Why Choose Retrofitting Older Machine with Web Tension Control Systems

In today’s fast-paced industrial world, efficiency, productivity, and cost-effectiveness are more important than ever. To meet production demands, manufacturing processes, particularly in industries such as printing, packaging, and textiles, sometimes rely on older gear. While these machines are still operational, their lack of current features and technology might reduce productivity and quality. Retrofitting older machines with web tension control systems is a realistic alternative for bridging the past and the present and bringing outdated equipment up to modern standards.

The Importance of Retrofitting Older Machines with Web Tension Control Systems

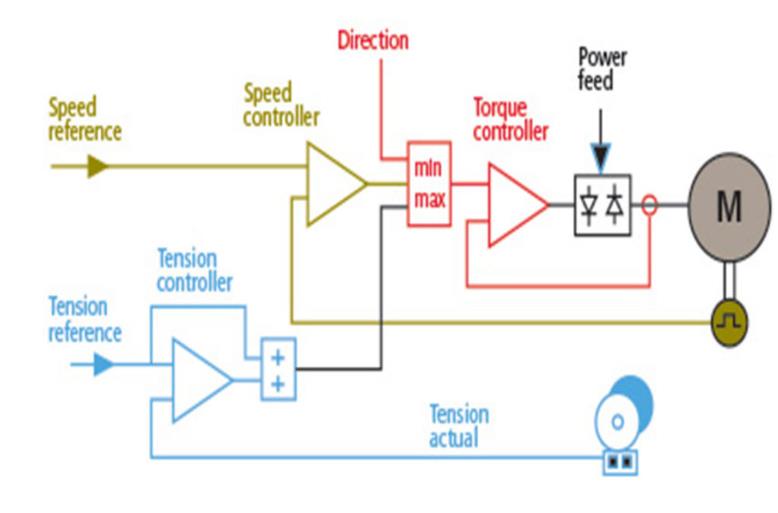

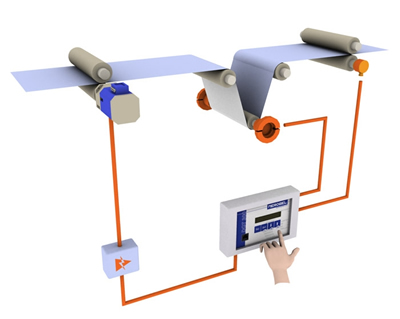

Web tension control is a critical aspect of various manufacturing processes that involve continuous materials, such as paper, film, fabric, or metal. Proper tension control ensures the consistent and accurate movement of materials through a machine, which is essential for product quality, waste reduction, and minimizing downtime.

Benefits of Retrofitting Older Machines with Web Tension Control Systems

Improved Product Quality

Consistent web tension results in fewer faults and higher-quality goods, enhancing your company’s reputation and client satisfaction.

Enhanced Efficiency

Reduced downtime and faster production rates lead to increased overall efficiency, which has a direct influence on your bottom line.

Cost Savings

Less waste, fewer maintenance costs, and higher energy efficiency all contribute to cost savings and profitability.

Sustainability

Reduced waste and energy consumption save money while also making your operations more environmentally friendly and sustainable.

Prolonged Machine Life

Retrofitting can extend the life of aging machinery, putting off the need for expensive replacements.

Data-Driven Decision Making

Modern tension control systems give useful data and analytics that enable better decision-making and process optimization.

The Retrofitting Older Machine Process with Web Tension Control Systems

1. Assessment

Begin by thoroughly evaluating your current gear and determining the particular places where web tension control is crucial to your production process.

2. System Selection

Choose a web tension controller that meets your needs, taking into account elements such as web material, machine specs, and production speed.

3. Installation

It is critical that the system be installed by professionals who are familiar with the complexities of combining current control systems with older equipment. Mechanical and electrical changes may be required to assure compatibility.

4. Calibration

Calibrate the system to provide exact tension control, which normally entails establishing sensors, creating tension zones, and modifying control settings.

5. Training

Train your operators and maintenance workers to operate and manage the tension control system efficiently.

6. Integration

Integrate the new web tension control system into your existing control infrastructure, such as PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control and Data Acquisition) systems, for seamless communication and data exchange.

Case Studies of Retrofitting Older Machines with Web Tension Control Systems

Case Study 1: Printing Industry

Company: ABC Printing Company

Challenge: ABC Printing Company had been using an aging web offset printing press for several years. Despite its reliability, the press lacked precise web tension control, leading to inconsistent print quality and frequent paper jams. This not only resulted in a high rate of product defects but also increased downtime, causing delays in meeting customer deadlines.

Solution: ABC Printing Company made the decision to replace their antiquated printing press with a new web tension control system. They performed a thorough evaluation of their equipment and selected a cutting-edge tension control system that could fit easily with their existing setup. Professional technicians installed the system, adjusted it to meet their specific printing needs, and trained its operators.

Results: The retrofit had a significant impact on ABC Printing Company’s operations:

Improved Product Quality: Printing quality improved significantly with continuous web tension control, resulting in a 40% reduction in product faults and customer complaints.

Increased Productivity: Downtime due to paper jams decreased by 60%, leading to a 25% increase in production speed. This allowed ABC Printing Company to take on more orders and meet customer deadlines more effectively.

Waste Reduction: The reduction in paper jams and misprints led to a 30% decrease in material waste, contributing to significant cost savings.

Simplified Maintenance: The modern control system was easier to maintain and troubleshoot, reducing maintenance costs by 15%.

Case Study 2: Textile Industry

Company: XYZ Textile Mills

Challenge: XYZ Textile Mills, a manufacturer of various textile products, was facing challenges with their weaving looms. Because early looms lacked precise web tension control, yarn breakage, misalignment, and variable fabric quality were common. These concerns resulted in greater downtime and a decrease in product quality.

Solution: XYZ Textile Mills opted to retrofit their weaving looms with modern web tension control systems. They conducted a thorough evaluation of their looms and selected a tension control system that could be seamlessly integrated into their textile manufacturing process. The installation was carried out by experienced technicians, and operators received training on using and maintaining the new system.

Results: The retrofit had a transformative effect on XYZ Textile Mills’ operations:

Enhanced Fabric Quality: With consistent web tension control, the looms experienced a 30% reduction in yarn breakages and misalignments, leading to a 25% improvement in fabric quality.

Increased Productivity: Reduced downtime and fewer fabric defects resulted in a 20% increase in production speed, allowing XYZ Textile Mills to fulfill orders more efficiently.

Cost Savings: The reduction in yarn breakages and improved quality reduced material waste by 20%, contributing to cost savings.

These case studies exemplify how retrofitting older machines with modern web tension control systems can have a transformative impact on product quality, productivity, cost savings, and sustainability, making it a wise investment for many manufacturing businesses.

Conclusion

For companies wishing to improve the efficiency and productivity of their existing production processes, retrofitting older machines with web tension control systems is a strategic and cost-effective solution. This web tension control method assures that your aging machinery can compete with modern machinery, resulting in improved product quality, less waste, and overall cost savings. You can maintain your manufacturing operations competitively by carefully assessing your machinery, selecting the appropriate control system, and investing in competent installation and training.