Key Sensor Technologies Used in Web Guiding Machines: Providing Real-time Feedback and Automated Adjustments in Web Handling

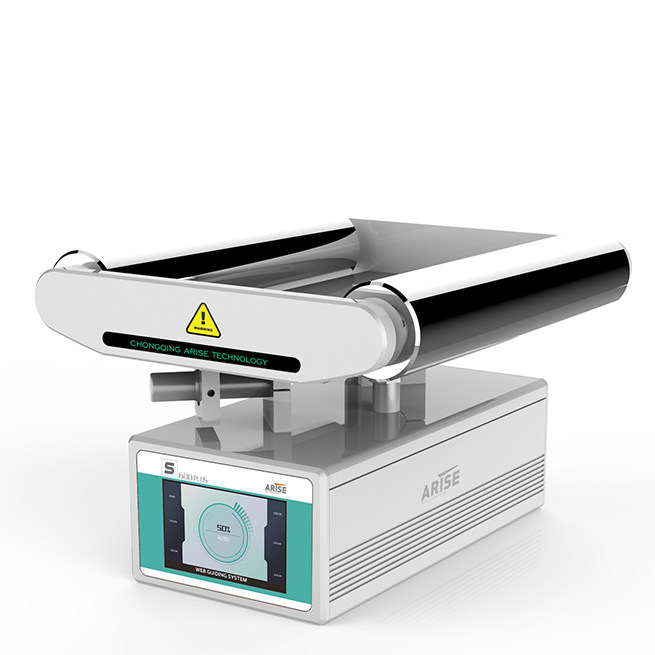

Web guiding system machines are essential in many industries where continuous web materials such as paper, film, textiles, or metal must be treated precisely. It is critical to provide exact web alignment and tension management in order to eliminate faults, reduce waste, and increase overall production efficiency. Sensor technologies embedded in modern web guiding machines have transformed the way web materials are handled, providing real-time feedback and automated Adjustments. In this article, we explore the key sensor technologies used in web guiding machines and their contributions to advancing precision and efficiency in web handling processes.

Line Edge Sensors Used in Web Guiding Machines

Working Principle of Line Edge Sensors

Line edge sensors operate by detecting changes in light, infrared, or sound patterns when the web material travels over the sensor’s field of view. Across the breadth of the web, the web edge sensor emits a beam of light, infrared radiation, or ultrasonic waves. When the web is appropriately aligned, the sensor receives a constant signal, indicating that the web is on its intended course.

The line edge sensor detects a shift in the signal pattern if the web deviates from its intended course. This causes the web guiding system to make precise adjustment to rectify the lateral position of the web, returning it to the centerline or desired alignment.

Types of Line Edge Sensors

Optical Line Edge Sensors

Light-emitting diodes (LEDs) are used in optical line edge sensors to emit a beam of light across the web width. The light pattern is detected by a receiver on the other side of the web. When the web is properly oriented, the receiver perceives a continuous light pattern. Changes in the position of the web produce changes in the received light pattern, allowing the sensor to calculate the lateral position of the web and offer input for directing corrections.

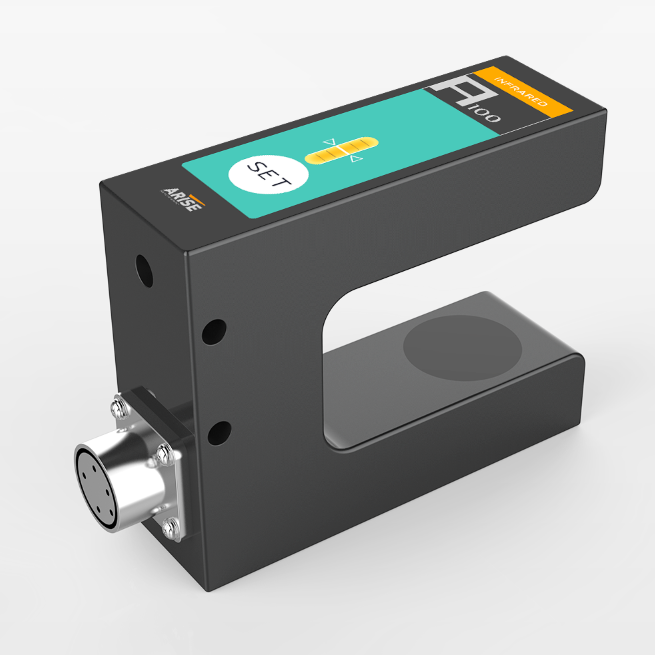

Infrared Line Edge Sensors

Infrared line edge sensors function similarly to optical sensors, but instead of visible light, they employ infrared radiation. Because they are less impacted by external illumination conditions, infrared sensors are especially effective in situations with low ambient light.

Ultrasonic Line Edge Sensors

Ultrasonic line edge sensors generate ultrasonic waves that bounce off the web before returning to the sensor. The sensor can estimate the distance and position of the web by measuring the time it takes for the waves to return. Ultrasonic sensors can guide materials with varied thicknesses and surface imperfections.

Capacitive Sensors Used in Web Guiding Machines

Capacitive sensors measure capacitance changes generated by web content passing close to the sensor. The capacitance changes as the dielectric constant of the material changes, allowing the sensor to detect the presence and position of the web. Capacitive sensors are especially effective for guiding non-conductive or low-conductive materials.

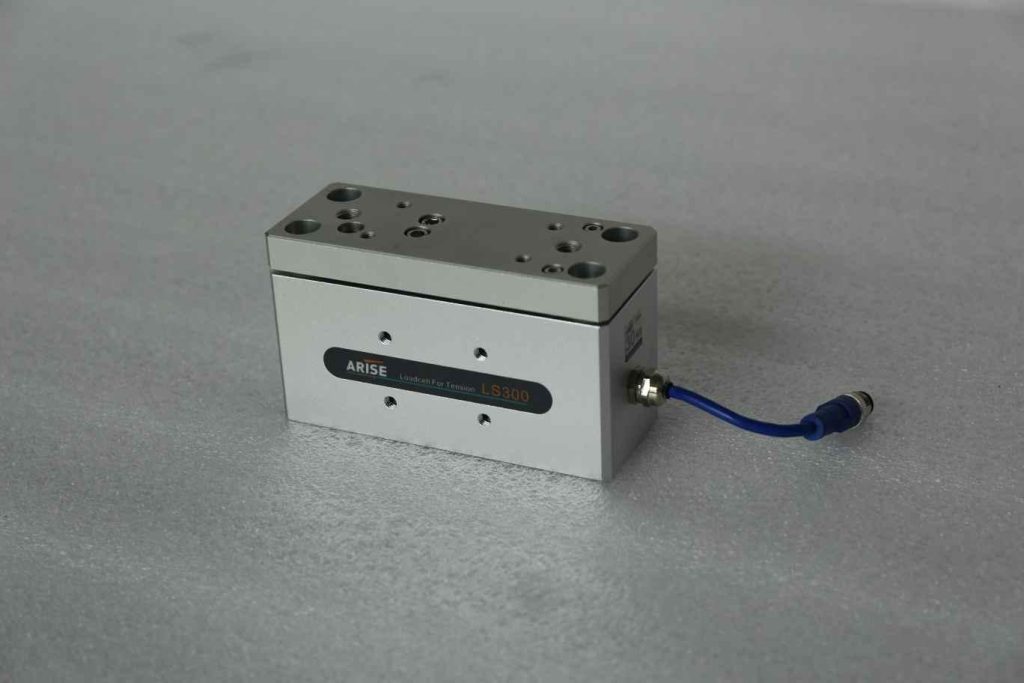

Tension Sensors Used in Web Guiding Machines

Tension sensors are critical components in web guide and tension control systems because they measure and monitor the tension forces imparted to a moving web material. These sensors are crucial in maintaining continuous and exact tension throughout the web handling process.

Types of tension sensors

Load Cells

Load cells are common tension sensors that work on the strain gauge principle. When tension is applied to the web, the load cell somewhat deforms. Strain gauges attached to the load cell detect this deformation, which is subsequently translated into an electrical output proportionate to the applied stress.

Dancer Roll Sensors

Dancer roll sensors are employed in applications that demand accurate tension management, such as in delicate or sensitive materials. The sensor detects the position or angle of a dancer roll, a free-moving roller that responds to variations in web tension. The dancer roll position gives feedback for tension adjustments.

Ultrasonic Tension Sensors

Ultrasonic tension sensors assess the distance between two places on the web using ultrasonic waves. These sensors give real-time tension feedback by continuously detecting the distance changes induced by tension fluctuations.

Magnetic Tension Sensors

Magnetic tension sensors detect changes in the strength of the magnetic field induced by web stress. They are often employed in applications that need non-contact sensing.

Laser Sensors Used in Web Guiding Machines

In web guiding applications, laser sensors provide excellent precision and accuracy. They detect the position of the web using laser beams and provide feedback for guiding adjustments. Laser sensors are suited for high-speed processing and precision-demanding applications.

Summary

Sensor technologies have transformed web guiding machines, providing real-time feedback and automated adjustments for perfect alignment and tension control of web materials. Industries may improve production efficiency, minimize waste, and reach higher levels of precision in web handling processes by employing these smart sensors.