6 Key Advantages of Implementing Web Guiding Systems in the Packaging Industry

Maintaining precision control over the web material during production processes is crucial in the packaging industry to ensure high-quality output. Many packaging industries are turning to web guiding systems to reach this degree of precision and efficiency. These innovative technologies automate web material control and guiding, resulting in faster production times, less waste, and higher overall product quality. In this article, we will look at the 6 key advantages of implementing web guiding systems in the packaging industry, as well as how they are modernizing the manufacturing process.

Enhanced Material Control and Accuracy by Implementing Web Guiding Systems

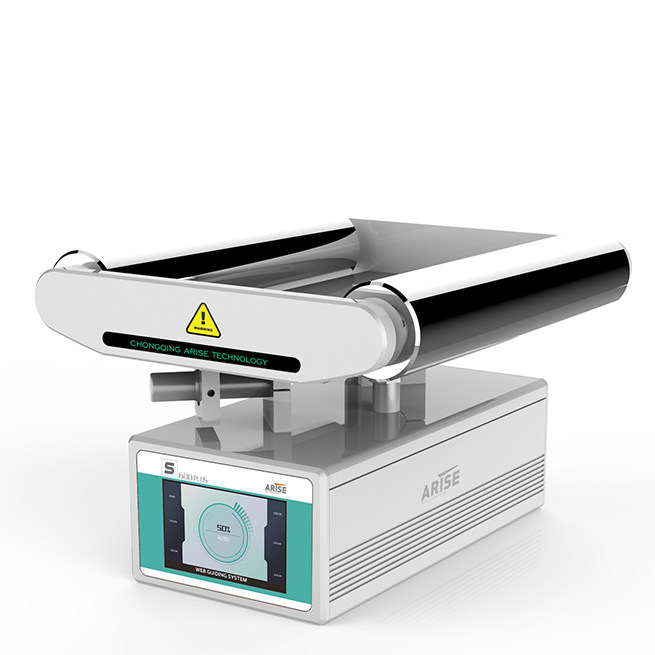

Web guiding systems provide unrivaled control and accuracy when dealing with various forms of web materials. These systems use sensors, cameras, and actuators to detect and fix misalignments, wrinkles, or irregularities in the web material, assuring accurate positioning throughout the manufacturing process. This level of control saves material waste, eliminates product faults, and improves overall packaging quality.

Increased Production Efficiency by Implementing Web Guiding Systems

By reducing manual intervention and human errors, web guiding systems improve manufacturing efficiency. These systems can automatically alter the alignment, tension, and speed of the web material, ensuring a continuous and smooth flow across the whole manufacturing line. Packaging firms may dramatically cut setup time, boost production speeds, and achieve greater throughput rates by eliminating the need for human adjustments.

Waste Reduction and Cost Savings by Implementing Web Guiding Systems

Web edge guide systems help to reduce waste and save money by reducing material waste and rework. These technologies prevent misalignment-related errors, such as slanted labels or uneven folds, by precisely guiding the web material. This defect reduction results in fewer rejected products and less material waste, ultimately saving packaging firms important resources. Furthermore, the precise control given by web guiding systems decreases the requirement for superfluous setup material and the possibility of manufacturing line stoppages, both of which cut costs.

Improved Product Quality and Customer Satisfaction by Implementing Web Guiding Systems

One of the most significant benefits of implementing web guide control system is the improvement in product quality, leading to increased customer satisfaction. By maintaining accurate web material positioning and tension, these systems eliminate variations that may result in product defects or inconsistencies. Consistently high-quality packaging instills customer confidence and enhances brand reputation. Moreover, precise web material control enables packaging companies to incorporate complex features such as holographic labels or intricate designs, elevating the visual appeal and perceived value of the packaged products.

Operator Safety and Ease of Use by Implementing Web Guiding Systems

By decreasing the need for manual intervention in the manufacturing line, web guide systems prioritize operator safety. Operators are less exposed to potential hazards connected with manual changes, such as entanglement or injuries caused by moving parts, by automating the web material control process. Furthermore, the web alignment system includes user-friendly interface and straightforward controls, making them easily accessible and manageable for operators of varied skill levels. This ease of use fosters a safer and more efficient workplace.

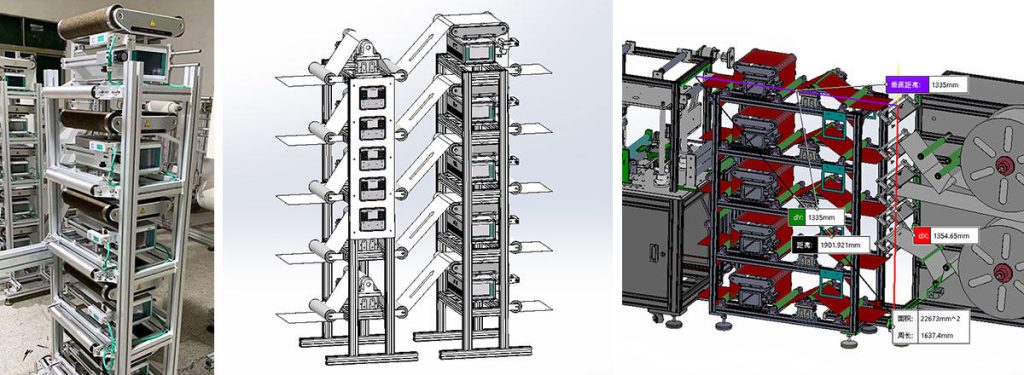

Adaptability and Versatility by Implementing Web Guiding Systems

In the packaging industry, implementing web guide systems provides customization and variety. These systems can be smoothly incorporated into a variety of packaging processes and can support a wide range of web materials, such as films, labels, and flexible packaging materials. The ability to handle different materials and adapt to diverse packaging requirements ensures that packaging companies can benefit from web guiding systems regardless of their specific needs, providing them with a competitive edge in the market.

Summary

The implementation of web guiding systems in the packaging industry provides numerous advantages. These solutions transform the packaging industry by ensuring precise and efficient operations while minimizing waste and increasing revenue. As the packaging industry evolves, web guiding control system will become increasingly important in fulfilling the needs of a fast-paced market and offering superior quality packaging to clients. Packaging firms can unleash efficiency, precision, and customer happiness by embracing these innovative technologies, positioning themselves as industry leaders in the dynamic world of packaging.