How to Install A Web Guide System : Best Practices for Installation and Calibration

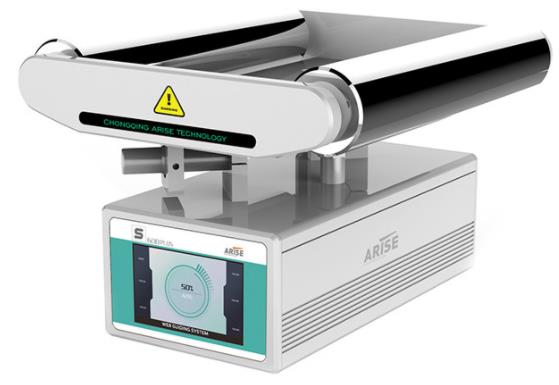

A web guide system is essential in industries where precision is critical, such as printing, packing, and paper manufacture. These methods ensure that the web content is accurately aligned and tracked throughout the production process. However, in order to attain peak performance, the web guide systems must be properly installed and calibrated. This article will explore the topic of how to install a web guide system, providing the best practices for installing web guide system, ensuring efficient operation and minimal downtime of the manufacturing machine.

Preparation Work for the Installation of Web Guide System

It is critical to conduct extensive preparation before beginning the installation process. This includes going over the system specifications, completing a site reconnaissance, and making sure that all relevant components and tools are on hand. Familiarize yourself with the manufacturer’s instructions and guidelines, as they contain important information relevant to the web guiding system being installed.

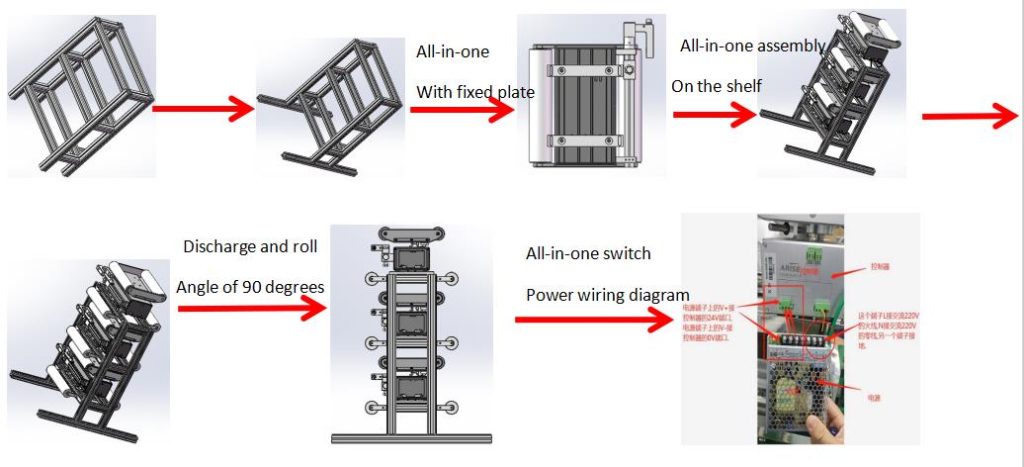

Proper Mounting and Alignment for the Installation of Web Guide System

The web guide system’s installation is vital to its functionality. Choose a place that allows for easy maintenance and adjustment. Make sure the mounting surface is strong enough to hold the weight of the system. Follow the manufacturer’s recommendations for mounting height, distance from adjacent equipment, and any other specifications.

Proper alignment is essential for accurate web tracking. Align the web guide system parallel to the web path, making sure it is perpendicular to the web material’s direction. To attain the appropriate alignment, use precise leveling tools. Any misalignment during installation can cause tracking problems and degrade system performance.

Web Path Preparation for the Installation of Web Guide System

It is critical to prepare the web path before installing the web guide system. Make sure the road is free of debris, obstacles, and other sources of vibration. A clear and unobstructed web path lessens the possibility of web material breakage and tracking errors.

Inspect the rollers, pulleys, and other web path components for evidence of wear or damage. Replace any worn-out parts to ensure smooth web movement. It is also beneficial to clean the web path thoroughly to remove dust, dirt, or residue that may hinder the system’s operation.

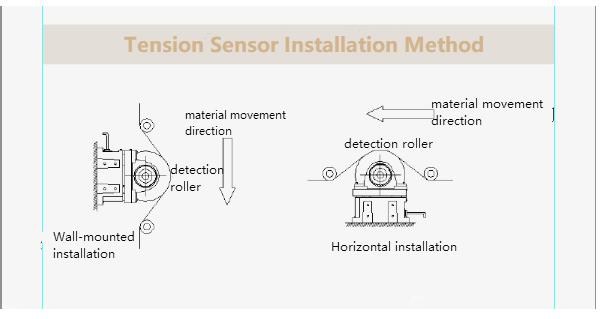

Sensor Placement During the Installation of Web Guide System

Sensor placement is critical in the installation and calibration of web guide control system. The sensors monitor the location and alignment of the web material, which allows the system to make the necessary modifications for accurate tracking. Here are some guidelines for sensor placement:

Proximity to the Web Material

Place the sensors as close to the web material as feasible while avoiding contact. This guarantees that the sensors can detect the location and alignment of the web precisely. If the sensors are too far apart, they may struggle to track the web effectively, resulting in tracking mistakes.

Parallel Alignment

Align the sensors such that they are parallel to the web path. This alignment enables the sensors to correctly track the movement of the web material. Misalignment might provide erroneous readings and have an impact on the system’s tracking performance. Use precision leveling tools to ensure that the sensors are correctly aligned.

Multiple Sensor Placement

Depending on the intricacy of the web path and the desired tracking precision, many sensors may be required. Placing sensors along the web path at crucial points provides a full view of the web’s position and alignment. As a result, the system can make more exact modifications, resulting in better tracking performance.

Sensor Stability

Make sure the sensors are properly fastened to avoid any movement or vibration during operation. Web guide sensors that are loose or unstable can result in erroneous readings and tracking problems. To ensure stability, use the manufacturer’s suggested mounting brackets or fixtures.

Lighting Conditions

Take into account the lighting conditions in the installation area. Excessive glare, shadows, or illumination fluctuations can all degrade sensor performance. Ensure that the sensors are not exposed to direct sunlight or strong light sources that may interfere with their ability to detect the web material accurately.

Calibration Process in the Installation of Web Guide System

The calibration process for web guide systems is adjusting the system’s parameters to match the online material and achieve accurate tracking. Calibration guarantees that the system can make accurate modifications to keep the alignment needed. The following are the steps in the calibrating process:

Gather Information

Gather necessary information about the web material and the specific requirements of your production process before beginning the calibration procedure. Details such as web width, desired alignment accuracy, and web speed are included. Specific rules and recommendations should be found in the manufacturer’s literature.

System Configuration

To configure the parameters, use the system’s control interface or software. Enter the required data, such as web width, speed, and desired alignment precision. The control interface may include options for adjusting sensor sensitivity, control response, or other parameters relevant to the system.

Test Run

To evaluate the system’s initial performance, do a test run with a sample web material. Examine how the system tracks the site content and whether it keeps the desired alignment. Pay close attention to any tracking mistakes or departures from the expected path during this test.

Adjustment Iterations

Adjust the system’s parameters based on the results of the initial test run to improve tracking accuracy. You may need to fine-tune factors such as sensor sensitivity, control reaction time, or filtering settings depending on the system. These modifications will differ depending on the system and its capabilities.

Repeat Test Runs

Repeat the test run with the sample web material after making any necessary edits. Examine the tracking performance of the system and compare it to the required alignment. If necessary, continue fine-tuning the parameters and repeating the test runs until the desired tracking accuracy is achieved.

Fine-tuning

Consider additional fine-tuning choices to optimize the system’s performance once it has accurately tracked the online material. This could include modifying tension control mechanisms, edge detection settings, stability controls, or other system-specific factors. If necessary, consult the manufacturer’s documentation or get expert guidance.

Regular Maintenance and Monitoring after the Installation of Web Guide System

Once the web guide system has been built and calibrated, frequent maintenance and monitoring are required to guarantee that it continues to work well. Implement a preventive maintenance routine that includes inspecting and cleaning the system’s sensors, rollers, and other components. Check for indicators of wear, misalignment, or other issues that may compromise the system’s performance on a regular basis.

During production runs, keep an eye on the system’s performance for any deviations or tracking problems. Analyze performance statistics and make appropriate adjustments using the system’s control interface or software. Address any issues that develop as soon as possible to reduce downtime and ensure consistent product quality.

Summary

Web guide system installation and calibration are crucial for attaining accurate web tracking and ensuring effective manufacturing operations. You may reduce tracking errors, downtime, and overall productivity by following the best practices mentioned in this article. Remember to follow the manufacturer’s instructions and seek expert advice if needed. With a properly fitted and calibrated web guide system, you can optimize your processes and reliably provide high-quality products.