What Is Web Tension Controller

The coil business is reliant on web tension control, particularly for uses using continuous webs or strips of materials like paper, film, plastic, or metal. The tension on the web throughout the production process is measured and controlled by a web tension controller. This procedure is essential to ensuring that the final product satisfies the necessary requirements.

The Importance of Web Tension Controller in Coil Industry

Consistent Quality

For the production process to produce products of consistently high quality, web tension must be maintained consistently. Any differences in web tension can result in flaws or consistency issues in the final output. For instance, the material may stretch if the web tension is too high, producing in a deformed product. The material may wrinkle if the tension is too low, leading to flaws.

Improved Productivity

Reduced waste generated during production thanks to web tension controller can increase productivity. The likelihood of flaws can be decreased, and the requirement for rework or scrap can be minimized, with proper tension control. Higher yields and more effective production may result from this.

Equipment Protection

A web tension controller might aid in preventing equipment damage as well. Equipment used to handle webs, like spindles or rollers, may become damaged if web tension is not properly managed. The need for repairs or replacements can be minimized and this damage can be prevented with proper tension control.

Factors Affecting Web Tension Controller

Web Material

The web tension can be impacted by the kind and characteristics of the web material. The amount of tension necessary to maintain the correct web tension might vary depending on the elasticity, stiffness, and friction properties of the material being used.

Web Speed

The web tension can be impacted by the kind and characteristics of the web material. The amount of tension necessary to maintain the correct web tension might vary depending on the elasticity, stiffness, and friction properties of the material being used.

Roll Diameter

The web tension may vary depending on the roll’s diameter. In order to maintain the desired tension, the web tension must increase as the roll diameter does.

Web Width

The web tension may vary depending on the web’s breadth. To keep the desired tension, wider webs need greater tension.

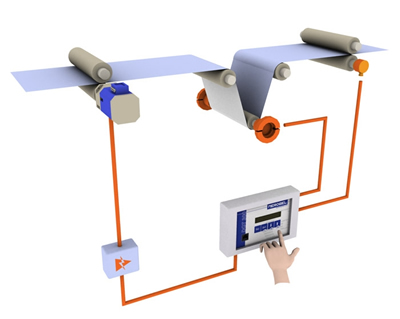

How Web Tension Controllers Work

Web tension controllers monitor the tension of the material as it moves through the manufacturing process using sensors. The sensor sends a signal to the controller, which compares the actual tension to the desired tension and adjusts as needed.

The tension can be adjusted by varying the web speed, applying additional tension via brakes or clutches, or adjusting the torque of the drive motor. The tension can also be adjusted based on other variables, such as changes in the material’s thickness or width.

A closed-loop control system is typically used by web tension controllers, which means that the controller continuously monitors the tension and makes real-time adjustments to maintain a consistent tension level. This helps to ensure that the material is processed correctly and to the desired quality standards.

Types of Web Tension Controller

Closed-loop

Closed-loop controllers measure web tension and adjust it as needed using feedback sensors. The controller compares the current tension to the desired tension and adjusts the brake or clutch to keep the desired tension. Closed-loop controllers are extremely accurate and can maintain precise tension control even at high speeds.

Open-loop

Open-loop controllers use a set-point to adjust the tension of the brake or clutch. They do not, however, use feedback to adjust the tension. They are less accurate than closed-loop controllers and are typically used in applications with less stringent web tension requirements.

Manual

In applications where web tension is not critical, manual controllers are used. To adjust the tension, these controllers use a hand-operated brake or clutch. Manual controllers are inexpensive, but they are not appropriate for high-speed or precision applications.

Advantages of Web Tension Controllers

1. Increasing Productivity

By reducing downtime and waste, web tension controllers can help to increase productivity. The process can run more smoothly and efficiently if the tension level is kept constant.

2.Improving Quality

Web tension controllers can help to improve the final product’s quality by ensuring that it is manufactured to the desired specifications. This can help to reduce rejects while also increasing customer satisfaction.

3.Cost Savings

Web tension controllers can help you save money on waste, downtime, and rejected products. This can aid in increasing profitability and lowering overall processing costs.

4.Flexibility

Web tension controllers are adaptable to a wide range of materials and processing conditions. As a result, they are highly adaptable to various production environments.

5.Safety

Web tension controllers can help to improve workplace safety by lowering the risk of accidents and injuries caused by manual tension control methods.

Summary

Web tension controllers are an important part of the coil industry because they help to ensure consistent quality, increase productivity, and protect equipment from damage. Coil manufacturers can achieve consistent quality and efficient production by selecting the appropriate web tension controller.