What are Key Features and Technologies Powering Printing Quality Inspection Systems

Efficiency and precision are critical in the fast-paced world of modern manufacturing. This is most visible in the printing industry, where the need for high-speed output meets the need for flawless quality. Printing quality inspection systems have revolutionized the landscape of printing quality assurance. In this article, we explore the key features and technologies of printing quality inspection systems and the profound impact they have on ensuring top-notch printing quality at unparalleled speeds.

Key Features and Technologies of Printing Quality Inspection Systems

1. Advanced Vision Systems

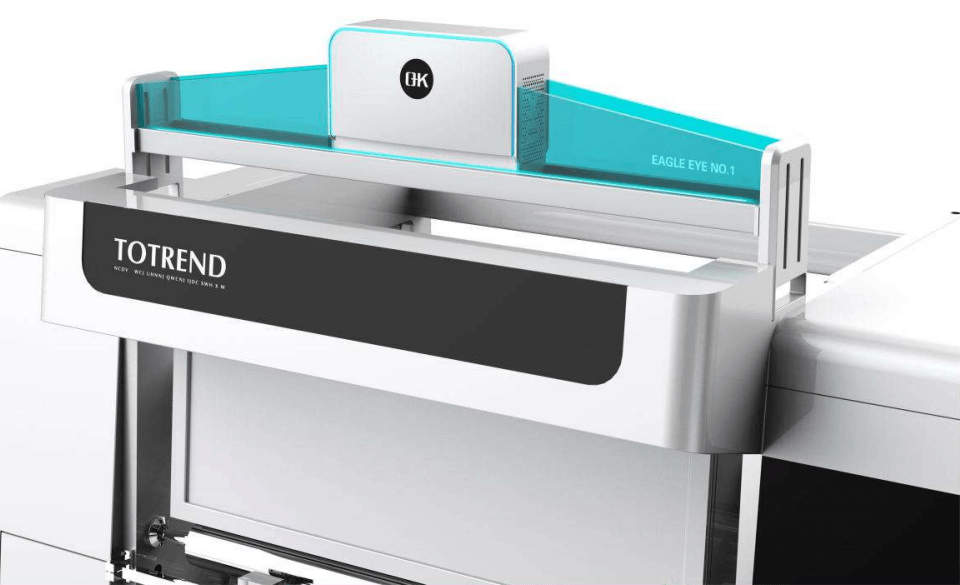

High-Resolution Cameras: The advanced web inspection vision systems equipped with high-resolution cameras are the foundation of printing quality inspection systems. These cameras record photos at breakneck speeds, allowing each detail of the printed material to be inspected.

Image Recognition Algorithms: Modern image recognition algorithms process collected photos in real time. These algorithms are intended to recognize and analyze many characteristics of print, such as text and pictures, as well as color and registration.

2. Real-Time Inspection

Continuous Monitoring: One of the standout features is the ability to perform real-time inspection as the printed material moves through the production line. Continuous monitoring ensures that any defects or deviations from quality standards are identified instantly.

Instantaneous Feedback Loop: The real-time nature of these systems establishes an instantaneous feedback loop. Operators can receive prompt notifications about any detected issues, enabling swift corrective actions and minimizing the risk of producing defective prints.

3. Defect Detection and Classification

Comprehensive Defect Identification: Misprints, color variations, streaks, and missing pieces are all easily detected by printing quality inspection systems. The capacity to discover flaws completely ensures a thorough quality check.

Defect Classification: These systems go beyond detection by classifying defects based on their nature. Whether it’s a registration error or an issue with color consistency, the system categorizes defects, facilitating targeted corrective measures.

4. Integration with Printing Equipment

Compatibility with Various Printing Technologies: Printing quality inspection systems are designed to work in tandem with various types of printing equipment with different technologies. These systems can be converted to current production lines for flexographic, offset, or digital printing.

Synchronization with Printing Speeds: The integration ensures coordination with the printing equipment’s pace. This is critical for ensuring inspection accuracy, especially in high-speed printing environments where rapid conveyance of printed material is the norm.

5. Automated Data Analysis

Smart Software Solutions: The inspection systems employ intelligent software solutions for automated data analysis. These solutions use algorithms to interpret the collected data, identify defects, and generate comprehensive reports.

Data Visualization: Automated data analysis includes advanced data visualization features that present the inspection results in a clear and understandable format. Operators can quickly assess the quality status of the printed material and take corrective actions as needed.

6. Multi-Sensor Technology

Diversity in Inspection Parameters: Some printing quality inspection systems use multi-sensor technology to measure multiple parameters at the same time. This can comprise color, thickness, and surface quality, giving a comprehensive picture of print quality.

Comprehensive Quality Assessment: Multi-sensor technology allows for a more comprehensive quality inspection by evaluating several aspects of the print at the same time. This is especially useful for applications with high quality standards.

7. Communication and Connectivity

Integration with Plant Control Systems: printing quality inspection systems often feature communication capabilities for seamless integration with plant control systems. This integration enables centralized monitoring and control, contributing to overall production efficiency.

Connectivity for Remote Monitoring: In an era of Industry 4.0, these systems may offer connectivity options for remote monitoring. Operators and quality control personnel can access real-time data and inspection results from anywhere, enhancing flexibility in managing print quality.

8. Artificial Intelligence (AI) and Machine Learning (ML)

Pattern Recognition: Some advanced systems incorporate AI and ML for pattern recognition. This allows the system to adapt and learn from various printing scenarios, improving its ability to identify subtle defects or deviations.

Predictive Maintenance: AI and ML algorithms can be applied for predictive maintenance. The system can analyze historical data to predict when components might require maintenance, minimizing downtime and ensuring continuous operation.

Future Technical Advancements of Printing Quality Inspection Systems

As technology continues to advance, printing quality inspection systems are poised for further refinement and integration with other smart manufacturing technologies. The incorporation of artificial intelligence and machine learning algorithms holds the promise of even more sophisticated defect detection and analysis, further elevating the standards of print quality in high-speed production environments.

Conclusion

Printing quality inspection systems offer a paradigm shift in the printing industry’s quality assurance. Their ability to connect easily with high-speed printing lines, combined with real-time inspection capabilities, makes them important tools for manufacturers seeking to balance speed and precision. As these technologies evolve, the future of high-speed printing appears brighter than ever, promising not only faster output but also a new level of unparalleled print quality.