Why Print Inspection Systems Are Critical for Brand Consistency

The enhancement of brand image is not merely a marketing issue. In the printing industry, it is also a crucial aspect of the production process.

For many brands, especially in the fields of packaging, labels and commercial printing, printed materials are often the only physical objects that customers can come into contact with. Color deviations, missing elements, inaccurate registration or variable data errors not only lead to waste but also reduce customer trust. Once trust is lost, it is very difficult to regain it.

That is why the printing inspection system has become a core component of brand protection.

This article will elaborate on the significance of the printing inspection system for brand consistency from the perspective of actual production environment.

Brand Consistency Is Enforced Through Quality Control in Printing

In real production situations, variation is inevitable. Press conditions drift, substrates vary, inks behave differently, and high-speed printing amplifies small errors. Over time, these factors create visible differences in output.

These variations often go unnoticed without automated print inspection, until the end of the production, when thousands of such inconsistent prints might already be present.

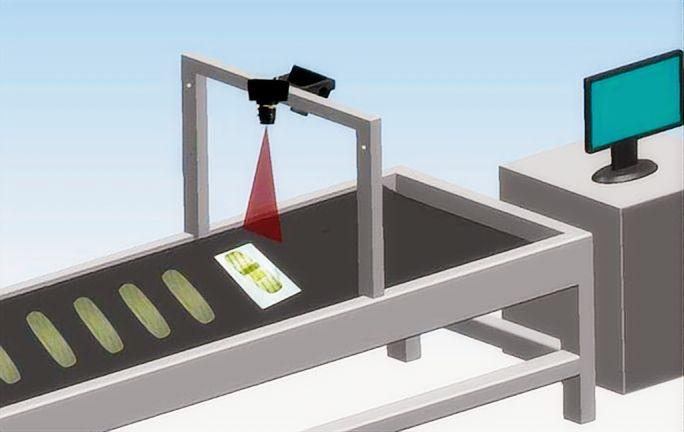

Print inspection systems continuously compare printed output against an approved reference. It means brand consistency is being directly enforced on the production line, not inferred from an occasional manual check.

Why Inconsistent Print Quality Damages Brand Trust

A single defect in printing is normally not a problem. However, the inconsistent quality of prints poses more harm.

Customers want the packaging to look the same each time they encounter the product. However, when the color of the packaging changes or the logo shifts slightly, the level of confidence plummets. In addition, in a regulated environment, inconsistency may call into question the level of compliance.

This is particularly true when applied in high-risk applications like:

- Pharmaceutical and medical packaging

- Food and Beverage Labels

- Consumer packaged goods

- Cosmetics and personal care products

In these markets, brand consistency is related to issues of safety, traceability, and authenticity. However, print quality inspection systems minimize this risk by ensuring that every printed unit has the same look and feel.

Manual Inspection Cannot Protect Brands at Production Speed

The current capacities of human inspection systems cannot match the printing capabilities that modern printing technologies achieve.

Operators must handle multiple printing process parameters because press speeds increase and print tasks become more difficult to execute. Operators face challenges that they must cope with during their work. Fatigue, distraction, and subjective judgment are unavoidable. Moreover, the output that operators actually verify constitutes only a small portion of the total production.

Print inspection systems do not show fatigue because they operate at maximum capacity to assess all produced materials without making any errors. The system executes its operational functions by assessing every produced item at maximum performance capacity. This process requires automatic inspection because brand consistency needs complete coverage and total accuracy, which manual inspection methods cannot deliver in large-scale operations.

Real-Time Detection Prevents Brand Damage Before Shipment

Most brand degradation does not occur when the problem is present. Most degradation occurs when the problem is absent from the product.

One of the big benefits of having a print inspection system is timing. The problem is recognized on the spot. There is no waiting until the end of the shift or the pallets are already wrapped. They are able to shut down earlier, fix the problem, and keep good and bad product separate.

Rather than reacting or correcting customer complaints or returns, manufacturers are in control upstream. This is the essence of correction and control, which is important for brand reputation.

Consistency Across Lines, Plants, and Suppliers

Brand owners seldom manufacture everything on a single press at a single location.

Multiple lines, multiple plants, and external suppliers make consistency harder to manage. Quality becomes subjective without objective inspection criteria, depending on local practices.

Print inspection systems provide a common reference. The same reference files, tolerances, and defect rules can be applied everywhere. This yields predictable output regardless of where production occurs, which is essential for brands operating at scale.

Brand Consistency Has Hidden Costs That Inspection Reduces

The cost of inconsistency is not limited to scrap and rework. Many of the most serious impacts appear later and are harder to quantify.

| Operational Costs | Brand-Level Costs |

| Scrap and waste | Customer complaints |

| Reprints | Loss of trust |

| Downtime | Retail rejection |

| Overtime | Reduced repeat orders |

Print inspection systems reduce both sides. While the operational savings are easy to measure, the long-term value lies in protecting brand credibility and customer confidence.

Print Inspection Is a Brand Protection Tool, Not Just Quality Control

Print inspection systems are often discussed as technical solutions. In reality, they are business tools.

They ensure that what a brand promises is what the customer receives, every time. They reduce uncertainty, prevent escalation, and support consistent brand presentation across markets and channels.

For companies that care about long-term brand value, relying on manual checks or end-of-line inspection is no longer enough. Brand consistency must be built into the production process itself.

That is exactly what print inspection systems are designed to do.