The Critical Role of Web Guide Systems in Battery Manufacturing

The demand for high-performance batteries in electric vehicles, consumer electronics, and renewable energy storage drives the need for advanced manufacturing processes. Web guide systems play a crucial role in ensuring the quality and consistency of battery components. In this article, we’ll explore the critical role of web guide systems in battery manufacturing, their functionalities, and how they contribute to the production of reliable and high-performance batteries.

The Significance of Web Guide Systems in Battery Manufacturing

Battery manufacturing involves intricate processes where precise alignment and tension control are crucial for producing high-quality battery components. Any deviation in alignment or tension can lead to defects, reduced performance, and even safety hazards in the final product. Web guide systems address these challenges by providing precise control over the positioning, alignment, and tension of materials throughout the manufacturing process, ensuring uniformity and consistency.

Key Functions of Web Guide Systems in Battery Manufacturing

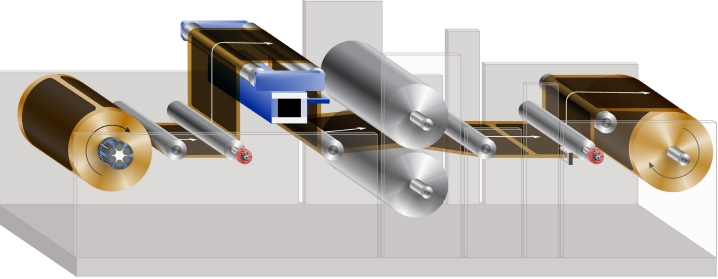

1. Alignment and Positioning

Web guide systems ensure the accurate alignment and positioning of battery materials, such as electrode foils, separators, and electrolytes, as they move through different manufacturing stages. Precise alignment is essential for maintaining uniformity and consistency in battery cell construction, minimizing defects, and optimizing battery performance.

2. Tension Control

Precise tension control is crucial for preventing wrinkles, creases, and tears in battery materials during processing. Web guide systems monitor and adjust tension levels to ensure smooth and stable material movement, resulting in high-quality battery components with optimal mechanical properties.

3. Edge and Center Guiding

Web guide systems can guide materials along their edges or centers, depending on the specific requirements of the manufacturing process. This flexibility allows for precise control over material alignment and tracking, minimizing waste and maximizing efficiency.

4. Slitting and Cutting

In addition to alignment and tension control, web guide systems can perform slitting and cutting operations to customize the widths and lengths of battery materials. This capability enables manufacturers to tailor battery components to meet specific design and performance criteria, enhancing product versatility and flexibility.

5. Material Handling and Tracking

Web guide systems facilitate the smooth and continuous movement of battery materials along the production line, ensuring efficient processing and minimizing downtime. These systems track the position and movement of materials, allowing for real-time adjustments and optimization of manufacturing parameters.

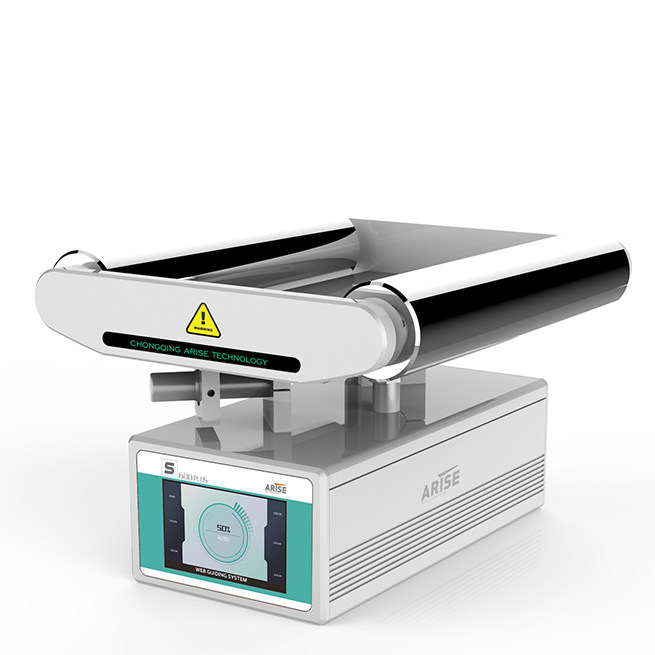

Advanced Features and Technologies in Web Guide Systems

Advanced features and technologies in web guide systems have revolutionized the way materials are handled and processed in various industries, including printing, packaging, and manufacturing. These innovations enhance accuracy, efficiency, and reliability, leading to improved product quality and increased productivity.

1. High-Resolution Sensors

Advanced sensors, such as ultrasonic sensors, line scan cameras, and laser sensors, provide precise measurement and detection of material position, alignment, and defects. High-resolution sensors enable accurate tracking and control of the web, even at high speeds and in challenging conditions.

2. Servo-Driven Actuators

Servo-driven actuators offer precise and responsive control over web guiding movements. These actuators use feedback mechanisms to adjust position, tension, and alignment in real-time, ensuring optimal performance and minimizing errors.

3. Closed-Loop Control Systems

Closed-loop control systems continuously monitor sensor feedback and make automatic adjustments to maintain desired web alignment and tension. These systems use feedback control algorithms to minimize deviations and optimize performance, resulting in consistent and reliable operation.

4. Integration with Automation Systems

Web guide systems can be seamlessly integrated with automation systems, such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems. Integration with automation systems enables centralized control, real-time monitoring, and data logging, improving efficiency and productivity.

5. Web Inspection and Defect Detection

Some advanced web guide systems incorporate web inspection and defect detection capabilities. Vision web inspection systems are used to detect the web for defects, such as wrinkles, tears, or misalignment. Automatic defect detection allows for immediate corrective action, reducing waste and improving product quality.

6. Remote Monitoring and Diagnostics

Web guide systems equipped with remote monitoring and diagnostics capabilities enable operators to monitor system performance and troubleshoot issues of the web guiding system from a remote location. Remote access to system data and diagnostics tools facilitates proactive maintenance and minimizes downtime.

7. Adaptive Control Algorithms

Adaptive control algorithms continuously adapt system parameters based on changing operating conditions, such as material properties, speed variations, or environmental factors. Adaptive control algorithms optimize performance and minimize errors, ensuring consistent operation under varying conditions.

8. Safety Features

Advanced web guide systems incorporate built-in safety features, such as overload protection, emergency stop mechanisms, and safety interlocks, to ensure safe operation and protect equipment and personnel from potential hazards.

9. Data Logging and Analytics

Web guide systems can collect and analyze data on material position, tension, and alignment over time. Data logging and analytics tools provide valuable insights into system performance, identify trends, and optimize operating parameters for improved efficiency and productivity.

Conclusion

By providing accurate alignment, tension control, and material handling capabilities, web guide systems contribute to the production of high-quality batteries with superior performance and safety characteristics. As the demand for advanced batteries continues to grow, the importance of web guide systems in battery manufacturing will only increase, driving further innovation and optimization in this essential industry.