Edge and Center Web Guiding with Multi-sensor Fusion

Web guide systems have become extremely important for the manufacturing processes involving raw materials such as paper, film, textile, and metal foils. Proper web guiding helps in aligning materials, reducing waste, and increasing production. In the past, web guiding techniques have used single-point sensors, which focus on either the edge or the center of the web. The shift towards multi-sensor fusion technology brings more accuracy, reliability, and flexibility in the industry.

Table of Contents

Understanding Edge and Center Web Guiding

Edge Web Guiding

Edge web guiding system is used to determine the lateral position with the aid of optical, ultrasonic, and mechanical sensors. Edge guiding has earned a lot of traction for its effortless reliability, especially if the material we are using has straight edges. As a result, it is handy for high speed web processing. Even though edge guiding is reliable, if we are working with materials that have frayed or irregular edges it, is certainly going to give a wide range of processing interruptions.

Center Web Guiding

Center web guiding system identifies the web’s midline and follows the midline instead of the edges. This is useful when the edges of the web are poorly marked, damaged, or inconsistent in width. Certain sensors are used to line track in real-time, and the guiding system then alters the web’s position. Center guiding is useful in applications where web edge detection is unreliable or if the web material is thin and likely to deform at the edges. Center web guiding, like other web guiding systems, depends on a line of symmetry that is visibly marked. It also is affected by angular displacement of the markers, changes in the web’s surface, or aligned markings within the web.

Comparison of Edge and Center Web Guiding

This chart clearly highlights the differences, strengths, and typical industrial applications of edge and center web guiding methods, providing a concise overview for comparison and decision-making.

| Aspects | Edge Web Guiding | Center Web Guiding |

| Reference Point | Web edges | Web centerline or reference mark |

| Web Guide Sensor Types | Optical, ultrasonic, laser | Optical, mark-detection, vision systems |

| Strengths | Simple, fast response, effective on well-defined edges | Effective for irregular or damaged edges, tracks specific center features |

| Limitations | Struggles with frayed or inconsistent edges | Requires consistent center reference; affected by misaligned marks |

| Material Suitability | Webs with clear, consistent edges | Webs with irregular edges or variable width |

| Adaptability | Limited under irregular edge conditions | Higher adaptability to challenging materials |

| Integration Potential | Can be combined with center guiding for better accuracy | Can be combined with edge guiding in multi-sensor fusion |

How Multi-sensor Fusion Works for Edge and Center Web Guiding

The advent of multi-sensor fusion has revolutionized web guiding by combining data from multiple sources, providing enhanced accuracy, reliability, and adaptability.

Understanding Multi-sensor Fusion

Combining different types of data from several sensors and creating a singular more accurate and dependable measurement of the web position is called multi-sensor fusion. In web guiding, it merges centerline tracking and edge detection. W hen the sensors work together, the web is far more likely to be positioned accurately than when each sensor works independently and especially when conditions are poor due to irregular edges, varying web tension, centerline damage, or more.

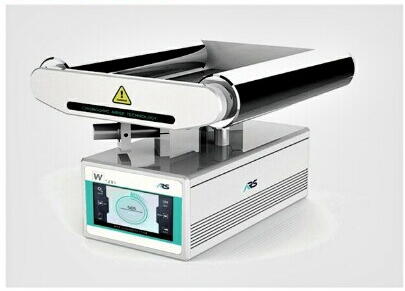

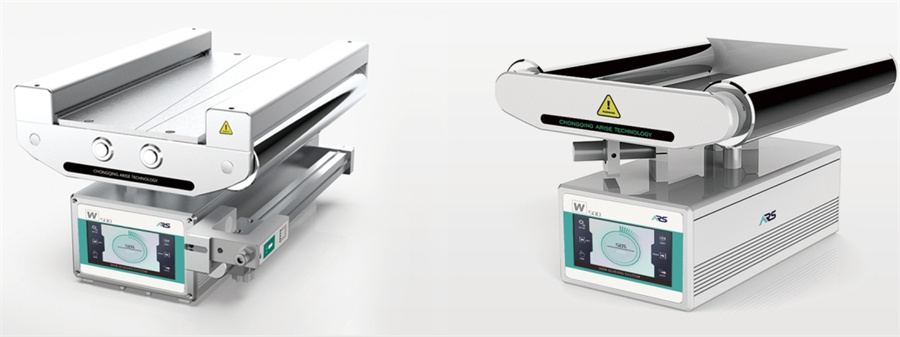

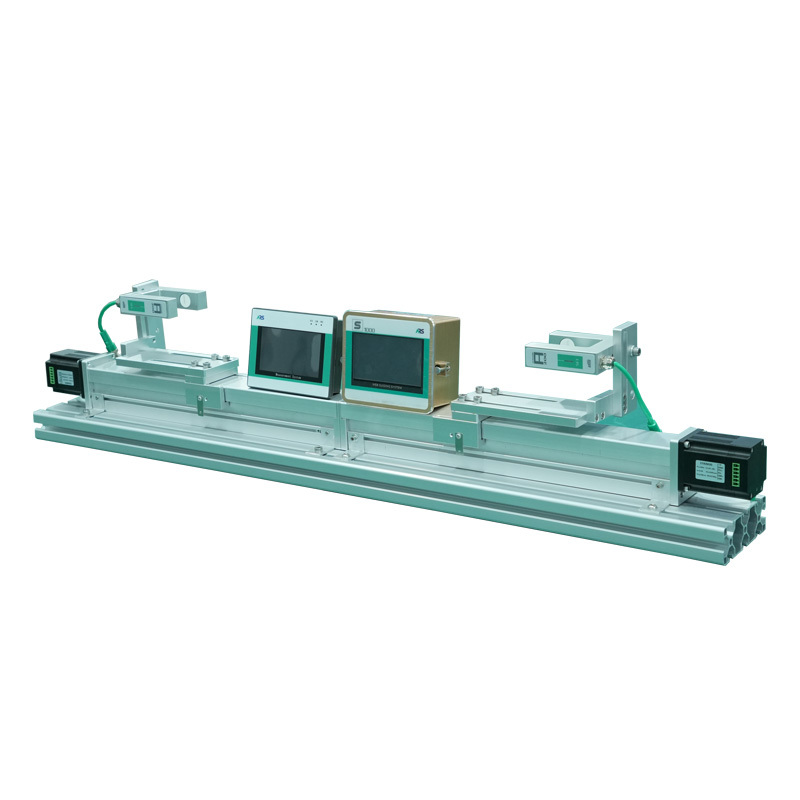

Edge and Center Sensor Integration

Edge sensors, Used by web touchless guides, laser, ultrasonic, and even optics, as well as others, determines when the web is touching the edges. Centerline sensors observe reference marks or features that are located on the web’s center. Combining both tracks positioned by edge sensors and the centerline accomplishes better tracking, and more precise control. This is accomplished by Muti-sensor Fusion improving alignment by closing the gaps of the less precise sensors or more dominant parameters of edge sensors and centerline. The Control is from the most reliable edge measured by multi weighted and weighted center alignment, improving the precise control even on the most random of materials.

Data Processing and Decision-Making

The success of multi-sensor fusion depends on sophisticated algorithms asap to interpret and operate on the data. Sensor signatures are filtered and excess signals are screened for plausibility. The control system computes the optimal control action for the web alignment, which is relayed to the actuators or rollers. These disturbance responses are real-time and automatic and allow for stable production even at the fastest high-speed production.

Advantages of Multi-sensor Web Guiding

1. Enhanced Accuracy

Greater precision is perhaps the most important benefit of multi-sensor web guiding. With the edge sensors and centerline sensors systems, the web is positioned laterally even under difficult conditions. The sensor data is cross-referenced for sub millimeter accuracy to make certain high speed production alignment is maintained. Consistent alignment is critical for constant product quality to decrease defects and reworks.

2. Increased Reliability

Compared to a configuration dependent on a single sensor, a multi sensor setup provides improved reliability. The presence of multiple sensors minimizes the chances of errors that may occur from sensor failure, alignment, or obstruction with dust, vibration, light, vibration, and other external environmental conditions. If one sensor malfunctions or provides inconsistent data, as long as other sensors provide consistent data, the system will achieve proper web alignment. The system can operate with stable and continuous alignment under the toughest conditions.

3. Greater Adaptability

This trait is an advantage of the system since it can operate under varying materials and conditions. It is a challenge for single sensor systems to correctly align single layer webs with jagged edges, irregular widths, soft and fragile surfaces, or multi-layered webs. The guiding system can automatically or manually designate the most dependable sensor and provide alignment, or form a merged position using data from all the sensors. This feature permits multi-sensor web guiding systems to align webs for several industries such as paper and packaging, textile, electronic, and even thin metal foils.

4. Reduced Material Waste

By maintaining precise web alignment, multi-sensor systems help minimize off-spec production and material waste. Misaligned webs can result in defective products, unnecessary trimming, or production stoppages. Multi-sensor guiding reduces these occurrences, contributing to cost savings and improved sustainability. Over time, the ability to consistently produce accurate materials enhances operational efficiency and profitability.

5. Advanced Process Insights

Multi-sensor web guiding also has process monitoring and improvement capabilities. Sensors record information about the web’s tension and edge quality and the centerline’s Stability. This enables predictive maintenance and early issues detection. These insights allow the manufacturers to refine the control strategies, mitigate unplanned downtimes, and increase the overall production efficiency.

Applications Across Industries of Edge and Center Web Guiding with Multi-sensor Fusion

This chart highlights how multi-sensor fusion enhances web guiding performance in diverse industrial applications, ensuring precise alignment, reducing waste, and improving overall production quality.

| Industry | Application | Benefits of Multi-Sensor Fusion |

| Paper & Packaging | Printing, cutting, coating, and laminating | Maintains precise alignment for high-quality printing, reduces material waste, and ensures consistent product dimensions |

| Textiles & Nonwovens | Fabric alignment, coating, embossing | Handles irregular edges, maintains web tension, improves process efficiency and product quality |

| Electronics | Flexible circuits, printed electronics, and laminates | Ensures accurate positioning of delicate webs, prevents misalignment of components, and reduces defects |

| Metal Foil & Laminates | Coating, embossing, slitting | Achieves sub-millimeter alignment, minimizes material waste, and enables high-speed production with stable quality |

| Plastic & Film | Packaging films, labels, protective films | Enhances tracking accuracy, compensates for web tension variations, and ensures uniform coating or printing |

| Composite Materials | Layered composites, insulation materials | Maintains precise layer alignment, reduces errors in lamination, improves product consistency and performance |

Future Developments in Edge and Center Web Guiding with Multi-Sensor Fusion

1. Integration of Artificial Intelligence and Machine Learning

One of the most significant future developments is the integration of artificial intelligence (AI) and machine learning (ML) into web guiding systems. AI algorithms can analyze data gathered from several sensors in real time and anticipate possible deviations even before they happen. Machine learning systems can improve guiding precision by studying historical production data, variations in web tension, and environmental changes. With this level of prediction, one can use adaptive control systems for alignment control even in the most unpredictable situations.

2. Advanced Sensor Technologies

New web guiding sensor technologies, along with optical, ultrasonic, and lasers, will help in the more accurate detection of web edges and centerlines. It is anticipated that the new sensor technologies will also reveal even more precision, speed, and stability against environmental disruptions such as dust, vibrations, and light. These new sensors, along with multi sensor systems and the sensor fusion architecture, will boost manufacturers’ confidence in handling more complex and delicate materials such as fine webs, irregular edges, and varying thickness.

3. Digital Twin and Simulation Integration

Using digital twinning will increasingly become important alongside web guiding systems. With this technology, manufacturers will create virtual models of processes and simultaneously simulate rollers, controllers, and the rest of the systems before the real production process. This will optimize web tension, alignment, and corrective measures, therefore, reducing trial and error measures, material waste, and overall production efficiency. Digital twins allow real time monitoring and predictive system maintenance, thus augments their digital reliability.

4. Smart Actuation and Adaptive Control

An advanced approach to web guiding systems will integrate smart actuators that react to sensor detections instantly. With the fusion of multi-sensors data and AI, controlled logic will be able to make autonomous changes to roller positioning, tension, and speed. Such machines will always keep the web aligned and operational even at high production rates while processing complex materials that the system autonomously detects and reacts to.

5. Enhanced Data Analytics and Connectivity

As part of Industry 4.0 and the Industrial Internet of Things (IIoT), Data driven analytics of web guiding systems are integrated with correlated production networks. Web guiding systems gain valuable analyzable data from sensors regarding web tension processes, web guiding actuators, and overall process stability. Equipment maintenance and wear detection as well as production line maintenance and alignment are optimized using Automated Guided Vehicles (AGVs). These systems help central engineering control of several guiding systems across extensive production facilities.

6. Sustainability and Material Efficiency

Improved sustainability and material efficiency is linked with using energy conserving multi-sensor web guiding systems which minimizes material, energy, and environmental wastes. These systems results in a lower unit production cost and increased eco-friendly manufacturing systems optimization.

Summary

Edge and center web guiding with multi-sensor fusion means increased precision web handling. Now, manufacturers can attain high accuracy, reliability, and flexibility with improved product quality and reduced waste because the best features of multiple detection methods are seamlessly integrated. These systems will, of course, become even more sophisticated with advancements in technology and will offer instant observations and responsive control, thus, changing the standards of web-based manufacturing systems.