How to Maintain Consistency in Tension Control across Multi-layer Webs

Table of Contents

In the industrial handling of multi-layer webs, ensuring consistent tension control is essential to maintaining product quality and operational efficiency. Any deviation in tension can cause defects such as wrinkling, misalignment, or tearing, impacting both production costs and final output. This article explores the challenges, strategies and best practices to ensure consistency in tension control across multi-layer webs.

Challenges in Maintaining Consistent Tension Control across Multi-layer Webs

This chart highlights the diverse factors that need to be managed to achieve consistent tension control in multi-layer web processes.

| Category | Challenge | Impact |

| Material Properties | Variations in material thickness, elasticity, or surface friction | Causes uneven tension, slippage, or stretching across layers, leading to defects or misalignment. |

| Environmental Factors | Temperature and humidity changes affecting material behavior | Alters material dimensions or flexibility, causing inconsistent tension levels. |

| High-Speed Operations | Rapid processing amplifies minor inconsistencies | Leads to instability, web breaks, or wrinkles during production. |

| Layer Interaction | Different layers reacting differently to tension | Results in slippage, curling, or separation between layers. |

| Machine Dynamics | Mechanical limitations such as roller misalignment or inadequate braking systems | Creates tension imbalances or non-uniform distribution across the web width. |

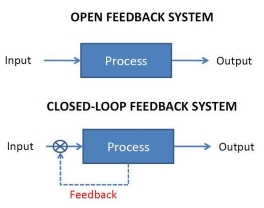

| Control Systems | Inadequate or outdated open-loop control systems | Lack of real-time adjustments can fail to correct tension fluctuations promptly. |

| Measurement Accuracy | Insufficient or poorly calibrated tension sensors | Results in incorrect tension readings, leading to over-correction or under-correction of tension. |

| Edge Tension Variance | Uneven tension distribution across the web width | Causes edge curling, wrinkles, or slack areas in the web. |

| Operator Error | Incorrect setup or adjustments during machine operation | Leads to inconsistent tension settings or improper calibration of control systems. |

| Maintenance Issues | Wear and tear on rollers, guides, or actuators | Reduces system efficiency and creates additional variability in tension control. |

| Multi-layer Complexity | Synchronizing tension for webs with diverse properties | Increases the likelihood of tension imbalances between layers, especially during acceleration, deceleration, or material transitions. |

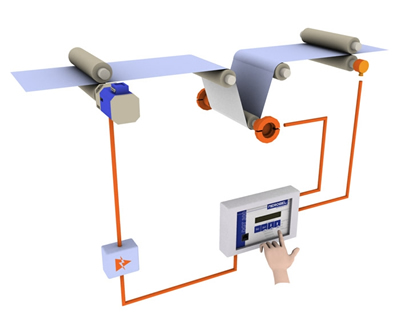

Key Components of Web Tension Control Systems

This combination of components works together in web tension control systems to ensure consistent tension during multi-layer processing, maintaining product quality and efficiency.

| Component | Function | Description |

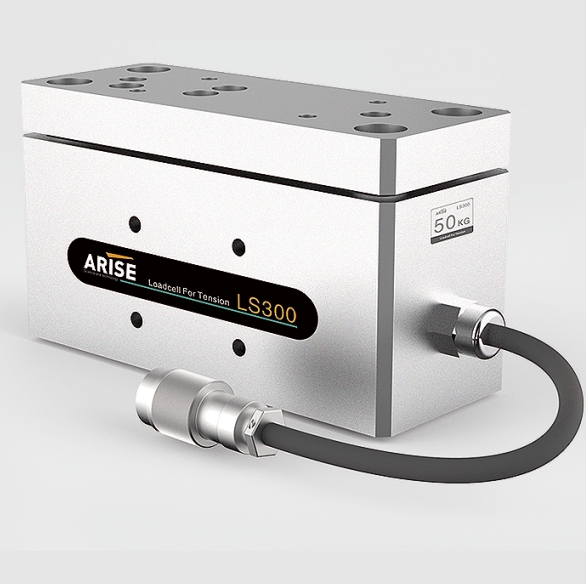

| Tension Sensors | Measure the web tension at specific points | Load cells, torque sensors, or capacitance-based sensors detect the tension in the web. |

| Web Tension Controller | Regulates the tension based on sensor feedback | A central unit processes data from sensors and adjusts controls accordingly. |

| Motors/Drives | Control the movement of rollers, spindles, or conveyors that move the web | Motors drive the unwind, rewind, or intermediate rollers, adjusting speed for tension control. |

| Brakes | Provide resistance to slow down or stop the web movement | Mechanical or pneumatic brakes apply adjustable resistance to regulate tension. |

| Clutches | Engage or disengage rollers, providing precise control of web motion | Clutches control the engagement of rollers to modulate tension adjustments. |

| Web Guide Systems | Ensure the web stays aligned and does not skew during processing | Guides, rollers, and edge sensors maintain web alignment, preventing tension imbalances. |

| Actuators | Make adjustments to mechanical components based on control signals | Pneumatic or electric actuators adjust the position of rollers or the engagement of brakes. |

| Feedback Loop | Provides continuous real-time data for maintaining tension consistency | A feedback mechanism ensures ongoing adjustments to web tension for stability. |

| Speed Controllers | Synchronize the speed of rollers or conveyors with the web tension | Adjustments to the speed ensure that the web’s velocity matches the desired tension levels. |

Strategies for Maintaining Consistent Tension Control across Multi-layer Webs

1. Implementing Independent Tension Zones

- Each layer in a multi-layer web often has unique physical properties, such as thickness, elasticity, and friction.

- Use independent tension zones to control each layer individually, enabling precise adjustments without impacting other layers.

- Separate control prevents issues like layer slippage or uneven tension distribution.

2. Adopting Closed-Loop Tension Control Systems

- Closed-loop tension control systems dynamically adjust tension based on real-time feedback from sensors.

- These systems continuously monitor tension levels and make automated corrections to maintain consistency.

- Compared to open-loop systems, closed-loop designs are more responsive to sudden changes or material inconsistencies.

3. Utilizing Advanced Sensor Technologies

- Incorporate load cells, ultrasonic sensors, and optical tension meters for accurate, real-time measurements.

- Use advanced tension sensors to detect tension fluctuations across the web’s width, ensuring uniform control.

- Smart sensors with IoT integration enable remote monitoring and predictive maintenance, further enhancing reliability.

4. Optimizing Material Handling and Preparation

- Begin with materials that have uniform thickness, elasticity, and surface finish.

- Use pre-treatment methods like corona treatment to improve adhesion and reduce slippage.

- Properly align web layers during loading to avoid initial tension mismatches.

5. Leveraging Tension Profiling and Pre-Set Parameters

- Develop tension profiles for different materials and applications.

- Store pre-set parameters in tension controllers to simplify setup for recurring jobs.

- Tension profiling ensures repeatable, consistent results for multi-layer processes.

6. Maintaining Equipment and Calibrating Regularly

- Perform routine maintenance on brakes, clutches, motors, and sensors.

- Calibrate tension measurement devices periodically to ensure accuracy.

- Check for wear and tear on rollers and web guides that can disrupt tension consistency.

7. Incorporating Adaptive Technologies

- Use AI-driven tension control systems that learn from historical data to optimize tension adjustments.

- Implement digital twin simulations to predict tension behavior under various operational conditions.

- Adapt the system to environmental factors like temperature and humidity changes that may affect web tension.

8. Balancing Tension Across Web Width

- For wider multi-layer webs, ensure tension is evenly distributed across the width to avoid edge curling or slack.

- Use spreader rollers or bowed rollers to counteract edge tension imbalances.

- Monitor lateral tension variances using cross-web tension sensors.

Industrial Applications of Consistent Tension Control across Multi-layer Webs

This chart highlights how consistent tension control is critical across various industries, ensuring product quality, operational efficiency, and customer satisfaction.

| Industry | Application | Role of Consistent Tension Control | Key Benefits |

| Printing | High-quality multi-layer printing on paper, film, or foil | Ensures accurate registration and uniform ink transfer across all layers | Reduced waste, improved print clarity, and precise alignment |

| Packaging | Laminated flexible packaging materials | Maintains adhesion strength and prevents wrinkles or misalignment during lamination | Enhanced product appearance and durability |

| Labeling | Pressure-sensitive and multi-layer labels | Prevents label material distortion and ensures precise die-cutting and alignment | Consistent label quality and reduced material rejection |

| Laminating | Multi-material composite laminates | Ensures proper bonding and layer alignment during high-speed lamination processes | Improved structural integrity and minimized delamination risks |

| Coating | Applying adhesive, protective, or functional coatings | Maintains even coating thickness and avoids layer separation or wrinkles | Uniform coating application and high-quality end products |

| Textile Manufacturing | Multi-layer fabrics or composites | Prevents layer shifting, stretching, or tension-related fabric defects | Consistent fabric texture and durability |

| Battery Production | Lithium-ion battery electrode and separator layering | Ensures precise tension to avoid misalignment or damage to delicate components | Increased battery performance and reliability |

| Pharmaceuticals | Blister packaging and multi-layer medical films | Prevents material breakage or misalignment during high-precision production | Ensures compliance with safety and quality standards |

| Food Industry | Multi-layer vacuum-sealed or barrier films | Maintains seal integrity and consistent film thickness during packaging | Increased shelf life and product protection |

Overall, through using advanced technologies, adopting best practices and tailoring solutions to industry-specific needs, manufacturers can maintain consistent tension control across multi-layer webs and keep competitive in their respective markets.