How to Select a Right Web Guide Machine

Web guide machines are essential in businesses requiring constant web handling and processing, such as printing, packaging, textiles, and paper manufacture. These devices enable accurate web alignment and control, resulting in higher product quality, less waste, and increased production efficiency. However, with so many different types and models on the market, choosing the right web guide machine for your unique needs can be difficult. In this article, we will discuss the topic on how to select a right web guide machine, providing the different types of web guide system and the essential factors to consider when choosing a web guide machine for your industry.

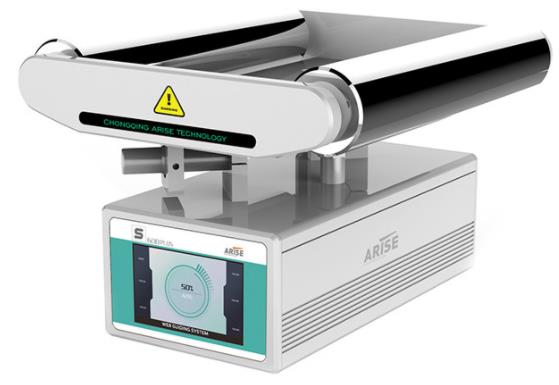

Types of Web Guide Machines

There are various types of web guide machines, each designed to meet certain uses and requirements.

Edge Web Guiding Systems

The most common type is web edge guiding system. These devices detect the edges of the material to monitor and manage the position of the web. Sensors on either side of the web constantly monitor the edge positions of the web, and the control system makes modifications to keep the web centered and aligned.

Center Web Guiding Systems

Center guiding systems, sometimes referred to as line guiding systems, regulate the web based on its centerline. The device detects the center location of the web with a single sensor and changes the guiding mechanism accordingly. Center directing systems are especially effective when the edges of the web material are irregular or inconsistent.

Sensor-Based Web Guide Machines

Sensor-based web guide machines utilize various sensor technologies to detect the web’s position and make adjustments. Some common types of web guide sensors include ultrasonic sensors, infrared sensors, line-scan cameras, and laser sensors. Each sensor technology has its advantages, and the choice depends on factors such as the web material, production environment, and level of precision required.

Hydraulic Web Guide Machines

Hydraulic web guide machines use hydraulic actuators to alter the location of the web in real time. These machines are ideal for heavy-duty applications and scenarios where a large amount of force is required to correctly guide the web.

Pneumatic Web Guide Machines

Pneumatic actuators control the position of the web in pneumatic web guide machines. They are well-known for their quick responsiveness and exact adjustments, making them ideal for high-speed manufacturing processes.

Electric Web Guide Machines

Electric actuators control the position of the web in electric web guide machines. They are frequently favored because to their low energy consumption and simplicity of interaction with other automated systems.

Factors to Consider When Choosing a Web Guide Machine for Your Industry

Choosing the right web guide machine for your industry is a crucial decision that can have an impact on production productivity, product quality, and overall operational effectiveness.

Types of Web Material

Consider the web material used by your industry, such as paper, film, foil, fabric, or non-woven material. Different web materials have different properties and requirements, and the web guide machine should be compatible with the material you’re working with.

Web Width and Speed

Determine the web guide machine’s maximum and minimum web widths as well as production speeds. Choosing a machine that can fit your entire range of web widths and speeds is critical for smooth operations.

Alignment Precision

Determine the precision necessary for your production process. Printing and converting industries, for example, may demand web guide machines with modern sensing technology and accurate control mechanisms.

Guiding System Type

Choose the appropriate type of guiding system for your needs. For continuous and constant webs, edge guiding systems are usually employed, but center guiding systems are favored for uneven or inconsistent edge materials.

Sensor Technology

Take a look at the sensor technologies used in the web guide machine. Ultrasonic, infrared, line-scan cameras, and laser sensors are examples of common sensor types. Each sensor type has advantages and disadvantages, so select the one that best fits your web material and guiding requirements.

Control Mechanism

Examine the many control mechanisms available for the online guide machine. Automatic control systems make real-time modifications based on sensor feedback, whereas manual control requires operator interaction. The option you select is determined by the level of automation and operator engagement intended for your process.

Integration with Existing Equipment

Ascertain that the web guide machine can interact easily with your existing manufacturing equipment and automation systems. Compatibility with other machinery is critical for effective operation and communication between systems.

Web Tension Control

Consider web guide machines with integrated tension control functions if web tension management is crucial for your process. Maintaining web stability and product quality requires proper web tension controller.

Maintenance and Support

Assess maintenance requirements of the web guide machines and the availability of technical help from the manufacturer or supplier. Regular maintenance and dependable support are required to ensure the machine’s longevity and peak performance.

Cost and Return on Investment (ROI)

While cost is an important consideration, consider the long-term ROI rather than just the initial expenditure. A high-quality web guide machine that increases production efficiency and product quality can yield large long-term profits.

Training and User-Friendliness

Consider the online guide machine’s usability and the availability of operator training. Proper training will help operators to efficiently utilize the machine and troubleshoot small faults.

Summary

The right web guide machine is an important decision that can affect the efficiency and productivity of your manufacturing process. A well-chosen web guide machine can result in higher product quality, less waste, and more efficient production processes, all of which contribute to your company’s success.