Automatic Tension Controller – Used For High Precision Control For Web Tension

The tension controller is a high-precision instrument with digital, automatic control for web tension. It can be widely used in tension control of the printing, packaging, paper, textile and dyeing industries. Web tension controller adopts the CPU of 16-bit or 32-bit, with high speed, high precision, high reliability.

Why Choose The Automatic Tension Controller

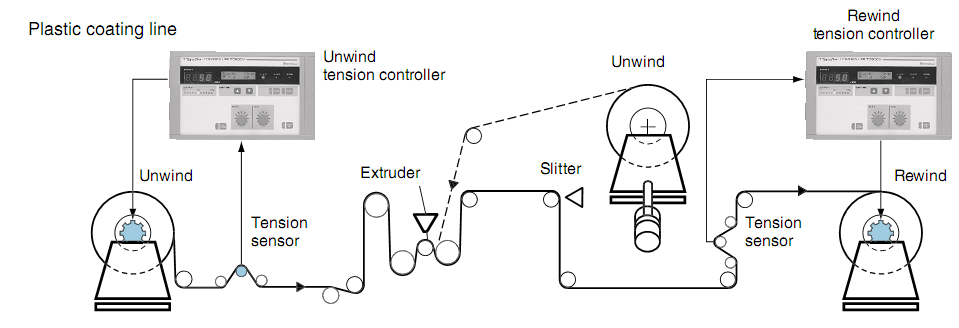

A typical tension control system is mainly composed of a tension controller, a tension reader, a tension sensor, a magnetic powder brake, and a clutch. Depending on the loop, it can be divided into types of open loop, closed loop or free ring. According to the monitoring method of different coils, it can be divided into types of ultrasonic, floating roller, tracking arm. The stability of tension control has directly affected the quality of the slitting products. If the tension is insufficient, it will generate drift in the raw materials moving and the finished paper wrinkle will appear after the rewinding. If the tension is large, the raw material is easily broken, so that the finished products will appear more broken ends after the rewinding.

The Performance Of The Automatic Tension Controller

The tension controller refers to the durable control of the tension performance when the feedstock is stored on the device. This control is required to be valid for any operating speed of the machine, including the deceleration, acceleration, and uniform speed of the machine. Even in emergency parking conditions, it should be guaranteed that the parties are not damaged.

The automatic tension controller is a control instrument that can directly set the tension value of the controlled machine, then directly output the signal of the tension sensor as a tension feedback value, after the proposed bias, outputting to the PID controller for disposal. Then input to the core executive agency to control and finally arrives the purpose of a small bias.

Function Of The Automatic Tension Controller For Unwinding And Rewinding

In the control industry, in some strip-shaped and line-shaped products, tension control is required to achieve production requirements. The general tension controller also has a volume extent function, which is generally applied to the down coiler equipment, with unwinding and winding types. The tension controller also has a taper adjustment function that can be sent directly to the winding taper on some processes inside the controller.

Fully automatic tension control is the actual tension value of the material, measured by the tension sensor directly, and then converts the tension value into a tension signal feedback to the tension controller. Through the comparison of this signal and the pre-set tension value, calculates the control signal. The automatic control execution unit makes the tension value is equal to the pre-set tension value, to achieve a stable purpose for tension control. A fully automatic tension controller is an advanced tension control method.

The fully automatic tension controller measures the actual tension of the coil materials and automatically adjusts the tension value of the coil according to pre-set tension value through the PID algorithm. It has extremely high accuracy tension control, suitable for applications where have high requirements for the accuracy of the tension controller.

How To Solve The Malfunction Of The Automatic Tension Controller

1. The automatic tension controller adopts the AC 185-264V power supply. After the current is switched on, if the tension controller does not work, check if the power supply is connected correctly or whether the fuse is abnormal.

2.If the display signal is incorrect, can re-set the correct signal range. Check the route and the tension sensor whether there is a signal fault or replace the tension sensor.

3.If the tension controller has no signal output, usually there is a connection problem, so check whether the signal output connection is correct, then turn off the voltage for ten seconds and then switch on.

4.If the tension controller signal output is unstable, check whether the roller, bearing and magnetic powder clutch, brake, or driver have an abnormality. Replace the tension sensor or re-calibrate the signal range.

Summary

The automatic tension controller provides high-precision tension control in the unwinding and rewinding process for different coil materials. It adopts PID algorithm control. It has the advantages of simple operation, high reliability & stability, strong anti-interference and easy installation.