What are the Key Components of A Web Inspection System for Printing Quality: Meeting High Standards for the Final Products

Web inspection systems serve a critical role in ensuring that the final output satisfies the highest requirements in the dynamic world of printing, where quality is crucial. A web inspection system for printing quality is designed to inspect every detail of the printing process, finding faults and anomalies that could jeopardize overall quality. This essay goes into the major components of a web inspection system for printing quality, shedding light on the complex elements that contribute to printing perfection.

Working Principle of a Web Inspection System for Printing Quality

A web inspection system for printing quality is based on the real-time capture, analysis, and categorization of pictures from the printed web. This technology is intended to detect and identify printing faults or inconsistencies, guaranteeing that the final printed content satisfies high-quality standards.

Key Components of a Web Inspection System for Printing Quality

1. Camera Systems

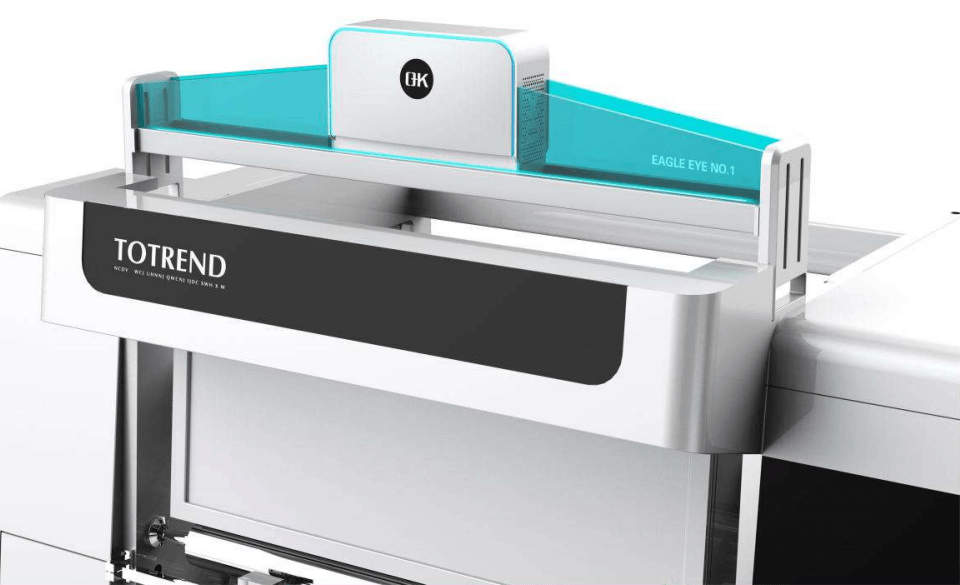

High-resolution camera systems are at the heart of a web inspection system. In real time, these cameras collect detailed photographs of the printed material. To achieve precise and complete picture capture, modern web inspection systems frequently combine advanced camera technologies such as high-speed line scan cameras or high-resolution area scan cameras.

2. Illumination Systems

Proper lighting is required for accurate fault detection. In web inspection, illumination systems are precisely built lighting settings that illuminate the surface of the printed web. This aids in uncovering flaws such as color fluctuations, misregistration, or substrate problems.

3. Conveyor System

A robust conveyor system moves the web of printed material at a predetermined speed through the inspection zone. For reliable examination, web movement must be consistent and exact.

4. Image Processing Software

The captured images are processed using sophisticated image processing software. This software employs algorithms to analyze the images, identify defects, and categorize them based on predefined criteria. Machine learning and artificial intelligence may be integrated into the software for adaptive defect recognition.

5. Defect Classification Algorithms

Defect classification algorithms are critical for distinguishing between acceptable variations and actual defects. These algorithms are trained to recognize patterns associated with common printing defects, such as misprints, color deviations, streaks, or registration errors.

6. User Interface and Control System

The user interface is the bridge between the operator and the inspection system. It displays real-time photos and allows operators to customize inspection parameters while providing a graphical description of the inspection process. Operators can use the control system to start, halt, or change the inspection process as needed.

7. Defect Marking System

Once defects are identified, a defect marking system is used to highlight or mark the defective areas. This aids operators in pinpointing and addressing specific issues during the printing process. Some systems may integrate automatic defect marking features for enhanced efficiency.

8. Integration with Printing Press

A web inspection system must be linked with the printing press for smooth operation. This integration ensures synchronized control, allowing the inspection system to adjust to variations in printing speed, modify lighting conditions, and stay in sync with the printing process.

9. Data Logging and Reporting

Comprehensive data logging capabilities enable the system to record inspection results, including defect types, frequencies, and locations. Reporting tools allow operators to generate detailed reports for analysis and quality control purposes.

10. Remote Monitoring and Control

Some advanced web inspection systems allow for remote monitoring and control. This enables personnel to monitor and change the inspection process from a remote location, increasing operational flexibility.

Conclusion

A web inspection system contributes to the overall quality and consistency of the printed material, guaranteeing that flaws in the printing process are recognized quickly by combining advanced imaging technology, clever software algorithms, and real-time monitoring, whichl. The system’s real-time nature enables fast remedial actions, reducing waste and ensuring that the final output satisfies high-quality standards.