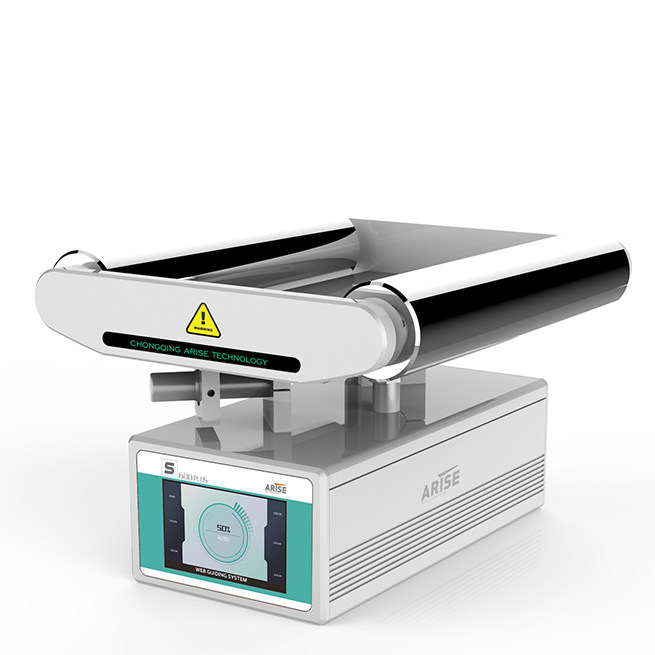

Why Choose Web Guide System to Improve Accuracy and Quality in Paper Manufacturing

A sophisticated technology, web guide system, ensures accurate alignment and control of the paper web throughout the manufacturing process. It is an automated system that aids in the alignment and control of the movement of the paper web as it progresses through the manufacturing process. This technology improves accuracy, reduces waste, increases productivity, and improves end-product quality by eliminating web variations and preserving optimal alignment. In this article, we will discuss the topic of why choose web guide system to improve accuracy and quality in paper manufacturing, exploring the working, benefits and key applications of web guiding system in paper manufacturing.

How Web Guide System Works in Paper Manufacturing

Here’s how web guide system works:

Detection

The web guide sensor monitors the position of the paper web in real-time and detects any deviations from the proper alignment. This data is sent to the control system.

Analysis and Calculation

The control system analyzes the sensor data and calculates the necessary modifications to bring the web back into alignment. It takes into account factors such as web speed, tension, and desired alignment specifications.

Adjustment

Once the control system has determined the necessary modifications, it transmits signals to the actuator. The actuator then moves the web guide mechanism, such as rollers or guides, to rectify the web deviation and bring it back on track.

Continuous Monitoring and Feedback

The web guide sensor continues to monitor the position of the web, delivering real-time feedback to the control system. This continual monitoring and correction mechanism ensures that the web remains aligned throughout the production process.

What are the Benefits of the Web Guide System in Paper Manufacturing

Improving Web Alignment

The enhanced alignment of the paper web is one of the main advantages of the web guide system. It guarantees that the web remains in the desired position during the manufacturing process, reducing web variations and misalignments. This results in more accurate printing, coating, and cutting, resulting in higher-quality end products.

Enhancing Productivity

The web guide system increases production speeds without sacrificing precision by preserving optimal web alignment. It reduces the need for human corrections and allows the manufacturing process to function smoothly and efficiently by minimizing downtime caused by web misalignment. As a result, productivity and output rise.

Waste Reduction

Paper waste can come from web irregularities and misalignments. Misaligned parts may have to be scrapped, which increases material costs and has an environmental impact. The web guide system reduces waste by keeping the entire paper web aligned and useful. This eliminates material waste and helps to make production more sustainable.

Improving Quality Control

The overall quality of the ultimate result is directly influenced by accurate web alignment. Precision alignment assures accurate and uniform results throughout the production process, whether printing, coating, or cutting. This results in higher-quality paper goods that meet client expectations and boost the manufacturer’s reputation.

Cost Savings

For paper manufacturers, implementing a web guide system might result in significant cost reductions. Manufacturers can cut manufacturing costs by lowering waste, increasing productivity, and reducing the need for manual adjustments. Furthermore, the system optimizes material usage, resulting in higher resource efficiency and long-term cost reductions.

Reducing Downtime

Misalignments and variations in the web might result in frequent production pauses and downtime. The web guide system prevents such problems by constantly monitoring and modifying the web position in real time. This decreases the need for manual intervention and downtime, allowing for continuous production and increased operational efficiency.

Flexibility and Versatility

The web guide system is intended to work with a variety of paper types, sizes, and weights. It is simple to incorporate into current production lines and may be tailored to meet individual manufacturing needs. This adaptability enables producers to respond to changing paper products and manufacturing demands, increasing overall versatility and reactivity.

Operator-Friendly

User-friendly interfaces and easy controls are standard features of web guide control system. Operators can easily monitor and adjust the system parameters as needed, facilitating efficient operation and reducing the learning curve for new users. This improves overall operator satisfaction and effectiveness.

What are the Key Applications of the Web Guide System in Paper Manufacturing

The web guide system is a critical component in paper manufacturing, offering a wide range of applications that contribute to the overall efficiency and quality of the paper manufacturing process.

Web Alignment

The web guide system’s major function is to ensure exact web alignment throughout the production process. It regulates the lateral movement of the paper web, ensuring that it is correctly positioned and aligned with the desired course. This is critical for several steps of paper manufacturing, such as printing, coating, cutting, and converting.

Printing

The web guide system is critical in the printing process for maintaining precise registration and alignment of the paper web. It ensures that the printing plates or cylinders are positioned precisely in relation to the web, resulting in sharp and well-aligned printed images. This use is very useful in high-quality printing, such as periodicals, catalogs, and packaging materials.

Coating

Coating is a common technique in paper manufacturing that involves applying a layer of coating material to the paper web to improve qualities such as smoothness, gloss, and printability. The web guide system guarantees that the web is precisely aligned during the coating process, resulting in uniform and consistent coating application. This produces a high-quality coated paper with even coating material dispersion.

Slitting and Cutting

Slitting and cutting procedures are required to turn the paper web into different sizes and forms. The web guide system ensures straight and precise cuts by maintaining proper web alignment during slitting and cutting operations. This software is essential for generating paper rolls, sheets, or specific paper goods with regular dimensions and precise trimming.

Tension Control

The web guide system also aids in tension control during the papermaking process. It guarantees that the correct tension levels are maintained in the web, preventing wrinkles, creases, and sagging. Maintaining the integrity of the paper web and preventing quality concerns during future processing stages requires proper tension control.

Edge Guiding

Edge guiding is another key application of the web guide system, in which it controls the lateral position of the paper web relative to a reference edge or guide. This is especially beneficial in procedures requiring precise edge-to-edge registration, such as folding, laminating, or perforating. The web guide system maintains the paper web’s alignment with the reference edge, resulting in accurate and consistent finished goods.

Web Monitoring and Inspection

Web monitoring and inspection capabilities are built into several powerful web guide systems. They use sensors and cameras to identify faults in the paper web, such as holes, tears, or color differences. This enables producers to detect and address quality concerns in real time, guaranteeing that only defect-free paper advances through the manufacturing process.

Process Optimization

The web guide system contributes to overall process improvement in paper manufacture, in addition to specific applications. It facilitates smoother and more effective production by maintaining accurate web alignment and managing tension, reducing waste, downtime, and manual interventions. The system captures web position and performance data, which provides significant insights for process analysis and optimization.

Summary

Web guide system is an essential technology in paper manufacturing, providing numerous advantages. This web guiding technology enhances the overall efficiency and performance of paper manufacturing operations by ensuring the exact alignment of the paper web throughout the manufacturing process.