What Factors Affect the Accuracy of Web Guiding Systems?

When people discuss the accuracy of web guiding systems, they often quote a single number, such as “±0.1 mm.” In the real world, accuracy is not defined by any single component or parameter. It is defined by the way the whole system behaves in the real world.

When a web guiding system is not behaving as expected, the problem is often not “the guide is not accurate enough.” It is something in the process that determines how accurately the system can respond.

The following are the main factors that actually affect the accuracy of the web guiding systems.

Table of Contents

Sensor Type and Detection Quality

Accuracy begins with what the system can “see”. If it can’t see the web edge or reference point well, no controller or actuator can make up for it.

Materials can behave in very different ways when detected by a sensor. Transparency, reflection, low contrast, and irregularities can all impact detection quality. Even a high-quality sensor may not work well if the detection quality is poor because of dust, vibration, or inconsistent light.

In reality, several accuracy problems are incorrectly attributed to the guiding system when, in fact, they are sensor-related. Selecting the right sensor technology and applying it correctly can sometimes improve accuracy more than upgrading the entire system.

Mechanics and Actuator Performance

The mechanical design of the guiding system determines the boundaries of accuracy. A flexible frame, bearing play, or loose mounting causes mechanical errors that the controller cannot compensate for. This is particularly evident at high speeds or for broad webs. A stiff frame, robust mounting, and low deflection are essential.

Actuators are responsible for converting the detection into motion, and their resolution and speed are important. A high resolution is of little use if the actuator has a low response speed. Fast actuators with poor control can result in overshooting and oscillations. Servo-driven actuators are always preferred in demanding applications as they provide a good balance of speed, motion smoothness, and accuracy, whereas mechanical or pneumatic actuators usually struggle at high speeds.

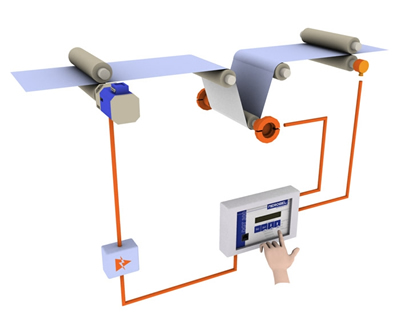

Control Tuning and System Behavior

The controller combines sensor information with actuator movement. It’s not just about getting to the desired position; it’s about staying there. The problem with some controls is that, unless specifically set, they can cause the machine to oscillate, correct too slowly, or constantly tweak back and forth without ever really settling. The default settings on most machines aren’t necessarily optimized. The tuning of the controls to suit line speed, material, and actuator characteristics is critical to establishing stable guiding accuracy.

Web Tension and Line Conditions

Even the best guiding system can be undermined by unstable tension. Uneven tension causes the web to stretch or shift unpredictably, which is especially problematic for thin or elastic materials. High-speed lines magnify these effects, making corrections less effective. Stable tension across the web width and along the production path is a prerequisite for reliable guiding.

In evaluating the line conditions for accuracy, the major factors to consider are:

- Web tension: If the tension is too low or inconsistent, the correction will be less efficient.

- Line speed: Increasing the line speed will increase the inertia of the material.

- Acceleration changes: If the line speed is constantly changing, the ability of the system to react quickly is compromised.

The tension should be kept consistent, and the speeds should be kept steady to ensure the system reacts as expected in real-world conditions.

Installation and Environmental Issues

The location and manner in which the system is installed directly affect accuracy. Small web spans, misaligned rollers, or large distances between sensor and actuator locations decrease correction efficiency. A properly designed web path enables smooth web motion, which can increase accuracy without modifying the hardware.

Environmental conditions, such as temperature, vibration, dust, and air flow, may contribute to accuracy degradation over time. Temperature expansion may alter sensor locations, while vibration can introduce noise. Dust and airborne particles can decrease sensor reliability.

Accuracy in a web guiding system is achieved when the entire system is considered. For example, the sensors must be able to detect well, the frame must be rigid, the actuators must be responsive, and the controller must be adjusted to the line and the material. Web tension, installation, and even the environment can also be contributing factors. Concentrating on one area is not likely to result in accurate outcomes.

At Arise, our web guiding systems are designed to take into account all these factors. With our accurate sensors, robust mechanics, and servo-driven actuators, our systems can keep your webs aligned and minimize waste.

Read more at Arise Web Guiding Systems.