Product Articles

How Web Guide Controllers Enable Customization in Evolving Packaging Trends?

In the packaging production line, small batch production, more SKUs, mixed materials, and stricter tolerances have gradually become the norm. From a marketing perspective, customization sounds great, but on the…

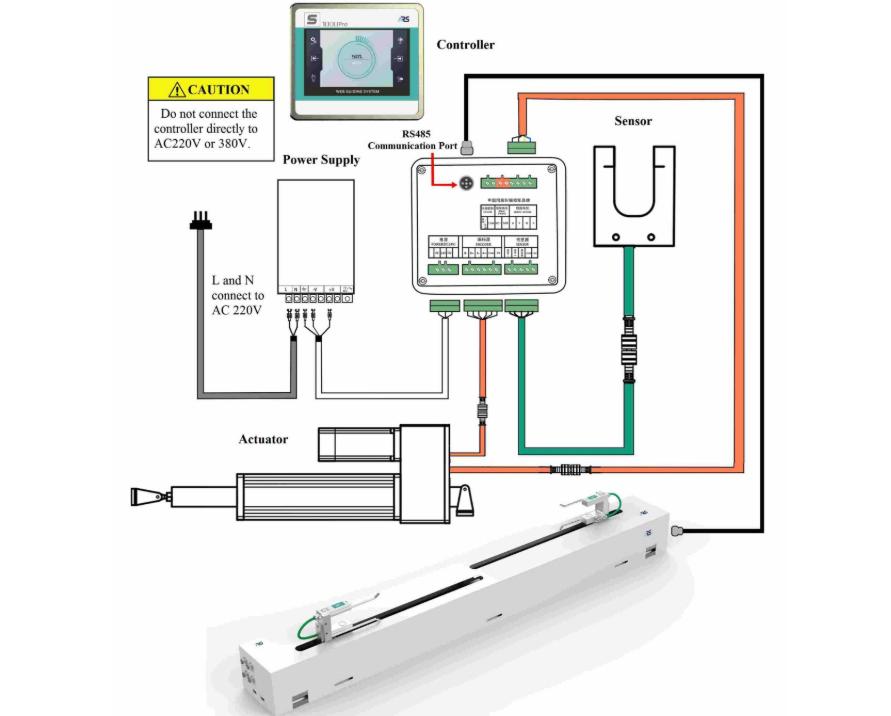

What Factors Affect the Accuracy of Web Guiding Systems?

When people discuss the accuracy of web guiding systems, they often quote a single number, such as “±0.1 mm.” In the real world, accuracy is not defined by any single component…

Integrating Label Inspection System Without Modifying Equipment

For many manufacturers, adding a label inspection system is not a technical challenge—it’s an integration risk. The packaging line is already running. Machines are validated. Any mechanical or PLC change raises…

Web Guide System Maintenance: A Preventive Checklist to Avoid Unplanned Downtime

When your web guide system breaks down, your entire production line comes to a halt. The aftermath is not only silence but also lost income, materials that have to be thrown away,…

Why Does My Web Guiding System Fail at High Tension Levels?

Increasing web tension appears to be an easy answer in many production lines. In theory, higher tension can help improve flatness, eliminate wrinkles, and even stabilize the process. However, engineers…

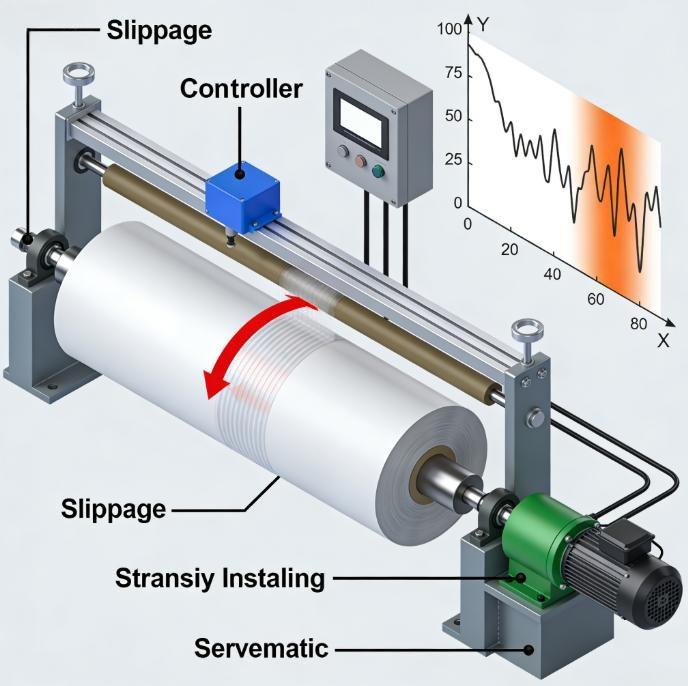

How to Prevent Web Slippage in Tension Control Systems?

Web slippage is frequently the main reason for the lack of stability in roll-to-roll tension control systems, resulting in unstable tension, poor register accuracy, and high material waste. It usually…

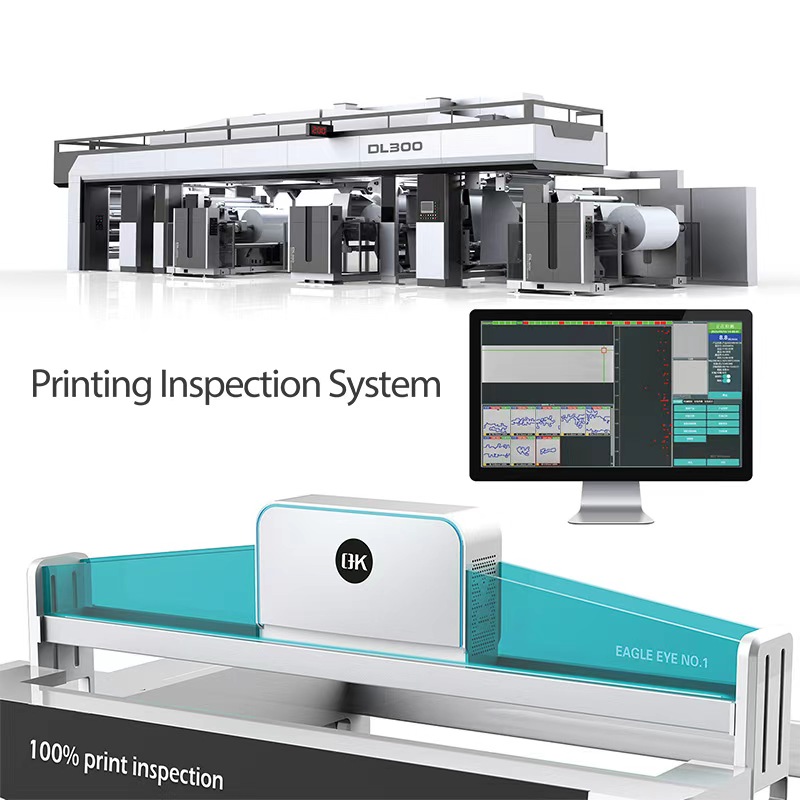

100% Inspection System: Actual Installation Steps and Precautions

In the production of printing, a missing character, a tiny color shift, or a registration error may happen from time to time and go undetected by either manual checks or…

How to Reduce Printing Defects in High-Speed Web Production?

In the printing and converting industries that rely heavily on the web, increased production speed is mostly considered a shortcut to the desired outcome of higher output and lower unit cost…

Traditional Sampling Inspection vs. 100% Print Inspection: What’s the Real Gap?

While traditional sampling inspections are slow and ineffective at keeping pace with modern-day production scanning, printing quality standards are rapidly increasing. Common problems being faced are missed defects, material loss,…

How Web Inspection Systems Work for Ensuring Label Quality

In the packaging and labeling industry, it is very important to maintain a certain quality standard. Quality standards are important because labels are more than just identifying a brand, they…