Printing Inspection Systems: Ensuring the Quality and Safety of Labels and Packaging

Quality and safety are critical in the field of product packaging and labeling. Obtaining this level of precision and dependability can be difficult. Printing inspection systems are critical to attaining these goals. These cutting-edge technologies use a mix of precision optics, image processing, and artificial intelligence to inspect labels and packaging with unrivaled precision. In this post, we will look at how printing inspection systems play an important part in label and packaging quality and safety.

Why Printing Inspection Systems are Necessary in Labels and Packaging

Before delving into the specifics of printing inspection systems, it’s crucial to understand why quality is so crucial in labels and packaging.

Consumer Trust

High-quality labels and packaging instill trust in consumers. When a product arrives in pristine packaging, consumers are more likely to believe it has been handled and produced with care.

Brand Reputation

The quality of a brand’s products and packaging frequently determines its reputation. Poor packaging can harm a brand’s image and hurt sales.

Safety Compliance

Certain industries, such as food and pharmaceuticals, must follow stringent safety and regulatory guidelines. It is non-negotiable that labels and packaging meet these requirements.

Marketing and Communication

Packaging is an effective marketing tool for communicating information, branding, and product uniqueness. Labels that are poorly executed can impede good communication.

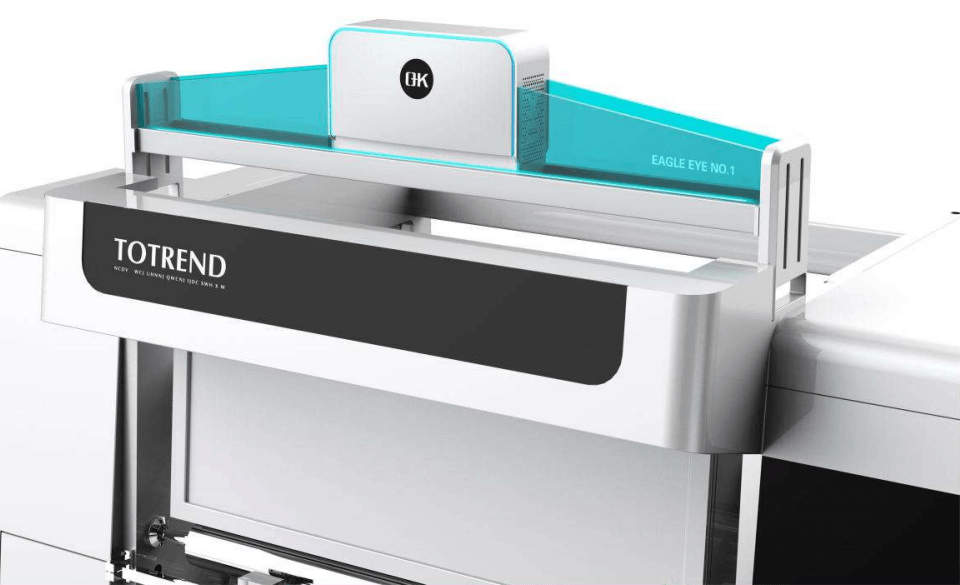

Printing inspection systems are advanced technologies that examine every aspect of labels and packaging. They work with precision and speed, making them indispensable in the packaging industry.

How Printing Inspection Systems Contribute to the Quality and Safety of Labels and Packaging

1. Detecting Defects with Precision

Label and packaging inspection devices rigorously scan for faults that may not be evident to the naked eye. These defects can include misprints, color inconsistencies, streaks, smudges, or even subtle imperfections in graphics or text. By identifying and flagging these issues in real-time, these systems prevent subpar products from reaching consumers, thus upholding quality standards.

2. Ensuring Regulatory Compliance

Regulatory compliance is non-negotiable in businesses like pharmaceuticals and food. Label and package inspection systems are designed to ensure that labels and packaging meet stringent regulatory criteria. They validate the inclusion of critical information such as expiration dates, dosage directions, and legal disclaimers, lowering the risk of noncompliance and associated legal complications.

3. Barcode Verification

Barcodes are an important part of modern packaging since they help with inventory control, supply chain tracking, and product authenticity. Printing inspection systems excel at ensuring barcode accuracy and readability. This functionality reduces errors and ensures that items are properly identified and tracked throughout their lifecycle, so improving both quality and safety.

4. Maintaining Color Consistency

Brand consistency is vital for consumer recognition and trust. Printing inspection systems monitor color accuracy and consistency across labels and packaging, ensuring that brand colors remain uniform. This meticulous attention to detail preserves brand integrity and enhances visual appeal.

5. Security Features Verification

For products requiring security features such as holograms, anti-counterfeiting measures, or tamper-evident seals, printing inspection systems play a critical role in verifying the presence and authenticity of these security elements. This safeguards products against counterfeit threats, enhancing both quality and safety.

6. Text and Content Inspection

For each inspection, a printing inspection system creates complete data logs. These logs not only serve as a record of product quality, but they also provide for product traceability. Manufacturers can quickly identify affected products and take immediate action in the case of a recall or quality issue, ensuring consumer safety.

7. Data Logging and Traceability

A printing inspection system generates detailed data logs for every inspection. These logs not only serve as a record of product quality but also enable traceability. In the event of a recall or quality issue, manufacturers can swiftly identify affected products and take appropriate action, safeguarding consumer safety.

8. Reducing Waste and Costs

Printing inspection systems decrease waste by detecting errors early in the manufacturing process and preventing the manufacture of faulty items. This not only saves resources but also reduces production costs, hence increasing total efficiency.

Conclusion

Printing inspection systems serve as effective equipment, ensuring that every label is perfect, every barcode is accurate, and every package is flawless. They not only protect consumers and uphold brand reputations but also help manufacturers adhere to strict industry regulations. As technology continues to advance, printing inspection systems will only become more sophisticated, further enhancing their role in safeguarding the quality and safety of labels and packaging in diverse industries.