The Integration of Web Guide with Print Inspection Systems

Precision, efficiency, and quality control are extremely important in the printing and manufacturing industries. Web guide systems and print inspection systems are two important technologies that aid in these objectives. Each independently enhances production, but the integration of the two can bring paradigm shifts in how printing operations are carried out. This article focuses on the value of integrating web guide systems with print inspection systems and along with that outlines integration benefits, implementation approaches and future directions.

Understanding Web Guide and Print Inspection Systems

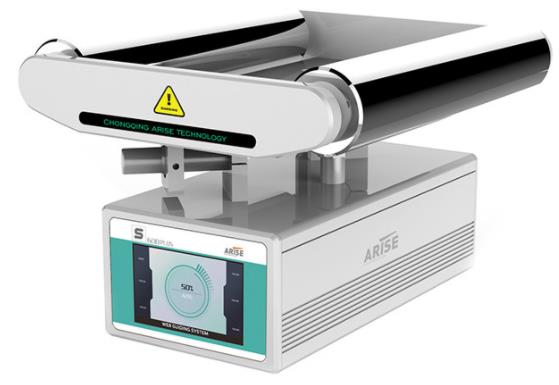

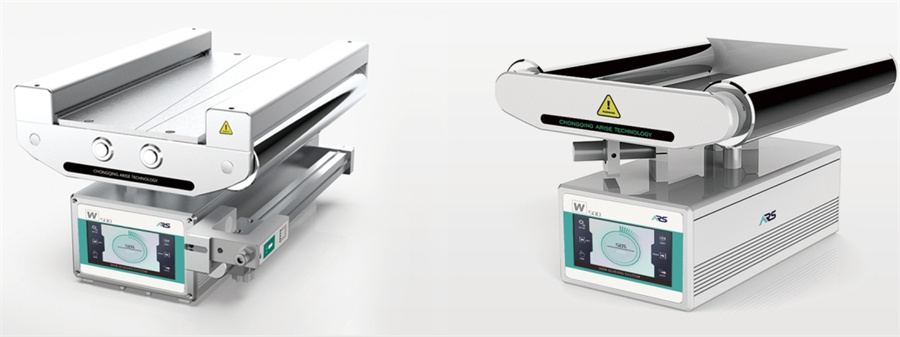

A web guide system ensures the lateral position of a moving web material, whether paper or film or foil, while it is being processed. These systems prevent web misalignment, material and product waste, and quality consistency by automatically detecting web misalignment, and self-correcting web alignment in situ. Each guide system focuses on real-time adjustments and corrections and uses sensors, actuators, and controllers to fix even the smallest of misalignments.

Print inspection systems scan printed material to pinpoint and highlight defects. Components of these systems as high-resolution cameras and imaging software together with AI and machine learning actively controlling the software archive tracking and print quality control, color misalignment, as well as and other remedial actions. By detecting these errors, print inspection systems can control the amount of waste and maintain the quality to a certain level.

Benefits of the Integration of Web Guide with Print Inspection Systems

Improved Print Accuracy

The primary benefit of integration is enhanced print accuracy. Web guide systems keep the lateral alignment of moving materials and the 100% print inspection systems check for defects and misregistrations. Integrated systems sustain feedback mechanisms whereby corrective actions become immediate. Defective prints do not happen because realignment occurs faster than the prints can be misaligned. The output is sustained and of high-quality.

Reduced Material Waste

Integration increases material efficiency. Reprints and scrapped materials because of misalignment and printing mistakes can be avoided. Web alignment changes and real time defect identification help manufacturers conserve paper, film, and ink. Production expenses are reduced as well as sustainable manufacturing practices.

Increased Operational Efficiency

The integrated systems of web guide and printing inspection enable operators to stop focusing on web alignment and print quality as separate processes. The system automatically optimizes and speeds up the processes with one command. Manual work is done away with, and faster, smoother, and less interrupted production lines are created.

Predictive Maintenance and Process Optimization

Analyzing unique data sets generated by integrated systems analyzing web behavior and quality of prints allows manufacturers to forecast problems and take proactive measures by automating machine settings. This form of predictive maintenance helps to minimize costly downtime, helps to sustain process maintenance-perpetual, and aids in continuously improving process workflows.

Enhanced Flexibility and Adaptability

Integration allows production lines to be more adaptable and flexible. Changes to different web materials, printing speeds, and various product configurations can be done in a shorter time. This aids manufacturers in meeting targets on time, lowers rework processes while sustaining quality.

Key Strategies for Integrating Web Guide with Print Inspection Systems

Integrating precise web alignment control with real-time print defect monitoring enables manufacturers to automate processes and adjust to production smarter, faster.

1. Ensuring Sensor and Data Synchronization

Ensuring proper sensor and data synchronization of web guide systems and print inspection systems is one of the fundamental strategies. Timely detection and correction is facilitated by web systems having data and time locked data communications. Accurate calibration, data and low latency processing enables the systems to work as a single entity. The systems can make web adjustments on print defects instantly.

2. Centralizing Control Systems

The integration of the web guide and print inspection systems within the centralized control systems is of utmost importance. Having a control unit that captures the data from both the web guide and print inspection systems minimizes the reliance on human operational control. This protocol reinforces that any corrective measures that are required in the case of misalignment and print defects are collated and worked on, thus promoting efficiency and minimizing human errors.

3. Leveraging Advanced Algorithms and AI

Integration strategies tend to be more effective when using more sophisticated artificial intelligence and algorithms. Using these advanced technologies, a model is able to establish machine learning algorithms that can be utilized to assess historical and real-time data to determine potential errors during the print due to misalignment. Predictive information is able to be utilized to ensure that the system accurately adjusts the web position to limit defects during production, thus increasing production quality.

4. Conducting Comprehensive Calibration and Testing

The precision in integration is highly dependent on the calibration and the testing of the systems. In all the processes integrated with the web guide and print inspection systems, the operational silence clause should be respected at all times. In the normal functioning of the systems, a definite border should be established to ensure that the checks are optimized, the misalignment is maintained alongside the defect, and the reliability within the production run is at its peak. All of these issues should be addressed within the defined parameters to account for any potential web materials, velocity, and the variable such as temperature and humidity.

Challenges in the Integration of Web Guide with Print Inspection Systems

| Challenge | Description | Impact on Operations |

| System Compatibility | Differences in communication protocols and software architectures between web guide and print inspection systems. | Can lead to integration delays, require custom interfaces, and increase implementation costs. |

| Data Overload | High-resolution cameras and fast-response sensors generate large volumes of data. | May cause slower processing, delayed corrections, and require robust storage and computing resources. |

| Calibration Complexity | Ensuring both systems operate in sync without introducing new errors. | Incorrect calibration can result in misalignment, missed defects, or false alerts. |

| Real-time Response Requirements | The need for immediate communication between sensors and actuators. | Delays can reduce defect correction efficiency and increase material waste. |

| Maintenance and Technical Training | Integrated systems are more complex than standalone units. | Higher training requirements and potential for prolonged downtime if issues arise. |

| Environmental Sensitivity | Web materials and sensors can be affected by temperature, humidity, and vibration. | May lead to inconsistent performance and require frequent recalibration. |

| Cost of Implementation | Integration often requires advanced controllers, AI software, and synchronization devices. | Increases upfront investment and may limit adoption for smaller operations. |

Future Trends in the Integration of Web Guide with Print Inspection Systems

There continues to be new development in technology and new emerging trends coming up that involve in integrating web guide with print inspection systems, aiming at evolving the systems to enable smarter, sustainable, and more automated production.

1. Smart Manufacturing and Industry 4.0

The integration of Industry 4.0 is a defining factor in the evolution of web guide and print inspection systems. By linking devices, control systems, and machines to the Internet of Things (IoT), manufacturers can perform real-time data sharing and process automation. This integration allows for immediate feedback and real-time adjustments to web alignment based on print quality feedback, shifting the production line to be more automated and intelligent.

2. AI-Driven Predictive Analytics

Artificial intelligence (AI) and machine learning technologies are becoming more and more pivotal in predictive web guide and print inspection system analytics. Predictive analytics can determine potential printing defects in real-time that are associated with web misalignment or web material inconsistencies. This enables systems to optimally correct the potential errors beforehand, thus, eliminating wastage of resources and improving the yield of a quality product.

3. Enhanced Real-Time Monitoring

There is an expectation that systems of the future will enable even real-time monitoring that is more precise. Instantaneous detection and recognition of misalignment and defects and (with the aid of) high-speed and sensors, and low-latency data processing will ensure that corrective measures are employed on time. This will alleviate material wastage and downtime on the system.

4. Cloud-Based Data Management

With integrated systems being adopted throughout the manufacturing industry, cloud computing is set to have an important impact. With a centralized cloud platform, manufacturers can store, analyze, and access data from anywhere, which supports more advanced analytics. In addition, the cloud enables remote monitoring, system maintenance, and web guide and print inspection system maintenance, as well as system optimization.

5. Cross-Platform Integration and Standardization

Standardization of communication protocols and the interfacing of software will facilitate integration of disparate systems of varied manufacturers. This development will enhance the ability of print operations to implement integrated solutions, mitigate integration problems, and improve the adaptability of production lines.

6. Sustainability and Waste Reduction

The growing importance of the environment means that more integrated systems will focus on sustainable operations. Less alignment and print defects can mitigate the paper, ink, and energy used in the manufacturing process. Moreover, integrated systems offer predictive maintenance, which can decrease unnecessary resource usage and extend the lifespan of a machine.

7. Autonomous and Self-Optimizing Systems

The fully autonomous and self-optimizing production lines is the integration goal of the next generation. Complete sovereignty over web alignment and print parameters will be achieved using the synergistic technologies of IoT, AI, and cloud analytics. This will enhance efficiency, lower the error margins, and foster lean manufacturing.

Summary

The integration of web guide systems with print inspection systems is a breakthrough addition to the printing and manufacturing industry. With web alignment and instantaneous print quality monitoring, manufacturers can realize higher productivity, minimized waste, and excellent quality. With the further advancement of technology, integrated systems will be more crucial in supporting smart, sustainable, and ultra-efficient production systems.