Web Guiding System

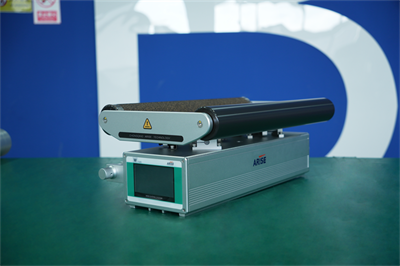

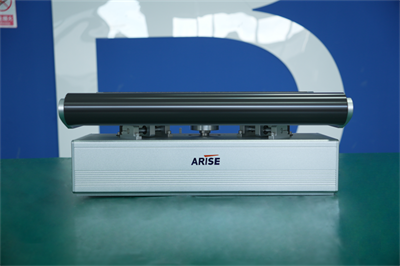

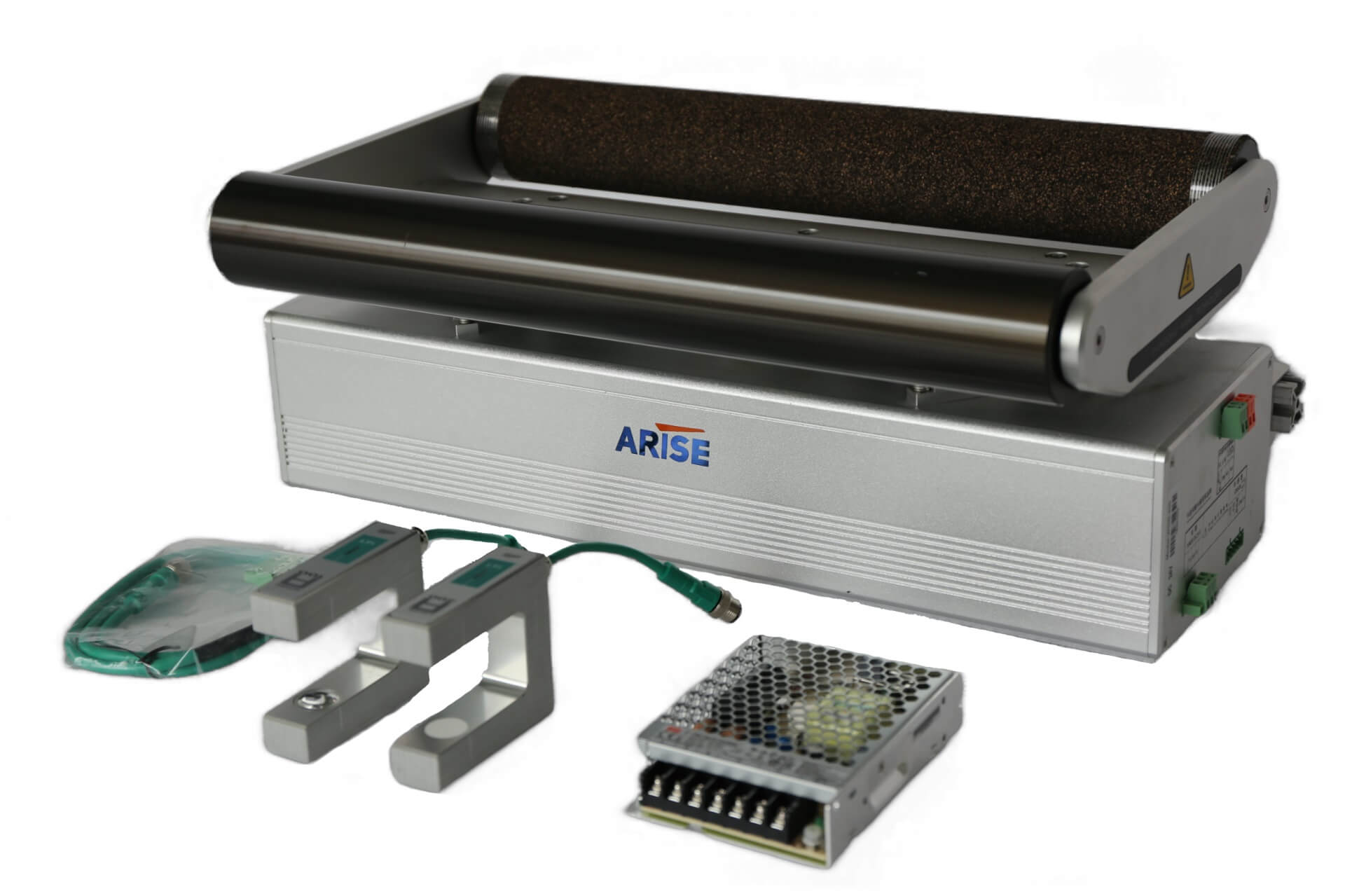

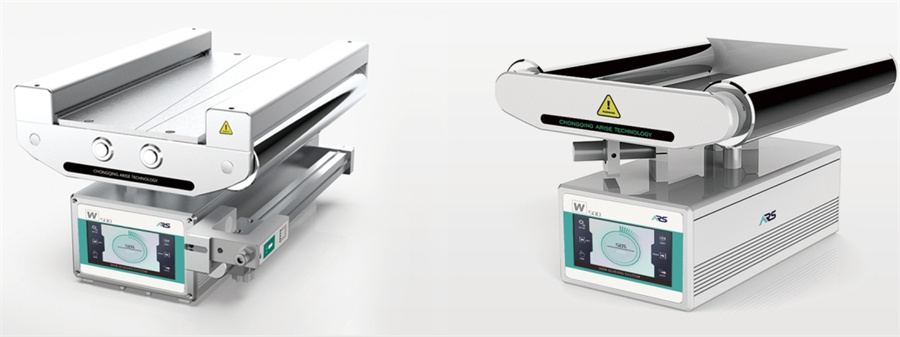

The W500 All-in-one web guiding system is a high-performance solution featuring full touch screen operation. Specifically designed for tracking material edges, lines, and contrast, it excels in automatic web guiding during material movement. Utilizing ultrasonic, infrared, or CCD sensors for signal detection, it calculates material offsets. Based on this data, servo motors and encoder feedback are precisely controlled to correct the material offset. Primarily used in industries such as lithium battery and labeling, it ensures accurate and efficient web guiding processes.

Models: W500

Brand: ARISE

Why Choose Arise Web Guiding System

The Arise web guiding system effectively manages the positional deviation of coil materials during conveyance in the production line. Offering automatic detection, tracking, and adjustment functionalities, this machine ensures precise alignment of marking lines, paper edges, film, adhesive tape, aluminum foil, and other materials, thus promoting orderly winding and slitting processes.

The Arise web guide system excels in aligning multi-layer materials, with its edge guiding system adept at tracking working material edges or printing lines with high accuracy, differential, and swing capabilities. Notably, it boasts strong anti-interference features suitable for demanding work environments, alongside high reliability and an extended service life.

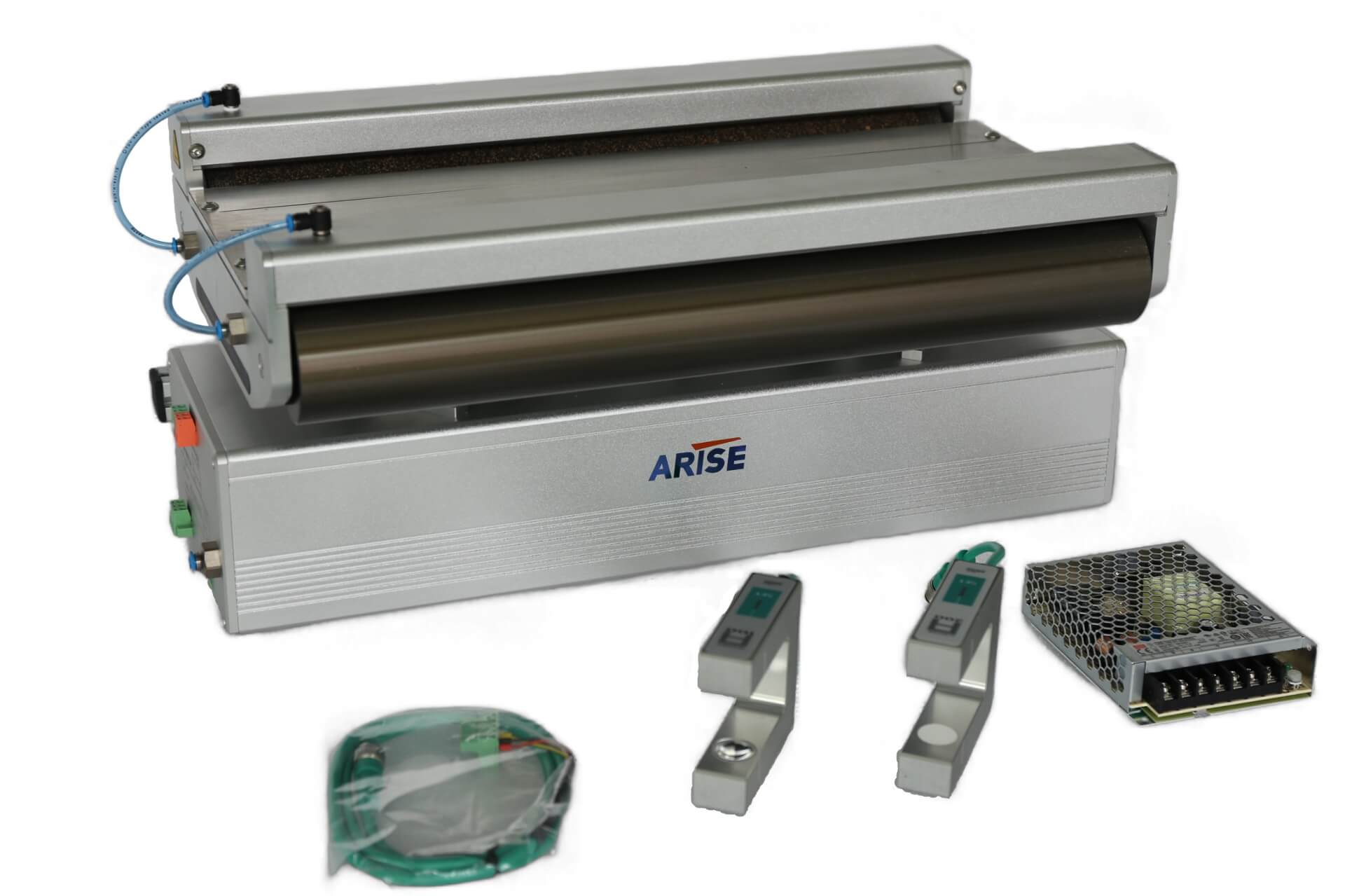

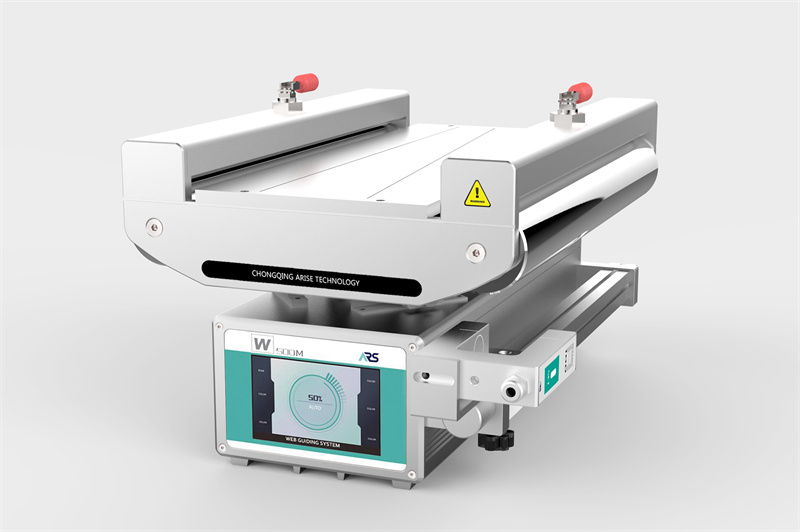

Web Guide System with Splice Table

W500 type web guide system with splice table features a manual automatic paper pressing platform to simplify material replacement. Specifically designed for tracking material edges, tracking lines, and material cutting, it is primarily used in the label, flexo printing, and paper bag industries.

Introduction Videos of Arise Web Guiding System

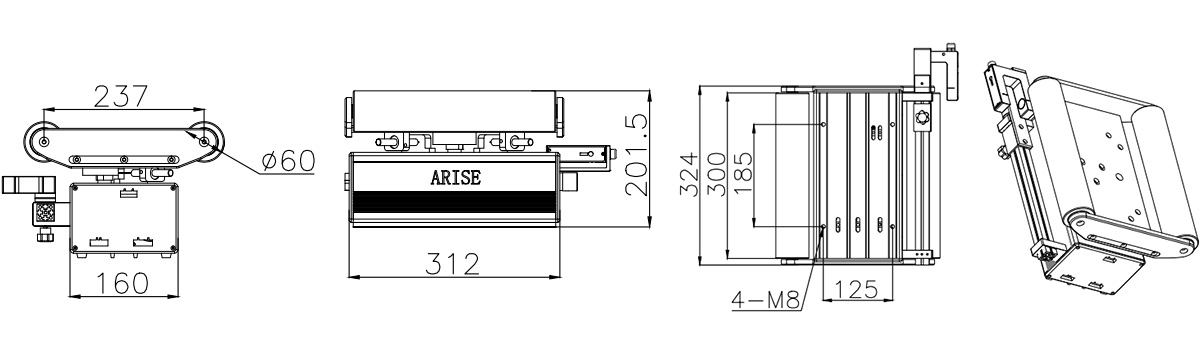

Dimensional Parameter of Arise Web Guiding System

| Precision | <±0.1mm(Depends on material) |

| Error frequency | Maximum 8Hz |

| Rated adjustment stroke LU 160mm/200mm | ±15mm |

| Rated adjustment stroke LU 250mm/300mm | ±20mm |

| Rated adjustment speed on discharge roller | 100mm/s |

| Material tension NB160/200mm | Maximum 200N |

| Material tension NB/250/300/350/400/450mm | Maximum 300N |

| Roller diameter | 40/60/80/100mm |

| Ambient temperature | +5℃ ~+55℃ |

| Relative air humidity | 15~95%(no-condensing) |

| Rated operation voltage | 24VDC |

| Rated range | 20~28VDC(fluctuated) |

| Rated range in use | 100~240V,50/60Hz |

| Current consumption | Maximum 4.5ADC |

| Interface | External manual /automatic |

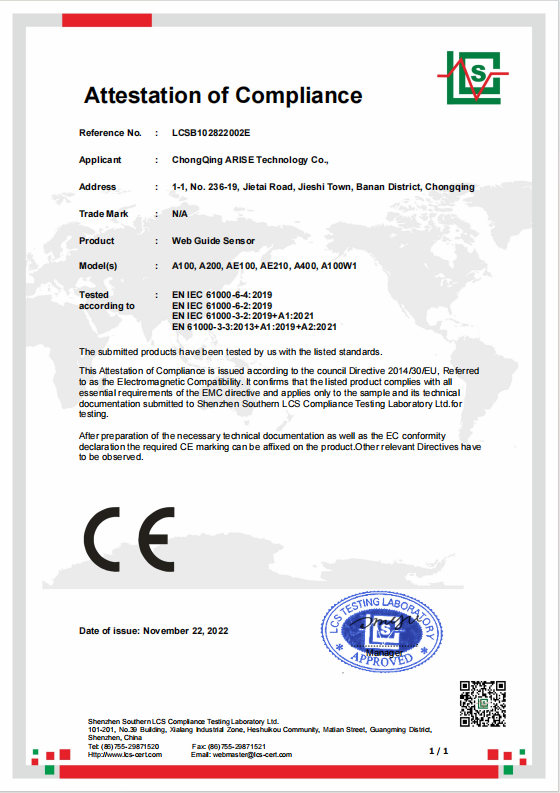

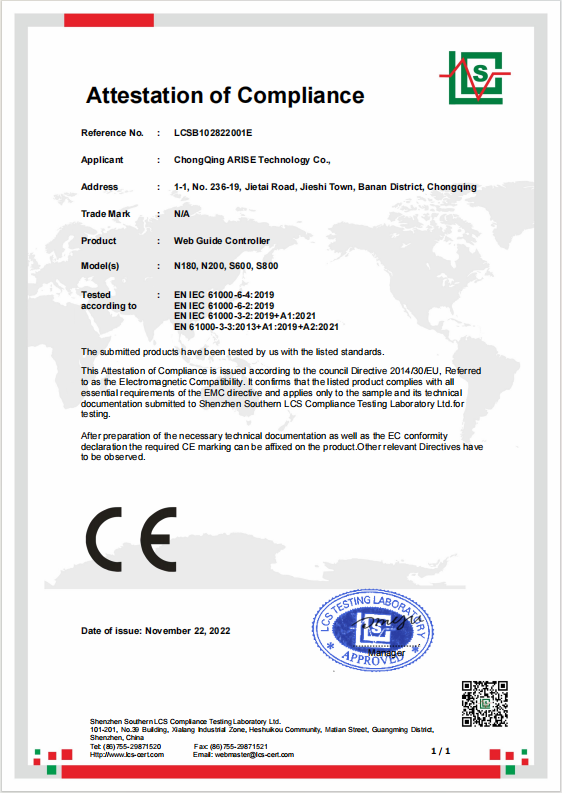

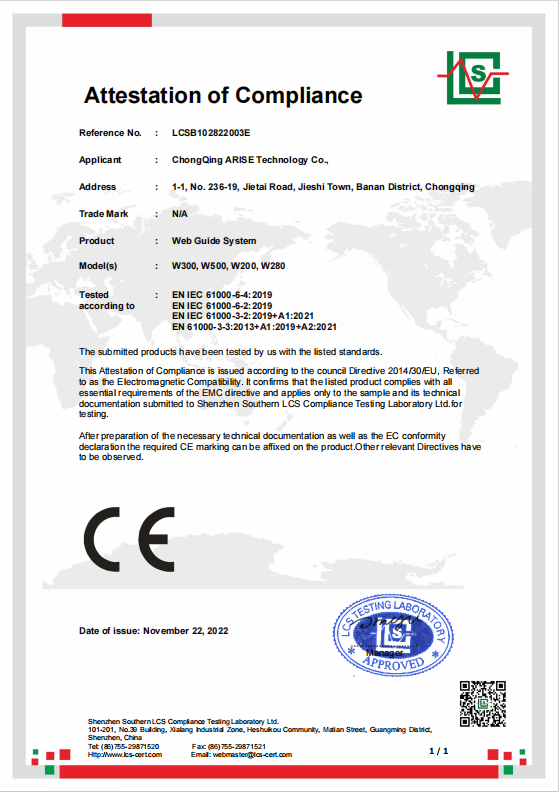

| Certification | Meet the CE standard |

| Protection grade | IP54 |

Features of Arise Web Guiding System

- Single-piece design: securely sealed and compact

- Self-clamping, replacing materials conveniently

- Brushless servo motor drive ensures maintenance-free operation.

- Compatible with various sensors including photoelectric, infrared, ultrasonic, and CCD

- Incorporates a variable PI adjustment algorithm for high precision and fast response, minimizing errors

- Equipped with precision ball screws for accurate positioning

- User-friendly interface facilitates fast and effortless operation

- Features an attractive appearance with aluminum alloy finishing and surface sandblasting oxidation

- Offers flexible installation options: can be integrated, separated, or installed at any angle

How Web Guiding System Works

The web guide machine directs the sensor to emit either infrared or ultrasonic waves to monitor the coil’s operation, transmitting the data to the web guiding controller. Upon detecting any positional deviation, the guide controller executes preset commands, prompting the drive system to adjust and correct the web’s position accordingly.

The web guide control system consists of four integral components: a controller, a web guide sensor, an electric drive, and a web guide mechanism, operating within a closed-loop control system. The sensor accurately detects the coil’s edge position, measuring the disparity between the actual and desired positions and translating it into a proportional voltage signal. This signal is then transmitted to the controller, where it undergoes amplification and calibration. Subsequently, the controller sends the processed signal to the electric driver, which in turn commands the web guide mechanism to adjust the coil’s position based on the signal’s magnitude, guiding it toward the predetermined set position.

For more professional knowledge, please visit the article page of web edge guiding system

Working Videos of Web Guiding System

The working videos showcase the operational functionality of advanced web guide systems used in various industrial applications. During manufacturing processes, these systems ensure precise alignment and control of continuous material webs, such as paper, film, or textiles. The videos illustrate how sensors detect web misalignment and how actuators automatically correct the web position in real-time. Viewers can observe different types of web guiding mechanisms, including edge guiding, center guiding, and line guiding, demonstrating their efficiency in maintaining consistent web alignment.

Application Videos of Web Guiding System

The application videos provide an in-depth look at how web guide systems are utilized across various industries. Viewers will see real-world examples of how web guiding equipment enhance production efficiency by ensuring precise alignment and control of continuous material webs. The videos highlight diverse applications, such as the paper manufacturing industry, packaging industry, etc, showing how web guiding systems minimize material waste, improve product quality, and optimize workflow.

How to Operate Web Guiding System

| Step | Action | Details |

| 1 | Servo Motor Self-Learning | 1. Start the machine in manual mode. 2. Touch “System Parameters Setting Switch Key” to access system parameters. 3. Click the “Automatic Stroke Identification Button” to start learning. 4. The motor runs back and forth to learn load and stroke, achieving optimal working state. 5. After completion, the controller returns to “manual” mode. |

| 2 | Manual State Operation | 1. Press the “Left” key to move left, the “Right” key to move right. 2. If the direction is opposite, enter “System Parameter Setting” and click “Motor Set Button” to change the hand direction. 3. Press the “Exit Setting Button” to quit. |

| 3 | Automatic Correction | 1. Switch to the “Automatic Correction” state. 2. If the direction is opposite, switch to the “Manual Correction” state and adjust the “Set Automatic State Motor Polarity” to switch the motor direction. |

| 4 | Manual Correction Adjustment | 1. Ensure the correction system runs normally. 2. Enter “System Parameters” via “System Parameter Setting Master Interface” to adjust corresponding parameters. Avoid setting sensitivity too high or too low. |

| 5 | Positive Sensor Effect Calibration (A100 Infrared Sensor) | Note: For materials that are difficult to identify, perform material correction for best effect. 1. Press and hold “SET” button until the sensor light blinks. 2. Place material in the middle of the sensor, covering the circular light-transmitting sheet. 3. Release the button once the key light stops flashing to complete calibration. |

Custom Roller Length in Web Guiding System with Splice Table

Customized roller length in the W500 web guide system with a splice table allows for tailored adjustments to meet specific application requirements. By customizing the length, the system can accommodate various material widths, enhancing precision and efficiency in guiding and correcting the web. This flexibility is essential for optimizing performance across different industries, such as printing, packaging, and textiles, ensuring that the web guide system aligns perfectly with the production needs and constraints.

| W500 splice table | Mounting hole size | Roller length | Box length | Roller frame length |

| 250 | 185mm | 250 mm | 312mm | 274mm |

| 300 | 185mm | 300mm | 312mm | 324mm |

| 350 | 285mm | 350mm | 412mm | 374mm |

| 400 | 285mm | 400 mm | 412mm | 424mm |

| 450 | 385mm | 450mm | 512mm | 474mm |

| 500 | 385 mm | 550 mm | 512mm | 524mm |

| 600 | 485 mm | 600 mm | 612mm | 624mm |

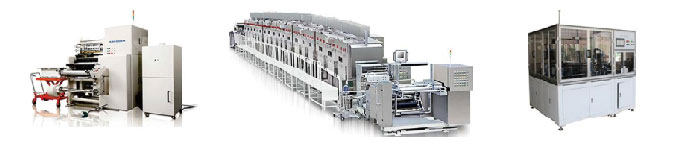

Applications of Web Guiding System

Web guide systems are widely used in printing, packaging, textile manufacturing, plastic film production, and other industries where maintaining accurate web positioning is crucial. Web guiding technology minimizes material waste, enhances product quality, and optimizes workflow by automatically correcting any deviations in the web’s path.

Printing and Flexible Packaging industry

Solvent-free laminating machine, bag making machine, inspection machine, labeling machine, etc.

Battery industry

Lithium voltage film machine, lithium battery slitting machine, lithium battery replacement machine, battery lamination machine, etc.

Film industry

Film blowing machine, replacement machine, film slitting machine, film casting machine, etc.

Tire industry

Fiber steel wire calender, tire building machine, steel cord cutting machine, production line, etc.