Advancements in Web Guide System Technology

The advancement of web guide system technology has significantly improved the efficiency and precision of many industrial processes. Significant progress has been achieved in the development of web guide systems over the years, leading in increased automation, improved performance, and better flexibility.

Key Innovative Technologies in Web Guide Systems

1. Automation and Precision

a. Sensor Technologies

Advanced Sensors: Modern web guide systems use cutting-edge sensor technologies like ultrasonic sensors, infrared sensors, and line lasers. These sensors detect web edges in real time and with high precision, enabling accurate alignment.

Web Edge Detection: Sensors enable exact determination of the web’s position, allowing for automated modifications to maintain ideal alignment.

b. Closed-Loop Control

Automated Correction: The integration of closed-loop control systems ensures that web alignment is continuously monitored and automatically corrected. This reduces the need for manual intervention, lowering the likelihood of errors.

Real-Time Adjustments: Closed-loop systems enable real-time adjustments, contributing to seamless and efficient web handling during production.

2. Integration with Industry 4.0

a. IoT Connectivity

Internet of Things (IoT): Web guide systems are increasingly part of Industry 4.0 initiatives, offering connectivity through IoT. This allows for remote monitoring, data analytics, and predictive maintenance.

Data-Driven Insights: The integration of web guide systems into IoT networks provides valuable data-driven insights, facilitating informed decision-making and optimizing operational efficiency.

b. Data Exchange

MES Integration: Web guide systems seamlessly integrate with Manufacturing Execution Systems (MES), allowing for effective data sharing. This integration facilitates greater coordination across many parts of the production process.

Real-Time Reporting: MES integration enables real-time reporting, increasing visibility into production data and supporting proactive decision-making.

3. Advanced Control Algorithms

a. Adaptive Control

Dynamic Adjustments: Web guide systems now employ adaptive control algorithms that continuously optimize parameters based on real-time conditions. This adaptability ensures effective performance in diverse operating environments.

Self-Optimizing Systems: The adaptive nature of control algorithms enables web guide systems to self-optimize, adjusting to variations in materials and operating conditions.

b. Predictive Algorithms

Historical Data Analysis: Predictive algorithms analyze historical data to anticipate potential issues. This proactive approach allows the system to make adjustments before deviations impact alignment.

Preventive Maintenance: Predictive algorithms contribute to preventive maintenance strategies, reducing downtime and extending the lifespan of web guide systems.

4. Improved Material Handling

a. Variable Web Width Handling

Automated Adjustments: Advanced systems can handle variations in web width without manual adjustments. This automation supports seamless transitions between different products or specifications.

Flexibility: The ability to handle variable web widths enhances the flexibility of manufacturing processes, accommodating diverse production requirements.

b. Tension Control

Precision Tension Management: Web guide systems now have powerful tension control features. This guarantees that tension levels remain consistent throughout the production process, eliminating wrinkling and stretching.

Enhanced Product Quality: Precise tension control enhances product quality, especially in applications where material integrity is critical.

5. Enhanced User Interfaces

a. Touchscreen Controls

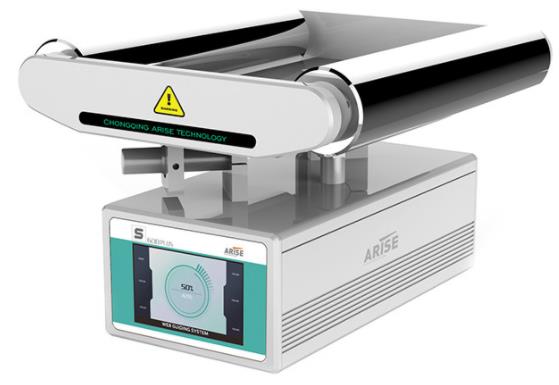

Intuitive Interfaces: User interfaces have evolved to feature intuitive touchscreen controls. This simplifies the setup process, making it easier for operators to configure and monitor the system.

Visual Representation: Touchscreen interfaces often provide visual representations of web alignment, aiding operators in assessing and adjusting the system in real-time.

b. Remote Accessibility

Centralized Monitoring: Many modern web guide systems offer remote accessibility. This allows operators to monitor and control the system from a centralized location, improving overall operational efficiency.

Remote Troubleshooting: Remote access enables faster troubleshooting for web guiding system and minimizes the need for on-site interventions, resulting in less downtime.

6. Applications Across Industries

| Industry/Application | Use Cases |

| 1.Printing and Converting | Ensures precise alignment in printing, minimizing misprints and improving print quality. Contributes to accurate cutting and finishing in converting processes, enhancing label and packaging quality. |

| 2. Packaging | Critical for packaging lines to ensure accurate alignment, leading to precise sealing, labeling, and forming of packages. |

| 3. Textiles | Contributes to accurate alignment of fabrics in textile manufacturing, preventing distortions and defects in final products. |

| 4. Paper and Pulp | Vital in the paper and pulp industry, guiding the continuous flow of paper through various production stages. |

| 5. Flexible Packaging | Ensures quality in the production of flexible packaging materials, including pouches and wrappers. |

| 6. Labeling | Plays a crucial role in labeling applications, contributing to accurate label placement and alignment. |

| 7.Pharmaceutical Packaging | Essential for ensuring accurate alignment in pharmaceutical packaging, including dosage information and barcodes. |

| 8. Continuous Printing | Facilitates continuous printing processes, ensuring precise alignment for consistent print quality. |

| 9. Textile Printing | Contributes to accurate alignment in textile printing, enhancing the quality of printed fabrics. |

Future Trends of Advanced Web Guide Systems

1. Integration with Artificial Intelligence (AI)

Predictive Analytics

AI Algorithms: Integration with AI algorithms will allow for predictive analytics to anticipate and prevent alignment concerns. This proactive strategy reduces downtime and maximizes performance.

Self-Optimizing Systems: AI-driven systems will become more self-optimizing, continuously learning from data to adapt and improve alignment precision based on historical and real-time information.

2. Evolution of Sensor Technologies

High-Precision Sensors

Nanotechnology Integration: Advancements in nanotechnology will lead to the development of high-precision sensors capable of even more accurate web edge detection, ensuring optimal alignment.

Multi-Sensor Fusion: Integration of multiple sensor types, including vision sensors and advanced optical sensors, will enable comprehensive data fusion for a more nuanced understanding of the web’s position.

3. Continued Sensor and Software Innovations

Innovations in Web Edge Detection

Edge Computing: Edge computing technologies will enable faster processing and decision-making at the sensor level, driving further advancements in web edge detection.

Advanced Software Solutions: Continued improvements in software solutions will be critical in improving the overall performance and capabilities of online guide systems.

Conclusion

Advancements in web guide system technology have had a substantial impact on production processes across multiple industries. The combination of automation, accuracy, and connectivity has enhanced production line efficiency while also contributing to higher product quality and waste reduction. The future of web guide systems offers a convergence of cutting-edge technologies, increasing intelligence, and a commitment to sustainability.