Traditional Sampling Inspection vs. 100% Print Inspection: What’s the Real Gap?

While traditional sampling inspections are slow and ineffective at keeping pace with modern-day production scanning, printing quality standards are rapidly increasing. Common problems being faced are missed defects, material loss, and inconsistent results. In this article, we will clarify the differences between sampling inspection and 100%printing inspection, and we will explain the reasons for the high adoption of advanced printing inspection systems for consistent and reliable quality.

Table of Contents

What Is Traditional Sampling Inspection & Why It Fails in Modern Printing?

Quality control in sampling inspection still involves a printed sample for every nth interval to gauge whether a print run meets customer specifications. While this may have been a reasonable approach when print speeds and production stability were lower, today’s printing environment is exposed to major challenges. Defects are easily introduced and spread rapidly due to high-speed printing, short print run lengths, and increasing SKU variation.

The problems with this approach are difficult to manage. First and foremost is print run DEFECTS. Most of the time, under this approach, you are looking at less than 1% of the total output. This leaves the other 99% entirely unassessed for quality. Bad things happen to print quality randomly (streaks, ink splashes, registration drift, and other tension-related problems) in between the sample intervals—this is a given in printing. Even the most experienced operators run into collisions with fatigue, low lighting, and heavy work jars, which reduce the quality of the print samples.

The business case for sampling quality inspection is severely marginalized for growing markets like packaging, pharmaceuticals, and FMCG. The consequences of relying on sampling for final quality inspections are material waste, reprints, slowdowns, and ultimately damage to the customer relationship. There is no other way to say it—sampling inspection is not a viable approach anymore in high-speed printing.

What Is 100% Print Inspection and How It Works on the Production Line?

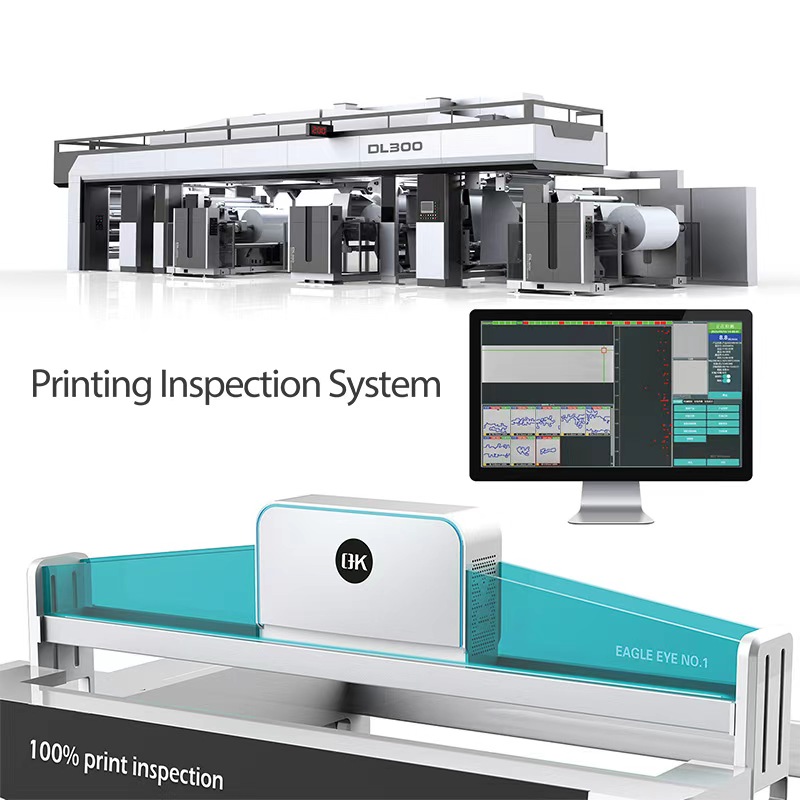

This is where 100% print inspection shifts the model of quality control. Quality control is no longer sampling. The 100% print inspection system watches every repeat and every meter of the web on the fly. Using high-resolution cameras coupled with stable LED lighting and sophisticated image processing, the print system continuously scans the print against a master image.

Missing elements, ink, changing colors, streaks, dirt, registration, or any number of imperfections are identified. Operators are notified, and problems can be addressed before significant waste is processed. Many systems also scan the roll to produce defect maps, so downstream processing equipment can automatically skip over bad spots.

Since the entire roll is scanned at production speed, print inspection is able to eliminate blind spots, providing complete, uninterrupted coverage of the web. The benefit is a reliable, automated system that can monitor high-speed printing with far more confidence than random sampling.

Where Traditional Sampling Fails, and 100% Print Inspection Solves the Problem

Traditional sampling inspections leave colossal blind spots, as they only look at a small fraction of the output, and defects can certainly get overlooked. This leads to a waste of time, as work may get reprinted, customers could get angry, and defects can get noticed. No matter how experienced, humans will always have limitations due to fatigue, attention spans, and subjective judgments. Defects missed are only amplified when printed runs are short, and jobs get changed frequently.

100% print inspection helps cover these weaknesses, as they are always able to look over the entire production line. Here are a few of the major benefits of this:

- Total Coverage: No blind spots, as every meter of the web is completely scanned.

- Real-Time Alerting: Defects, such as streaks, ink voids, misregistration, voids, and alterations in color are flagged in real time.

- Consistent Control: Operator fatigue and subjectivity are eliminated by automation.

- Roll mapping and defect logging: Accurate identification and correction are a consequence of these two features, as defect logging helps precisely pinpoint where the problem is found.

- Reduction of Waste: No defective materials can proceed down the line, as they are pulled out of the production line due to the real-time alerts.

Ultimately, while sampling runs are only reactive, 100% print inspections are proactive on all runs, providing a modern solution to all quality control issues in the industry.

100% Print Inspection vs. Sampling Inspection: Side-by-Side Comparison

Comparing traditional sampling inspection to 100% print inspection underlines why modern printing is moving to automated solutions. The differences are not about technology; they are about quality, efficiency, and customer satisfaction.

| Factor | Traditional Sampling Inspection | 100% Print Inspection |

| Coverage | Checks only selected samples (<1% of output) | Monitors 100% of the printed web in real time |

| Defect Detection | Misses defects between samples | Detects streaks, color shifts, registration errors, and contamination instantly |

| Consistency | Depends on operator skill and alertness | Fully automated, repeatable, and reliable |

| Response Time | Delays in identifying issues | Immediate alerts for corrective action |

| Labor Requirement | High – requires trained operators | Low – system handles continuous monitoring |

| Waste Reduction | Limited; defects may propagate unnoticed | Significant; real-time intervention prevents scrap |

| Traceability & Reporting | Manual records, often incomplete | Automatic logs, defect maps, and quality reports |

This comparison is well-illustrated to prove that 100% print inspection isn’t just a step up in technological capability but a sea-change in quality control, offering accuracy, speed, and reliability that sampling inspection can’t compete with.

Why More Factories Are Upgrading to 100% Print Inspection

Factories around the world are increasingly moving toward 100% print inspection in an effort to keep pace with higher quality demands, faster production speeds, and more complex job setups. The trend is driven by several tangible benefits:

- Reduced waste and rework: Real-time defect detection avoids long runs of defective material, saves time, cost.

- Consistent quality assurance: automated systems exclude human variability linked to fatigue and subjective judgment.

- Improved traceability: Detailed defect logs and roll maps provide an accurate record for compliance and customer audits.

- Greater client confidence: It becomes easier to meet even the most strict brand standards, strengthening relationships with the most demanding clients.

- Higher customer confidence: Meeting strict brand standards becomes easier, which improves relationships with demanding clients.

- Labor efficiency optimized: The operators will be free to optimize the machines instead of constantly visually inspecting them.

For modern printing operations, investment in a print inspection system is no longer discretionary but an essential ingredient in competitive advantage. At ARISE, our advanced 100% print inspection solutions deliver dependable, high-speed quality control custom to your production needs. Contact us today to learn how your factory can achieve zero-defect printing and maximize efficiency.