A Comprehensive Guide to Knowing Magnetic Powder Brake

Definition Of Magnetic Powder Brake

A magnetic powder brake is an electromagnetic device that controls the torque or speed of rotating machinery. It is a form of friction brake that transmits torque between two rotating surfaces by using a powder consisting of magnetic particles. When a magnetic field is supplied to the powder, a shear force is generated that opposes the relative motion of the surfaces, forcing the brake to engage and slow or stop the spinning machinery.

How Torque Is Transmitted Through The Brake In Magnetic Powder Brake

Torque is conveyed by magnetic particles suspended in a fluid in a magnetic particle powder brake. An electromagnetic field is applied to the powder when the brake is engaged, causing it to form chains of particles that oppose the relative motion of the two rotating surfaces. The torque imparted by the brake is related to the magnetic field strength and the amount of magnetic powder in the brake.

1. Structure of Magnetic Powder Brake

The input rotor (also known as the field rotor) and the output rotor (also known as the armature rotor) are the two primary components of a standard magnetic powder brake. A little air gap separates these two rotors. The driving shaft is connected to the input rotor, while the load is attached to the output rotor.

2. Magnetic Powder Filling:

The space between the input and output rotors is filled with a thin magnetic powder contained in a carrier fluid, which is often iron or iron-based compounds. This powder is in charge of transmitting torque.

3. Electromagnetic Coil

An electromagnetic coil surrounds the input rotor and generates a magnetic field when powered. When current travels through the coil, a magnetic field is created in the air space between the two rotors.

4. Magnetic Particle Alignment

When the magnetic field is applied by the electromagnetic coil, it causes the iron particles in the magnetic powder to align with the field lines. As a result, the magnetic particles create bridges across the air gap, connecting the input and output rotors.

5. Torque Control

The operator can precisely control the torque by regulating the input current to the electromagnetic coil. Increasing the current strengthens the magnetic field and, in turn, the torque transmitted. Decreasing the current weakens the magnetic field, reducing the transmitted torque.

6. Torque Limitation

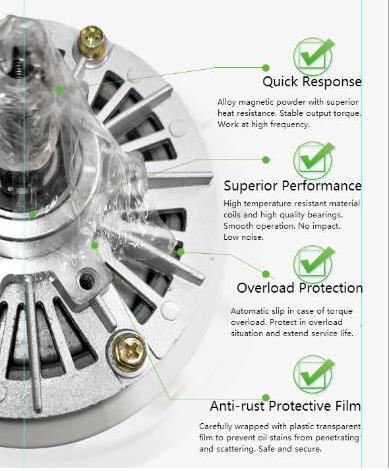

One of the advantages of magnetic powder brakes is that they can limit the maximum torque applied to the load. This feature is particularly useful in applications where overloading or sudden torque spikes need to be prevented.

7. Slip and Speed Control

Magnetic powder brakes are also capable of slip and speed control. When the input rotor (driving shaft) is rotated at a different speed than the output rotor (load), the relative motion creates a slip. By adjusting the current to the coil, the amount of slip and, consequently, the speed difference between the input and output rotors can be controlled.

Types Of Magnetic Powder Brake

Magnetic powder brakes are classified into two types: hysteresis and eddy current. Hysteresis brakes employ a powder composed of ferromagnetic particles that are attracted to one another in a magnetic field and hence impede relative motion between two surfaces. When subjected to a magnetic field, conductive particles in the powder generate eddy currents, providing a magnetic force that resists the relative motion of the two surfaces.

Wide Applications Of Magnetic Powder Brake

Printing presses, wire drawing machines, and web tension control system are all examples of where magnetic powder brakes are used. It is also used in the automotive and aerospace industries, where it is used in aircraft braking systems and dynamometers. Magnetic powder brakes have a novel application in medical imaging, where they are used to control the motion of rotating components in MRI equipment.

Maintenance And Troubleshooting Of Magnetic Powder Brake

The maintenance of magnetic particle powder brake is critical for reliable and safe operation. The following are some magnetic powder brake maintenance and troubleshooting recommendations.

Maintenance

Regular Maintenance Inspection

Inspect the brake on a regular basis for wear and damage to its components, which include the magnetic powder, stator, rotor, coil, and housing. Replace any worn or damaged components as soon as possible.

Cleaning

Regularly clean the brake to eliminate any dust, dirt, or debris that might accumulate on the braking surfaces and impair performance.

Lubrication

Lubrication is required for some magnetic powder brakes to prevent wear and friction. Use only lubricants that are compatible with the braking components.

Adjustments

Using a controller that controls the amount of current flowing through the brake, change the magnetic field intensity of the brake coil as needed.

Troubleshooting

Slipping, decreased torque capacity, and overheating are all common problems with magnetic powder brakes. Adjust the magnetic field strength, inspect for worn or damaged components, or reduce the load on the brake to troubleshoot these problems.

Development Trends of Magnetic Powder Brake

Energy from Renewable Resources

Magnetic powder clutch brake can be used to control the speed of wind turbines, thereby optimizing energy output and reducing equipment wear and tear.

Robotics

It can be used in robotic systems to control joint and limb movement, giving precise and accurate control.

Medical Science and Technology

It can be used to provide adjustable degrees of resistance or support in medical devices such as prosthetics and exoskeletons.

Aerospace

The aerospace industry is developing novel applications to control the movement of aircraft control surfaces such as flaps and rudders.