What are Common Challenges Faced in Web Tension Control and How to Solve Them

Web tension control is essential in many industries, including printing, packaging, paper manufacture, and textile production, where continuous materials (or webs) like paper, plastic films, and textiles are produced. Maintaining optimum web tension is critical for assuring the final product’s quality and the efficiency of the manufacturing process. However, web tension control presents a number of challenges that engineers and operators must overcome in order to achieve the best outcomes. In this article, we will explore the challenges faced in web tension control and the strategies to overcome them.

What are the Common Challenges Faced in Web Tension Control

1. Variability in Web Material Properties

Variations in web material qualities are frequently encountered by web tension controller. Changes in thickness, width, and stretchability are examples of these differences. When the material properties are not consistent, it can be challenging to maintain precise tension control. For example, a thicker section of the web may require different tension levels than a thinner section.

2. Dynamic Changes in Speed

Web speeds in various manufacturing processes can fluctuate dynamically. Web tension can be affected by sudden accelerations or decelerations. Without the capacity to modify the tension management system as needed, the web can become slack or overly taut, resulting in web breaks or poor quality.

3. Web Wrinkling and Folding

Web tension control systems must prevent wrinkling or folding of the web, which can harm the material and disturb the manufacturing process. Web wrinkles can arise as a result of faulty roller alignment, insufficient web spreading, or excessive strain.

4. Slippage and Snagging

The slippage between the web and the rollers can lead to inconsistent tension control. In contrast, web snagging or jamming can halt production and damage the web material.

5. Environmental Factors

Temperature and humidity, for example, can have an impact on web tension control. Changes in these conditions may cause the web material to expand or contract, affecting its tension.

6. Complex Web Paths

In some processes, web materials follow intricate paths with multiple rollers and turns. Managing tension in such complex web paths can be challenging, as it requires precise coordination.

What are Key Strategies to Overcome the Challenges Faced in Web Tension Control

Variability in Web Material Properties

Web Inspection: Inspect the web material on a regular basis for fluctuations in thickness, width, or stretchability. Use web inspection vision system to identify and classify variances.

Tension Compensation: Use tension zones or dancer rollers that can respond to material changes. Adjust the tension control parameters for different web areas.

Dynamic Changes in Speed

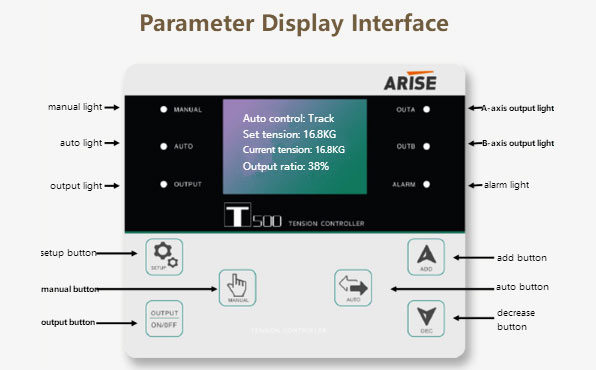

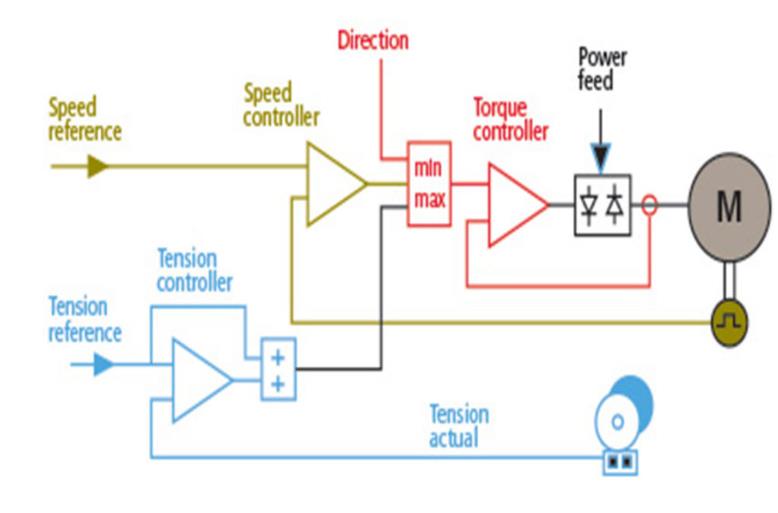

Closed-Loop Control: Invest in closed-loop tension control systems that can react to changes in web speed in real time. Sensors in these systems detect fluctuations and adjust tension accordingly.

Web Wrinkling and Folding

Proper Roller Alignment: To avoid wrinkles, make sure the rollers are exactly positioned and parallel to the web path. To keep alignment, use roller guides or edge sensors.

Web Spreading: Use web spreading devices or air bars to keep the web flat and wrinkle-free. These devices aid in the uniform distribution of strain over the span of the web.

Advanced Control Algorithms: Utilize tension control systems with advanced control algorithms capable of detecting wrinkles and correcting them as they occur.

Slippage and Snagging

Surface Properties: Select rollers with appropriate surface properties, such as coatings or grips, to minimize slippage. For preventing snags, ensure that rollers and guides are clean and well-maintained.

Environmental Factors

Controlled Environment: Maintain a controlled environment in the manufacturing area by managing temperature and humidity. Monitor environmental conditions with sensors and alter tension control systems accordingly.

Complex Web Paths

Accurate Alignment: Pay special attention to roller alignment in complex web paths. Utilize tension zones at key points to manage tension more effectively.

Customized Tension Zones: Design tension zones that suit the specific requirements of the complex web path. Tension control systems should be adaptable and configurable for the unique needs of your process.

Additional Best Practices

Regular Maintenance: Implement a routine maintenance schedule to verify that all tension control components, including as rollers, sensors, and tension control systems, are in good working order.

Operator Training: Provide sufficient training to operators and technicians so that they grasp the fundamentals of web tension control and how to successfully respond to difficulties.

Data Analysis: Utilize data logging and analysis tools to track tension fluctuations and detect patterns or trends. This can help in identifying the root causes of tension issues.

Continuous Improvement: Encourage a culture of continuous improvement by seeking feedback from operators and engineers to refine tension control processes and systems.

Conclusion

Many industries rely on continuous web materials, hence web tension control is crucial. Addressing the issues of maintaining exact web tension is critical for product quality, process efficiency, and downtime reduction. Manufacturers may efficiently negotiate the web of tension control difficulties and obtain optimal outcomes in their production processes by deploying modern tension controller, applying strict quality control procedures, and having a strong understanding of the dynamics of web materials.