How Web Guide Controllers Enable Customization in Evolving Packaging Trends?

In the packaging production line, small batch production, more SKUs, mixed materials, and stricter tolerances have gradually become the norm. From a marketing perspective, customization sounds great, but on the production floor, it brings considerable challenges.

And when it comes to coping with this transformation, one of the tools that we tend to overlook is the web guide controller.

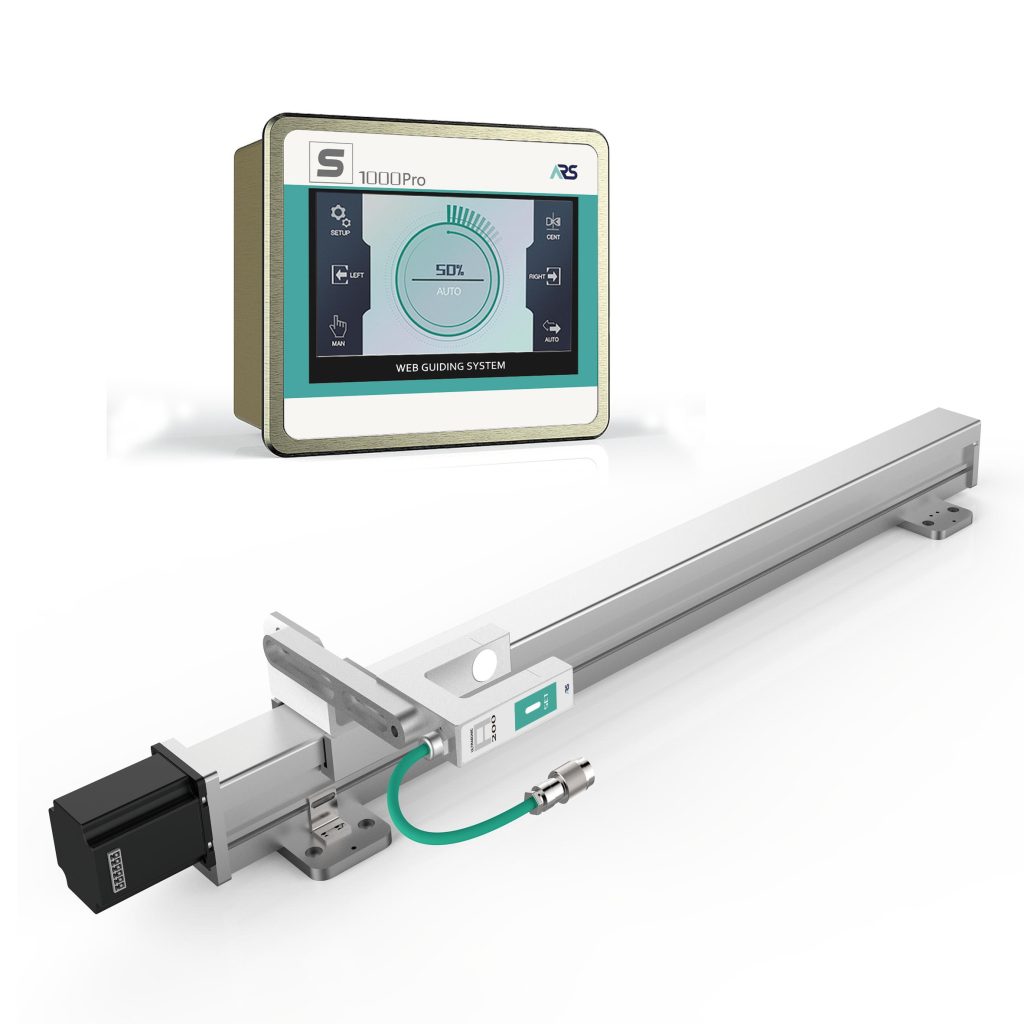

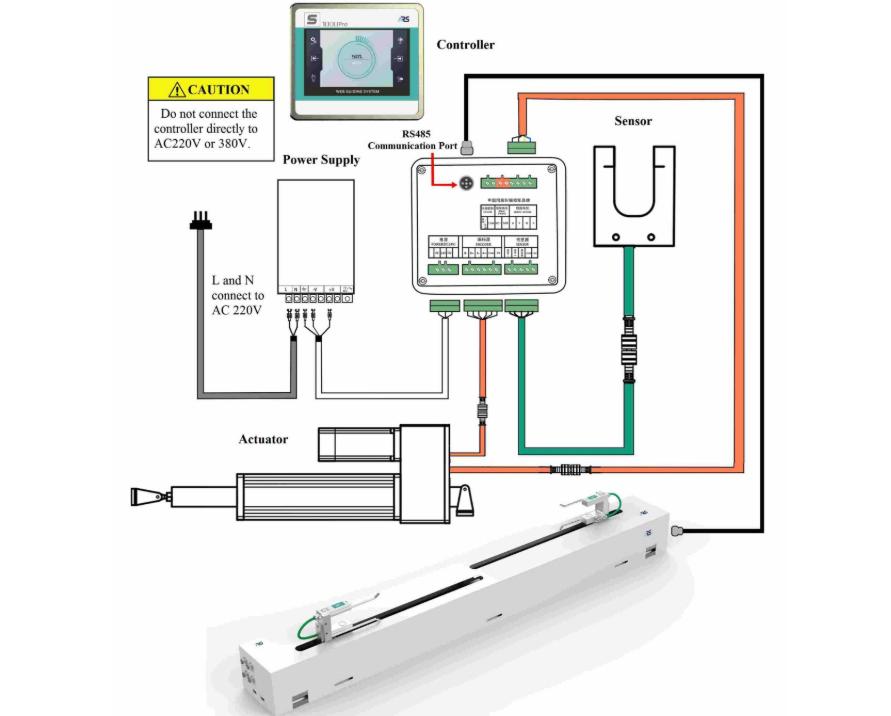

A web guide controller is an essential element of a web guide system employed in an industrial setup. Its role is to maintain the alignment of the continuous materials, which are actually referred to as webs. In this regard, it takes appropriate inputs from several sensors that monitor the appropriate position of the web in relation to a specifically designated point. Consequently, it adjusts the rollers or guides appropriately through an actuator, almost on an instantaneous basis, thus keeping the material appropriately centered in all operations involving printing, coating, laminating, and slitting.

This article will answer a simple question for you: How does the web guide controller achieve modernized customized packaging without reducing efficiency or increasing waste?

Custom Packaging Reqd for Higher Alignment Accuracy

Customized also likely translates into more variation: varied roll sizes, varied substrates, varied graphics, and sometimes varied line speeds, even on a single machine. The challenge is that generally, most packaging operations are still based on continuous web handling. Thus, if alignment is off, immediate symptoms appear as flawed labels, flawed lamination, flawed sealing, and flawed die-cuts, among others.

A web guide controller maintains the material running in a certain position regardless of changes. Instead of the operators aligning the guides or stopping the running material, the web guide sends responses immediately. This explains how the manufacturer changes the customized processes without necessarily re-engineering the entire system.

In short, customization makes sensitivity more. Web guiding makes sensitivity less.

Faster Job Changeovers Without Mechanical Adjustments

One big bottleneck in customized packaging is changeover time. Mechanical adjustments work, but they’re slow and operator-dependent. Every manual adjustment adds variability, and variability is the enemy of repeatability.

Alignment can be electronically adjusted with a web guide controller. Operators can fine-tune guiding behaviour, instead of physically repositioning components, when switching from one packaging format to another. Downtime is lessened, and short production runs are economically feasible.

This difference is huge for converters handling several private-label brands or frequent updates in design. Less setup time means more productive hours, even while batch sizes are shrinking.

Handling of Mixed and New Packaging Materials

Customization is sometimes tied to newer materials. For example, recyclable films, thinner laminates, alternative papers, and specialty finishes are all being seen as the norm. They are not as predictable as traditional packaging films. They stretch differently, respond to tension changes, and sometimes have different edge damage limitations.

A well-designed web guide controller can mitigate these material characteristics to a certain extent. This is achieved by ensuring that the web is held at a constant alignment regardless of the varying tensions or speed. This is crucial for lamination, coating, and cutting operations, where any small error can cause the product to fail altogether.

This leads to a lower number of rejected rolls and an increase in customer confidence while presenting new material options to customers.

Supporting Variable Widths and Modular Line Design

A specific packaging line is no longer designed to accommodate just one particular width; machines may be called upon to operate across various web widths without significant modification. This places further emphasis on the guiding system.

Web guide controllers enable the manufacturer to run different-width webs on the same line and still maintain precise positioning. Instead of building a machine for a single “ideal” web width, the converter can design a modular system to fit customer demand.

Here’s a basic comparison of the effect of guiding on flexibility:

| Without Web Guide Controller | With Web Guide Controller |

| Manual centering for each width | Automatic alignment across widths |

| Longer setup time | Faster changeover |

| Higher scrap during startup | Stable tracking from start |

| Limited customization | Scalable packaging formats |

This kind of flexibility is a key enabler for customized packaging strategies.

Maintaining Print and Seal Quality in Short Runs

As is learnt from short run manufacturing, error cannot be averaged out. Misalignment is immediately noticeable, leading to wastages.

Web guide controllers ensure accuracy throughout the entire process. This is beneficial in keeping print registration, sealing, and die cuts razor-sharp, not only in terms of product quality but also brand image. In addition, it minimizes the need for trained labor, which becomes increasingly difficult to find.

Scaling Customization Without Sacrificing Speed

Many companies are concerned that using customization hampers production speed. The truth, however, is that often, it’s not customization but irregular tracking on the web that hinders speed. This is where a web guide controller can help, as its usage can improve feed rates since alignment does not need to be manually performed, but rather through an automated system.

Web guiding is no longer just an accessory-it’s essential for modern packaging. Small misalignments can result in defects, waste, and downtime. A rugged web guide controller keeps your material centered and your line stable.

All of our controllers are integrated into a complete web guide system and handle different widths and speeds, in different materials, reducing scrap and easing short-run production. Take the time to contact us today to see just how our web guide systems can optimize your line and support your customization needs.