The Use of 100% Print Inspection in High-speed Printing Industries

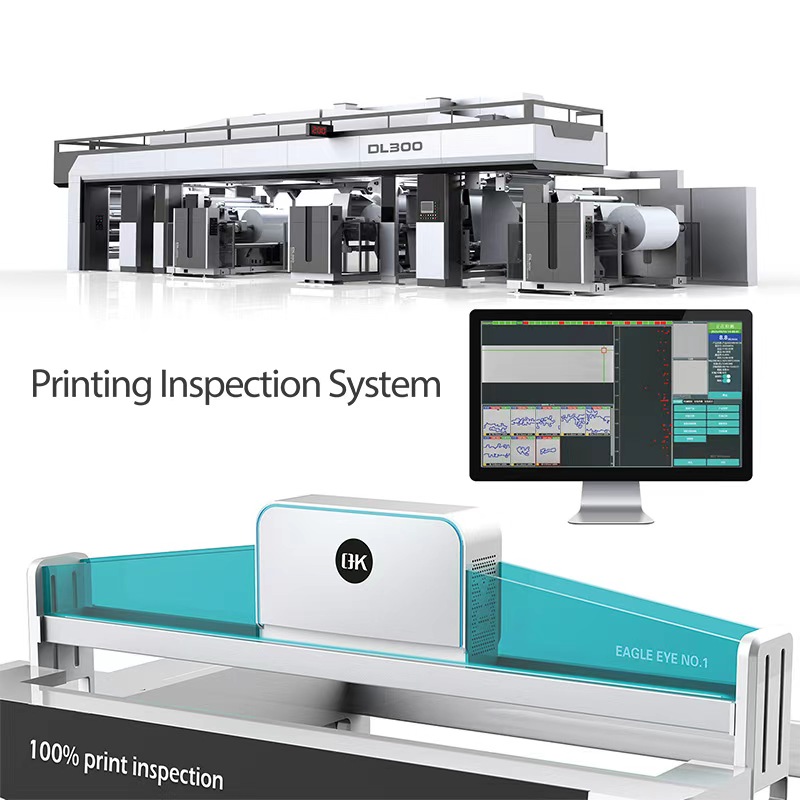

Maintaining consistent quality across high-speed printing industries is a significant challenge. The growth in speed and volume of printing makes traditional print quality control methods, like manual inspection, become impractical. This is where 100% print inspection systems come in. These systems provide a way to ensure all printed output meets quality standards and is quality-checked in real time without obstructing the flow of work.

Table of Contents

What is 100% Print Inspection

100% print inspection refers to automated quality control streamlining the inspection of each printed work in a given time period, confirming its standard and finding imperfections. In contrast to traditional methods of quality control where a small sampling is all that is checked, with these print inspection systems, guarantee that every single work is scrutinized and that all defective work is flagged to prevent any from reaching the final output.

Key Components

This chart provides an overview of the core components that enable 100% print inspection to operate efficiently and ensure high-quality output in high-speed printing industries.

| Component | Description |

| Cameras | High-resolution cameras capture detailed images of each printed item as it moves through the line. |

| Image Processing Software | Software that analyzes the images captured by cameras, comparing them to reference standards to identify defects. |

| Sensors | Optical, infrared, or laser sensors that detect surface imperfections, such as ink smudges, scratches, or misalignments. |

| Artificial Intelligence (AI) | AI algorithms that use machine learning to detect complex defects and adapt to new printing processes. |

| Lighting Systems | Specialized lighting setups (e.g., backlighting or diffused lighting) to enhance the visibility of print defects. |

| Defect Detection Algorithms | Pre-programmed or machine-learned algorithms designed to identify specific print defects like color variations, misprints, or pattern errors. |

| Real-time Feedback Mechanism | A system that provides immediate feedback to operators if a defect is detected, enabling quick intervention to avoid waste. |

| Barcode and QR Code Readers | Sensors dedicated to ensuring the accuracy and readability of printed barcodes or QR codes, commonly used in packaging. |

| Color Inspection Systems | Advanced sensors and software that ensure color accuracy, comparing printed output against a color reference model. |

| Print Positioning Detection | Systems that ensure the print is positioned correctly on the material, useful in label or packaging printing. |

Why Need 100% Print Inspection in High-Speed Printing

1. Ensuring Consistent Quality Across Every Print

Sectors like packaging, labeling, and security printing stake a reputation on the quality of printing, which in turn influences the performance of the final product. Minor imperfections, such as a misplaced logo or an ink smudge could be grounds for a complete batch rejection. Traditional method of manual inspection where only a small samples of prints undergo quality control checks can be flawed. In contrast to manual method, 100% print inspection systems provide a consistency that is unattainable through manual processes. They guarantee that each and every print is quality checked and no defective prints reach the customer. Quality control systems, which allow the inspection every single print runs, ensure consistency and quality to a degree that no other method can offer.

2. Minimizing Waste and Operational Cost

An important advantage of 100% print inspection is a decrease in waste. In high-speed printing, if a defect is not caught at an early stage, defective prints may run in large quantities before the issue is noticed. This wastes raw material, and needlessly increases expenses related to reprint and error correction. Automated systems inspecting everything in real time while defecting are avoided early in the process. Waste-materials and re-doing work on a large scale re-issue are substantial over time.

3. Increasing Production Efficiency

High-speed printing presses are constructed to run rapidly, creating thousands of prints each minute. The challenge of sustaining quality at such rates is to guarantee that each print is exhaustively verified, and that the process is not slowed down. Inspection becomes the weak link in the process cycle. Automated inspection systems for printing quality is a solution whereby the system is integrated to work at the same speed of the press. Quality inspection is performed inline to the print process. This ensures that the printing operation continues in an efficient, streamlined manner.

4. Maintaining Brand Integrity and Compliance Standards

When it comes to packaging food, print packaging for pharmaceuticals, or security printing, the consumer experience and print quality are closely intertwined with safety. Each and every printed item must be without defects. Compliance problems or a damaged reputation can stem from even the smallest quality oversight. Brands can have the confidence of meeting regulatory and brand standards with the implementation of 100% print inspections. The brand can rest assured that the product is exactly as intended for the customer. This is vital in legal compliance, advertising, or branding printed materials.

5. Real-Time Feedback for Quick Correction

One of the best aspects of implementing a 100% print inspection system is the capacity to provide real-time feedback to the people who operate the systems. Upon the detection of a defect, the system will send a report, meaning the operator can either adjust or repair the defect at the moment it occurs. This aids in the detection and resolution of issues that arise, preventing the problems from escalating and negatively impacting the entire production batch. With the immediate feedback, the entire production process becomes more flexible, and systems can make rapid changes, thus reducing production downtime.

6. Reducing the Risk of Human Error

In the world of high-speed production printing, most operators are seasoned, yet even the best miss some printing defects with the speed and pressure of production deadlines. Human oversight becomes unavoidable, especially in quality control over large volumes of prints. Automated 100% print inspection technologies offer reliable alternatives. With machine vision systems and AI algorithms analyzing every print, the likelihood of undetected defects diminishes dramatically. This technology delivers an unwavering dependability that human inspectors are incapable of providing, and offers constant output without the variable inconsistencies that human inspectors are predisposed to artificial judgment.

7. Adapting to Increasing Consumer Demands for Perfection

Consumers’ expectations of perfection in every product are a defining characteristic of the current purchasing climate. Customers have no tolerance for printing defects, whether for packaging, promotional materials, or even product labels. Under such pressure, brands must ensure that 100% print inspection delivers flawless prints to meet these expectations. With rising consumer demands, print operations must implement automated inspection technologies in order to remain competitive in a marketplace where high quality standards are the norm.

Common Defects Detected by 100% Print Inspection Systems

This chart highlights the most common defects that a 100% print inspection system is designed to detect, helping maintain high-quality standards across large-volume printing processes.

| Defect Type | Description |

| Misprints | Prints that are incorrectly aligned, misregistered, or have missing elements, such as text or graphics. |

| Ink Smears or Smudges | Unwanted ink blots or smears caused by improper drying or contact with other surfaces. |

| Color Variations | Subtle shifts in color, such as gradients or mismatched hues, which can lead to inconsistencies in branding. |

| Missing or Incorrect Text | Text that is incomplete, incorrectly printed, or misplaced, affecting readability or product labeling. |

| Barcode or QR Code Errors | Scanning issues where barcodes or QR codes are misprinted, unreadable, or incorrectly positioned. |

| Surface Imperfections | Scratches, dents, or wrinkles on the printed surface that affect the print’s appearance or texture. |

| Dot Gain or Loss | Inaccurate dot patterns where ink spreads too much (dot gain) or too little (dot loss), affecting sharpness. |

| Misaligned Prints | Displacement of the print image in relation to the material, resulting in crooked or off-center designs. |

| Broken or Distorted Graphics | Graphics or images that are incomplete or distorted due to printer malfunction or material issues. |

| Ink Bleeding | Ink spreading beyond the intended boundaries, leading to blurred or messy edges. |

| Halftone Defects | Issues with halftone printing, such as visible dot patterns or unclean transitions between tones. |

| Registration Errors | Misalignment between different color layers or components, leading to blurry or double-imaged prints. |

| Textural Defects | Variations in texture, such as inconsistent gloss, matte finish, or unintended patterns. |

High-speed Printing Applications of 100% Print Inspection

1. Packaging industry

Equally important as the quality of the print is the perception of the print packaging. The print packaging quality is the first indicator a consumer uses to assess a product and to form a perception of a brand. Packaging includes food packaging, pharmaceuticals, and bottle labeling, and must adhere to quality standards that encompass the composition as well as the regulatory aesthetic requirements.

100% print inspection systems for packaging quality are best fitted to identify defects that harm the marketability of products and packaging safety. Misprints, the positional errors of labels and the reference labels that diverge in color are defects that create confusion in the packaging and that provoke regulatory action. Inspecting all prints, all packaging is guaranteed to be visually perfect.

2. Labeling and Barcode Printing

Retail, logistics, and manufacturing industries all place great importance on labels. Labels must contain accurate information, including product details, barcodes, and QR codes, must be legible and well aligned. Barcodes that are used to scan products at the point of sale and during shipping are crucial, and any printing errors can lead to inventory discrepancies and considerable delays.

Every label generated by a printing company needs to be checked under a 100% print inspection system for label, ensuring proper readability and alignment. Such systems check to see if barcodes and QR codes have been printed correctly for scans. They also check if any text issues like spelling errors and wrong product information are printed, thereby, preventing operational disruptions in the supply chain for costly and inefficient rectifications.

3. Security Printing

Counterfeiting and fraud can be committed on printed documents like banknotes, passports, tickets, and other printed government documents. This means the quality of security printing and the absence of defects are critical. Even one small defect can be introduction of a fake or counterfeit printed documents which breaches security.

High-speed security printing demands the effective deployment of 100% printing inspection systems to find defects like alignment, shifts in color, broken security features, and serial numbers that have been misprinted. Systems that are designed for 100% print inspection in high speed security printing ensure that no printed documents can be counterfeited or forged and are compliant to security standards. They also ensure that the documents maintain their integrity and withstand sensitive use.

- Textile and Fabric Printing

Predominantly, the fabric printing industry focuses on vibrant prints for clothing and home textiles, precision, and the maintenance of consistency in color and sharpness. While designs in fabric printing are mostly intricate and complex, 100% print inspection is a necessity to ensure the finished product is the designated print requirement.

Inspection systems are able to identify flaws, including color mismatches, alignments, and overlaps as well as pattern distortions that have a bearing on print quality. They also evaluate consistency in the distribution of ink, where the color balance is needed across large volume. With the rise in the speed of textile printing due to advancements in digital and screen printing, 100% full-surface print inspection systems continue to be integral in the maintenance of quality.

4. Commercial Printing (Magazines, Books, and Brochures)

Uniformity in the textual content, visual aspects of the images, and color reproduction are critically important in commercial printing for magazines, books, and brochures. For high volume printing presses, the speed that produces thousands of pages in a minute, is usually the cause of defects, which include, misprints, inconsistencies in color, and blurred images. Automated 100% printing inspection systems avoid potential defects that can undermine the readability and the aesthetics of the final product. By the time the print pages are completed, every page has been screened for faults including blurred texts, inaccurate colors, and poorly aligned images, thus, removing the potential for defects that might affect the aesthetics of the final product.

5. Offset and Flexographic Printing

Cost efficiency in both offset and flexographic printing relies primarily on the speed of the machine. However, the speed of the machine coupled with the high-volume print runs creates the potential for print defects due to the misalignment of ink density, poor registration, or poorly aligned stacked prints.

Real-time detection of misalignment and registration faults dramatically reduces defects and waste in large print runs. 100% print inspection systems maintain quality control from the first print to the last. They reduce the operational costs associated with print reworks and unnecessary wastage of substrates. As a bonus, the feedback loop of the system allows for seamless operational changes to avoid the machine idle time, thus, improving throughput.

6. Printed Electronics and Circuits

Printed electronics employs novel techniques to create circuits and other components. Conductive inks and materials are printed on various substrates. During high-speed printed circuit board (PCB) manufacturing or the production of flexible electronics, it is essential to guarantee precision and uniformity of prints to attain the desired functionality.

To ensure that all the electronic constituents are credible and functional, 100% printing inspection ascertain that misprints, broken trace lines, absent conductive pathways, and other discrepancies in patterns are identified and corrected. Because printed circuits are crucial for the dependability and effectiveness of electronic devices, the growing demand for printed circuits in the automotive, IoT, and wearable technologies will continue to increase the importance of inspection systems.

7. Food and Beverage Packaging

The food and beverage industry has highly engineered informative and promotional printed materials on their packaging. These include sophisticated graphics, and in-text elements like logos, nutrition education labels, and ingredient lists which can present complex legal requirements. These prints must be defect free to ensure consumers trust the product, and compliance regulations are met.

Every piece of food and beverage packaging undergoes a 100% print inspection to ensure accuracy and completeness of every text and label. Systems can recognize a wide variety of defects such as improperly aligned images, incorrect labeling, and missing expiration dates. This assists with compliance for food labeling regulations. It removes the packaging for food and beverage products that are likely to cause expensive recall, and consequently, removes packaging that is flawed before it goes to the consumer.

8. Pharmaceutical Packaging

Pharmaceutical products come with a different set of packaging and print requirements that are also highly regulated. Besides the already mentioned product information, packaging must indicate the dosage, batch number, and expiration dates. Print defects can be legally and administratively costly as well as posing serious health risks.

100% print inspection systems ensure high accuracy in pharmaceutical packaging, detect ing misprints and determine if the labels are aligned properly and if the colors match. This system must also ensure that properly labeled packages are sent to the market and that errors are minimized.

Challenges in Implementing 100% Print Inspection Systems

This chart highlights the various hurdles companies may face when implementing 100% print inspection systems, from financial investment to technical complexity. Addressing these challenges requires careful planning, resource allocation, and continuous updates to keep pace with advancements in printing inspection technology.

| Challenge | Description |

| High Initial Investment | The upfront costs of advanced cameras, sensors, software, and integration with existing equipment can be substantial, posing a financial barrier for smaller businesses. |

| Integration with Legacy Equipment | Older printing presses may require significant modifications or upgrades to be compatible with modern inspection technologies, causing potential downtime and added costs. |

| Complex Defect Detection | Detecting subtle defects such as color variations, intricate design flaws, or microscopic errors remains a challenge, requiring highly sophisticated systems and advanced algorithms. |

| False Positives and False Negatives | Automated systems may incorrectly identify defects (false positives) or miss real defects (false negatives), leading to inefficiencies, production stoppages, or undetected errors. |

| Environmental Factors | Lighting conditions, substrate variations, and print speed can interfere with image capture and defect detection, requiring specialized systems and settings to handle diverse environments. |

| Training and Expertise Requirements | Operators and technicians need extensive training to understand, operate, and maintain the system, especially with complex AI-driven software and high-tech imaging equipment. |

| Maintenance and Upgrades | Regular maintenance, calibration, and periodic software or hardware upgrades are necessary to ensure continued accuracy, which can result in added operational costs. |

| Cost of System Downtime | Installation or maintenance of inspection systems may lead to production downtime, disrupting workflows and impacting delivery schedules, particularly in high-volume environments. |

| Scalability Issues | As production volumes increase, the inspection system must scale efficiently, which can involve further investment in additional hardware or upgrades to handle larger workloads. |

| Adapting to Evolving Industry Standards | As print technologies and materials evolve, inspection systems need to adapt to new print methods, requiring constant updates to software and algorithms to maintain compatibility. |

Future Trends in 100% Print Inspection

As new technologies emerge and consumer expectations rise, the future of 100% print inspection is poised for significant advancements.

1. Increased Integration with Artificial Intelligence (AI) and Machine Learning

The future of 100% print inspections is shaped by the advance of the constant integration of Artificial Intelligent and Machine Learning technologies. Although the use of these technologies is present today, the future of print inspection will be driven primarily by the advance of Artificial Intelligent and Machine Learning algorithms. Such systems will not only go on to detecting and locating defects, and predicting, potential, future, problems prior to their occurrence. This will certainly make inspection more preemptive than reactive.

Future AI-powered systems will be able to analyze complex kinds of defects, learn from the historical information and increasingly refine their own detection systems. This implies that the systems will more efficiently be able to recognize and capture new more sophisticated defects, as well as adapt to the dynamic changes of print technologies and/or print materials. Self-learning algorithms will increase the inspection system’s autonomy requiring less manual calibrations, thus closing the feedback loop and improving efficiency.

2. Enhanced Vision Systems and High-Resolution Imaging

With advancements in printing technology, there is also an increase in the intricacy of printed designs, thus magnifying the importance of the vision systems in 100% print inspection. Looking ahead, inspection systems will incorporate higher resolution cameras and sophisticated print imaging systems capable of detecting the most minor of imperfections. These systems will function at a higher resolution and will be able to detect changes in color, erroneous text, and more detailed design flaws that current systems overlook.

In addition, the use of multi-spectral imaging and the new generation of hyperspectral cameras will allow print inspection systems to take photographs in different light spectra and layers, capturing more details pertaining to problems that are obscured to the naked eye and conventional cameras. For defects like variability of ink, flaws of the substrate, and other issues on the surface, the improved imaging systems will provide more detailed information on the overall print quality.

3. Faster and More Accurate Real-Time Feedback

As the demand for high-speed printing increases, the demand for print inspection systems also increases. These systems are projected to offer more responsive, more accurate feedback to ensure defects are found and repaired on the fly, without halting the inspection process. These systems will have the capability to process information and detect problems within seconds, and provide feedback to operators and inspectors, enabling real-time modifications to problematic prints. The goal is to stop defective prints from passing through the inspection system and printing the items.

Increased feedback speed will also trigger the systems to provide advanced feedback on defect identification, negating the need for operators and inspectors to make guesses as to the defect type on the print, and thereby, the best method to resolve the problem. This will streamline the problem-solving process, minimize delays, and optimize production.

4. Automation of Defect Correction

While automation of defect detection within print inspection systems is a trend, the next and most advanced phase of such systems will focus on the automation of defect correction. Advanced systems will detect print defects and, within seconds, adjust printing machine parameters such as alignment, color, and ink application to fix the problems.

Closed-loop feedback systems will enable automated print inspection systems to instantly modify parameters on the presses or print material handling systems to correct defects mid-production. This innovation will minimize the need for manual corrections and improve the production process speed and efficiency considerably.

5. Improved Sustainability and Waste Reduction

As a priority in manufacturing, sustainability will be supported by 100% print inspection systems on the production line. Early recognition of print defects enables the systems to reduce the quantity of defective prints that must be scrapped or reprinted, thus mitigating the loss of valuable resources such as ink and substrate. The material efficiency and sustainability of the process will therefore be enhanced.

Additionally, 100% print inspection systems will improve the process efficiency to the extent that energy consumption will also be reduced, thus contributing to the sustainability of the model. The packaging industry in particular will benefit from better waste management as inspection systems will help alleviate material waste and the adverse environmental effects associated with them.

6. Personalized Print Inspection for Customization

The rise in demand for bespoke products has led to a greater need for high-volume customized prints within the printing industry. 100% print inspection systems will develop with the goal of allowing for personalized quality control for every single print.

As brands are increasingly adopting personalized packaging and individualized labels, print inspection systems will also need to guarantee that every tailored print meets the precise requirements for color, positioning, and overall quality. This will demand more advanced systems with the capacity to adjust to and balance an even greater range of printing parameters, including variable text, custom images, personalized color schemes, and all other requirements, without compromising on the processing speed and precision of the print.

Final Thoughts

The benefits and advanced technology, including machine vision, various sensors, and the integration of AI, that drive 100% printing inspection systems to ensure quality control in high-speed printing industries is undeniable. While the challenges in implementation are real, the potential benefits in terms of waste, inefficiency, and costs make 100% print inspection an investment that more printing companies are willing to make in order to stay competitive in an increasingly demanding market.