software ensures layout uniformity, alignment accuracy, and correct color calibration. This is particularly important in short-run or customized digital print jobs where imperfections could differ from one item to the next.

- Industrial Inkjet and Wide-Format Printing

AI systems keep track of large surfaces, including wide-format industrial inkjet printing that is used for textiles, signage, and interior decor. They can detect dropouts, banding and nozzle issues, and guarantee uniform output across a variety of sizes of media and substrates.

Challenges and Future Solutions in AI Defect Detection for Printing Inspection

| Challenge | Description | Future Solution |

| Limited Training Data for Rare Defects | Certain defects are not frequent It is therefore difficult to collect enough data to build AI models efficiently. | Make use of artificial data generation as well as data enhancement methods, including the use of AI to simulate rare defect to increase training data sets. |

| High Initial Setup and Integration Costs | The implementation of AI inspection systems requires investments in the hardware, software and training. This can be a challenge for certain companies. | Create modular and adaptable AI solutions that are able to integrate with existing equipment in order to simplify and reduce initial costs. |

| Difficulty Detecting Subtle or New Defects | AI models can be unable to spot subtle flaws or flaws that haven’t been seen before. | Use the latest adaptive, continuous-learning systems and are constantly updating models in real-time in response to feedback from the operator and changes in defects. |

| False Positives Leading to Unnecessary Alerts | Extremely sensitive AI systems can detect acceptable deviations as problems that can cause inefficiencies and fatigue. | Enhance the precision of models by using improved training data, AI-human hybrid validation workflows and fine-tuning thresholds for detection. |

| Variability in Printing Materials and Conditions | The differences in the substrate as well as inks and lighting conditions can cause confusion to AI models and decrease accuracy. | Use solid preprocessing techniques, normalization methods and multi-sensor fusion techniques to maintain inputs in different conditions. |

| Scalability Across Diverse Printing Lines | The process of customizing AI models for various print jobs and equipment is time-consuming and resource-intensive. | Create generalized AI frameworks that allow for simple retraining modules that allow the learned knowledge to quickly adapt to the latest printing situations. |

| Data Privacy and Security Concerns | The storage and processing of print data, particularly for proprietary or sensitive content, poses security concerns. | Utilize edge computing to ensure that data processing stays on-site and include encryption and data handling protocols that are secure. |

Final Thoughts

AI defect detection and is changing how the printing inspection process is ensuring high-quality. Through providing fast, precise and flexible inspection capabilities, AI assists printers to reduce the amount of waste they produce, increase customer satisfaction and remain at the top of their game in a competitive market. As models become more reliable and easier to integrate, AI printing inspection will become the norm across every print segment.