How to Prevent Web Slippage in Tension Control Systems?

Web slippage is frequently the main reason for the lack of stability in roll-to-roll tension control systems, resulting in unstable tension, poor register accuracy, and high material waste. It usually happens when the web is unable to transfer the needed torque because of low or unstable tension. Just raising the tension is not a solution that works well. The publication discusses the primary factors of web slipping and the proper web tension control systems that will not let it occur under real operating conditions.

Table of Contents

What Is Web Slippage in Tension Control Systems?

In systems of tension control, web slippage occurs as the roller does not receive enough friction force to transmit the needed torque. This phenomenon

can happen even with medium tensions.

Here are the main reasons:

- Unstable web tension

At times, the average tension level is said to be okay; however, the web may slide momentarily due to short-term variations. The slippage is more frequent during acceleration, deceleration, or speed changes rather than at constant speed.

- Mistaken torque at unwind or rewind

When brake or drive torque is different from the roll diameter, the web may slip on the roll surface. This is particularly the case for open-loop systems where the torque is not adjusted automatically.

- Changing roll diameter

The web tension produced by the same torque is different for the case of roll diameter decrease (unwinding) or increase (rewinding). Without compensation, tension drops or spikes happen, which in turn increases the risk of slippage.

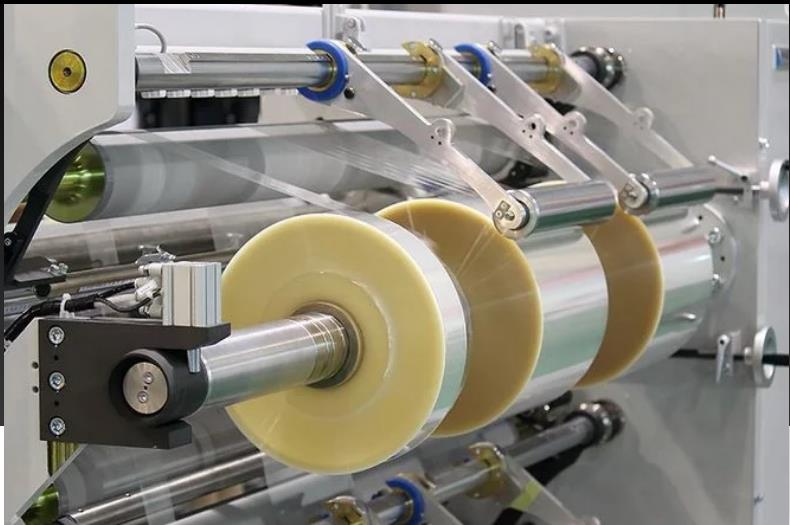

- Low-friction conditions

Smooth films, coated materials, dust, oil, and coating residues on rollers all contribute to the reduction of friction. Even if the tension settings are correct, slippage may still happen if the mechanical conditions are not ideal.

- Poor web path design

Insufficient wrap angle, misaligned rollers, or short web paths all result in a reduction of traction, which, in turn, makes the system more susceptible to disturbances.

The main point is that web slippage is generally a system-level issue rather than a single component failure.

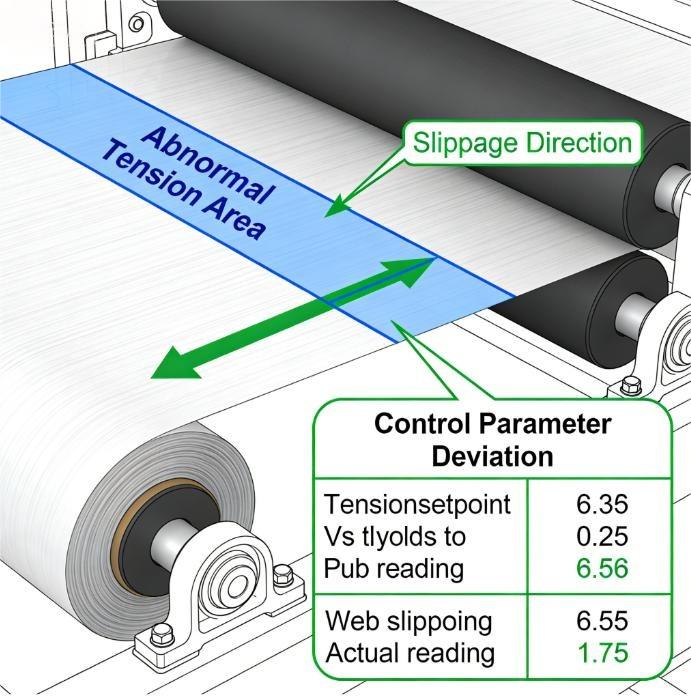

How Improper Tension Control Leads to Web Slippage

One of the main reasons for web slippage in roll-to-roll systems is improper web tension control. Proper control performance can, however, still create short-term tension loss that allows the web to. This is the case even when the average tension value seems to be right. These incidents usually happen during acceleration, deceleration, or disturbances in the process, thereby making it hard to notice them without adequate monitoring.

The following are the key tension control problems that can result in web slippage:

- First, there are the constraints imposed by open-loop tension control, where torque is merely estimated rather than being continuously adjusted according to actual tension feedback.

- Secondly, there is the slow controller response that leads to correction being delayed during speed or load changes.

- Next is the case of incorrect PID tuning, where tension oscillation occurs instead of stable control.

- Another cause is the lack of adequate compensation for roll diameter changes in unwinding and rewinding operations.

- Lastly, there is the issue of poor coordination between the various tension zones, which results in the formation of local low-tension areas within the web path.

When these problems arise, the only thing that higher tension does is to cover the problem, and at the same time, it introduces new risks like material stretching, deformation, or breaks in the web. To effectively prevent web slippage, the web tension control system must be a closed-loop one with fast response, stable feedback, and well-tuned control parameters that always maintain the desired tension level regardless of the operating conditions.

How to Prevent Web Slippage with Proper Web Tension Control Systems

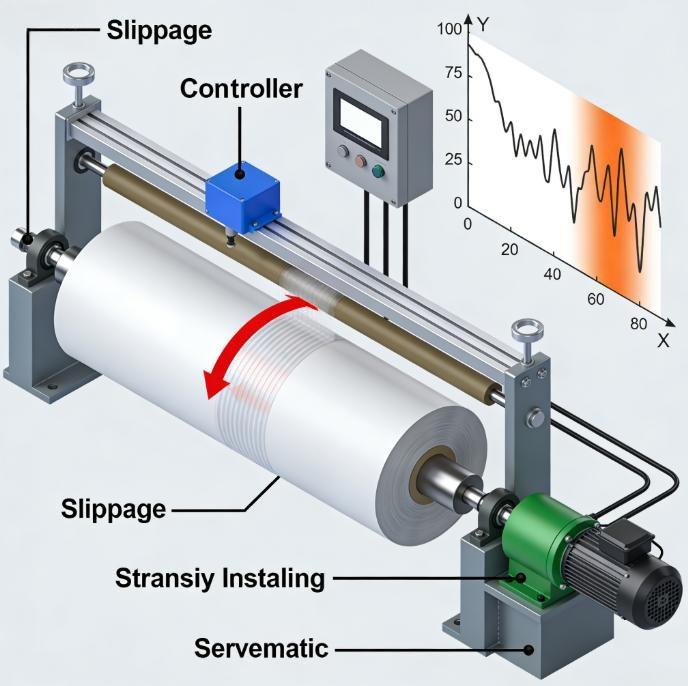

Web slip is prevented not only by increasing tension but by avoiding uncontrolled drops in tension. The most effective measure is to use a closed-loop web tension control system that measures web tension and constantly adjusts torque.

The main objective is that the system should seek the traction tension that is needed at all times. Slippage occurs immediately if tension falls below this threshold, briefly so during acceleration, deceleration, or splicing.

Second, the speed of control response is of utmost importance. Compared to the mechanical disturbance, the tension controller must have a faster reaction time. Late correction of torque at the brake or drive is one of the most common root causes of web slippage.

Third, the accuracy of roll diameter compensation is required. Wrong diameter tracking is the magic, which makes the torque mismatch, leading to this gradual or sudden loss of traction at the unwind or rewindides.

Thirdly, tension zones in multi-zone machines must be properly synchronized. Local tension drops between zones frequently cause slippage, even when the overall elevation of tension is apparently steady.

Web tension control systems that work efficiently should be very responsive, have good stability of minimum tension, and guaranteed torque matching, instead of emphasizing higher tension.

Why a High-Performance Web Tension Controller Reduces Web Slippage

The high-performance controller is responsible for ensuring that web slippage doesn’t actually occur, as it directly determines the speed and accuracy with which tension corrections are applied. The highest risk of slippage is during accelerating or decelerating or changes in roll diameter, while in actual production settings, slippage is much-rare event occurring.

As a manufacturer, we focus on key design elements that directly reduce web slippage:

- Fast control response to correct tension drops before slippage occurs

- More stable PID-tuned algorithms to avoid tension oscillations

- Accurate signal processing for reliable load cell and dancer feedback

- Compatibility with various types of drives and brakes, including servo motors and magnetic powder brakes

- Support for low-tension and high-speed applications, where the highest risk of slipping occurs.

In order to prevent web slippage, our web tension controllers serve as an active protection, thereby guaranteeing high system stability while faithfully following application-specific norming. They facilitate controlled, rather than strictly compensatory, processes in which greatly improved web stability, material quality, and, of course, production efficiency are assured.

Final

Web slip in tension control systems is, in fact, an indicator of inadequate balancing and response to the tension control. A correct diagnosis of the cause of the slip, followed by introducing a closed-loop web tension control system with instantaneous response and very accurate torque regulation, may result in constant and reliable web handling devoid of any slip.

To know more about the practicability of vital parameters in web tension control systems, web handling design, and tension controller selection, discuss the specifics of your application with us, or have a look at our other relevant technical materials: What Is Web Tension Controller?