User-friendly Interfaces in Print Inspection Systems

Print inspection systems are essential tools for detecting flaws as, ensuring color consistency and maintaining production standards. One of the most important aspects that determines the the effectiveness of these systems is the design of their user interfaces. User-friendly interface is crucial in streamlining the operation process while reducing errors and improving overall productivity.

Table of Contents

Why User-friendly Interfaces are Important in Print Inspection Systems

Enhancing Operational Efficiency

User-friendly interfaces speed up the process by allowing workers to access essential functions swiftly. The intuitive controls can cut down the time spent in navigating menus and analyzing system outputs, allowing users to concentrate on tasks of inspection. Through simplifying complicated processes, these interfaces reduce errors and ensure uniform printing quality.

Reducing Training Time and Costs

The process of training for new employees can be lengthy and expensive, particularly when it comes to complex inspection systems. A design that is clear and ease allows users to improve their skills quicker. The step-by-step instructions with clear visual prompts and an intuitive navigation eliminate the need for long-running training sessions, which saves time and money for printing businesses.

Improving Accuracy and Quality Control

An intuitive interface can improve the precision of defects detection. Highlights in real-time, alerts in real-time and clear feedback guarantee that the operators are able to spot issues quickly. This enhances the quality of control by reducing oversight as well as ensuring only items conforming to standards can proceed into the next phase of production.

Supporting Data-driven Decisions

Modern printing systems produce huge amounts of information. The user-friendly interface makes it easy to interpret and access the information. Managers and operators can track the production process, identify issues, and make informed decisions to improve productivity and quality of the product.

Enhancing Operator Experience

A simple, user-friendly interface can reduce the fatigue of users and frustrates. In making interactions with the system easy and easy to understand, users can perform their work more easily and with confidence. This improves productivity, but also creates a an improved and safer workplace.

Key Features of Effective User-friendly Interfaces in Print Inspection Systems

The user-friendly interfaces are designed to allow operators to work with the printing inspection system effectively , reducing errors and enhancing overall productivity.

1. Intuitive Navigation

A user-friendly interface emphasizes easy navigation, which makes it simple users to find features and settings. Menus, icons and controls are organized in logical ways and users are able to swiftly find the most important equipment and modify the parameters of inspection. Through reducing complexity, simple navigation reduces the need for learning and allows operators to concentrate on tasks of inspection instead of operating the system.

2. Real-time Visual Feedback

Visual feedback is an essential element for monitoring the print quality during high-speed printing production. Effective interfaces give real-time notifications and highlight any issues with clearly colored indicators. This instant feedback allows the operator to spot and rectify problems immediately, thus reducing the possibility of defective products being pushed through the manufacturing line.

3. Customizable Dashboards

Different workflows and user preferences demand flexible and adaptable interfaces. Customized dashboards allow users to customize the presentation to display the most relevant information for their specific job. By providing crucial indicators and inspection results at the look, dashboards boost efficiency and facilitate faster decision-making.

4. Step-by-step Guidance and Tutorials

Even experienced operators can benefit from the help features that are integrated into the interface. Instructions that are step-by-step and interactive assist users in performing difficult inspection tasks with precision and ensure consistent quality while decreasing human errors. This feature is especially useful in the training of new operators, thereby saving time and money.

5. Remote Monitoring and Control

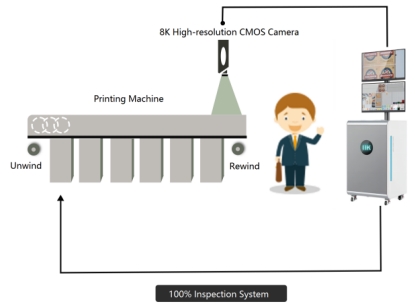

Advanced 100% print inspection systems often provide remote monitoring, allowing quality managers or supervisors to monitor production from afar. Remote access permits timely intervention, better coordination and data-driven decision-making which all help improve productivity and control of quality.

6. Integration with Data Analytics

Effective interfaces work seamlessly to data analysis tools and provide both historical and live production data in a readable format. Visualizations of the trends in defects along with process efficiency and quality metrics allow managers and operators to improve processes, reduce waste, and constantly improve standards of production.

Best Practices for Operating Print Inspection Systems with User-friendly Interfaces

| Best Practice | Description |

| Understand the Interface | Spend time getting familiar with the controls of your system menus, controls, and navigation to minimize errors in operation. |

| Monitor Data Regularly | Examine production data and past trends to make educated decisions and improve processes. |

| Maintain Consistency | Standardize the inspection process using an interface that ensures consistent quality throughout shifts and between operators. |

| Perform Routine Updates | Make sure that your software and interface components are current to take advantage of the most recent features and enhancements. |

| Provide Operator Feedback | Send usability concerns or suggestions to improve the functionality of interfaces or overall performance. |

Future Outlook of User-friendly Interfaces in Print Inspection System

As the printing industry continues to evolve, the role of print inspection system in maintaining quality and efficiency will become increasingly important. User-friendly interfaces are predicted to become even more intelligent, adaptive, and integral to the efficiency of printing quality inspection systems.

1. Integration of Artificial Intelligence

Future user-friendly interfaces within printing inspection systems is dependent on AI integration (AI). AI-powered interfaces can not only detect defects on their own, but they will can also anticipate possible quality issues prior to they happen. Through providing relevant information in real-time, these technologies will enable operators to take faster, better well-informed decisions, which will reduce costs and boosting overall quality of production.

2. Adaptive and Personalized Interfaces

Interfaces will be able to adapt to the individual preferences of users as well as workflow habits. Customized dashboards and dynamic features will guarantee that every user is presented with the information that is that is most relevant for their task. The flexibility will help streamline processes, decrease cognitive burden and improve the efficiency of operators particularly when working in production settings with high speeds.

3. Augmented Reality Support

Augmented Reality (AR) is poised to change the way in which users interact with printing inspection systems. AR overlays are able to guide operators through difficult inspection tasks, highlighting visually the issues and suggestions for improvements. This approach to immersive technology will make training, decrease errors, and improve overall quality process for assurance.

4. Voice and Gesture Control

Hands-free operation is expected to become an actuality in the future interfaces. Gesture commands and voice commands will enable users to interact with the web vision inspection systems during printing operations, increasing the safety and efficiency of environments where speed and accuracy are essential.

5. Enhanced Data Visualization and Analytics

Future interfaces will be focused on providing more rich, informative visualization of data. Interactive screens will give managers and operators with instant access to the past trends, defects patterns, as well as real-time production metrics. Advanced analytics will aid in the use of predictive maintenance, continuous process improvement, and more intelligent decisions.

Summary

The user-friendly interface is one of the most important elements of modern print inspection systems. By focusing on intuitive design, visual clarity and interactive functionality, manufacturers can significantly improve production efficiency, reduce errors, and ensure consistent product quality. While technology is continuing to advance, with the integration of AI and adaptive controls, it promises an even more seamless and efficient printing inspection operation experience.