How to Mitigate Vibration in Web Guide Systems to Achieve High-accuracy Results

Accurate web guiding is critical in various industrial processes involving materials like paper, film, textiles, and metals. Vibrations can severely impact web guide systems, causing misalignment, quality defects and increased material waste.

Understanding the Impact of Vibration on Web Guiding

Web guiding systems ensure that a moving web follows a precise path through processing machinery. Vibrations whether from machinery, environmental factors, or the web material itself, can disrupt this precision, leading to costly errors and inefficiencies.

Sources of Vibration in Web Guide Systems

- Mechanical Imbalances: Unbalanced rollers or rotating components introduce vibrations.

- Environmental Factors: Vibrations from adjacent machinery or structural vibrations affect the web guiding system.

- Operational Speed: High-speed operations can exacerbate even minor vibrations.

- Material Properties: Variations in tension and stiffness within the web material can lead to vibrational problems.

Strategies to Mitigate Vibration in Web Guide Systems

Implementing effective strategies to mitigate these vibrations is crucial for maintaining the accuracy and efficiency of web guide systems.

1. Mechanical Solutions

Precision Engineering:

- Balanced Components: Ensure all rotating parts, such as rollers and shafts, are balanced and aligned. This reduces the primary sources of vibration.

- High-Quality Bearings: Use high-precision bearings that reduce friction and wear, thereby minimizing vibration.

- Proper Lubrication: Regular maintenance and lubrication of moving parts to reduce wear and vibration.

Damping Mechanisms:

- Vibration Isolators: Install isolators between the machinery and its mounting base to absorb and dampen vibrations.

- Shock Absorbers: Use shock absorbers on components that experience sudden movements or impacts.

Structural Reinforcement:

- Stiffening Frameworks: Strengthen the machine’s frame and supports to prevent vibration transmission.

- Foundation Modifications: Ensure the machinery is mounted on a solid foundation to reduce external vibrations.

2. Operational Adjustments

Speed Regulation:

- Optimal Speed Settings: Operate the machinery at speeds that avoid resonant frequencies, reducing the amplification of vibrations.

- Gradual Acceleration and Deceleration: Implement controls for smooth changes in speed to minimize sudden vibrational shocks.

Tension Control:

- Consistent Web Tension: Maintain uniform tension across the web to prevent fluctuations that can cause vibrations.

- Automated Tension Adjusters: Use automated tension controllers to continuously monitor and adjust web tension in real-time.

3. Advanced Control Systems

Feedback Loops:

- Real-Time Monitoring: Implement sensors to continuously monitor the web’s position and adjust the guiding system dynamically.

- Closed-Loop Control: Utilize closed-loop control systems to make precise adjustments based on real-time data.

Active Vibration Control:

- Dynamic Countermeasures: Use sensors and actuators to detect and counteract vibrations actively.

- Smart Actuators: Employ actuators that can adjust positioning and damping in real-time to mitigate vibrations.

4. Technological Innovations

Machine Learning and AI

- Predictive Maintenance: Use AI algorithms to predict when parts will fail or need maintenance, reducing unexpected vibration sources.

- Adaptive Control Systems: Implement machine learning models that adapt the web guiding system’s responses based on historical data and real-time inputs.

High-Precision Sensors

- Enhanced Detection: Use high-precision web guide sensors to detect even minor deviations in web position and correct them promptly.

- Integrated Sensor Networks: Create a network of sensors that provide comprehensive data for better control and adjustments.

Digital Twin Technology

- Simulation and Optimization: Create a digital twin of the web guiding system to simulate different operating conditions and optimize performance.

- Predictive Analysis: Use the digital twin to predict the impact of changes and make informed adjustments to the physical system.

5. Implementation Plan

- Assessment: Begin with a comprehensive analysis of the existing system to identify vibration sources.

- Design Optimization: Redesign components and structures, incorporating precision engineering and damping mechanisms.

- Control System Integration: Implement advanced control systems that provide real-time feedback and active vibration control.

- Testing and Calibration: Conduct extensive testing to ensure effectiveness under various conditions, followed by fine-tuning.

- Continuous Monitoring: Establish ongoing monitoring to track performance and make necessary adjustments.

Why Choose High-accuracy Arise Web Guide System

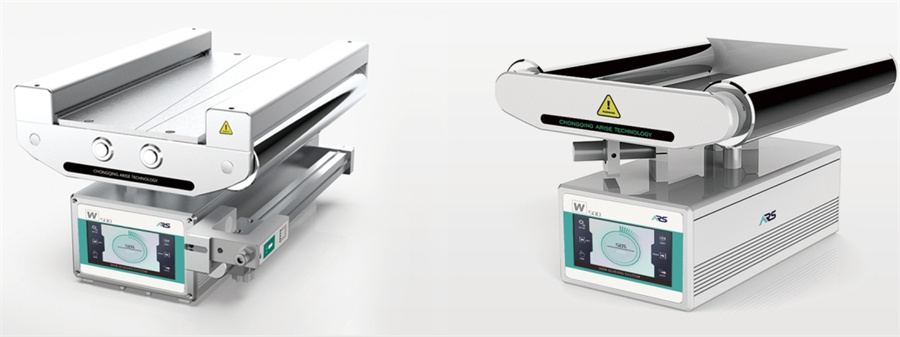

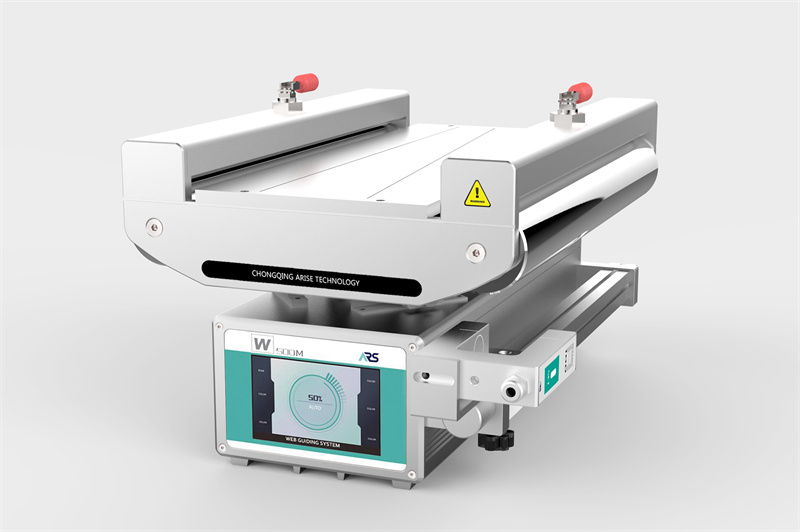

Introduction of Arise Web Guide System

The Arise all-in-one web guide systems provide a high-performance solution featuring full touch screen operation. Specifically designed for tracking material edges, lines, and contrast, it excels in automatic web guiding during material movement, adopting ultrasonic, infrared, or CCD sensors for signal detection. It ensures accurate and efficient web guiding processes.

The web guide system with a splice table features a manual automatic paper pressing platform to simplify material replacement, widely used in the label, flexo printing, and paper bag industries.

Outstanding Features of Arise Web Guide System

The Arise web guiding control system equipment stands out for its unparalleled precision and reliability, making it the optimal choice for industries that require meticulous web alignment.

- Superior Accuracy: Utilizing advanced sensors and real-time feedback loops, the Arise system ensures precise web positioning, minimizing misalignment and product defects.

- Robust Vibration Mitigation: Engineered with state-of-the-art damping mechanisms and active vibration control, the system effectively reduces vibrations, ensuring consistent performance even in high-speed operations.

- Advanced Technology Integration: Incorporates machine learning and AI for predictive maintenance and adaptive control, optimizing system performance and reducing downtime.

- Durability and Reliability: Built with high-quality materials and components, the Arise Web Guide System offers long-lasting durability and minimal maintenance requirements.

- User-Friendly Interface: Web guiding equipment features an intuitive interface for easy operation and quick adjustments, enhancing productivity and reducing training time.

Choosing the Arise web guide system means investing in precision, efficiency, and advanced technology to achieve superior web guiding performance.