How to Customize Web Guide Systems for Different Materials

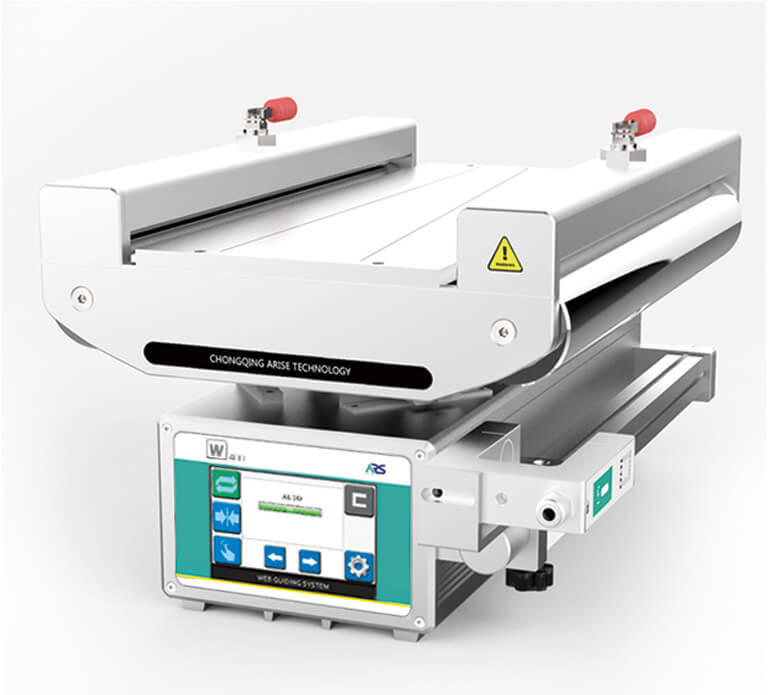

Precision and efficiency are essential in modern manufacturing, especially in industries dealing with continuous web materials like paper, film, textiles, and metal foils. Alignment, waste minimization, and quality improvement are core functions of web guide systems. Still, due to the challenges different materials present, Customizing web guide systems is critical to achieving optimal performance.

Table of Contents

Challenges in Web Guiding Different Materials

This chart provides the main challenges that manufacturers face when trying to maintain precise alignment for different materials during web guiding operations.

| Material Type | Key Challenges in Web Guiding |

| Thin Films | Highly sensitive to stretching and tearing; low friction may cause slippage; prone to wrinkling under tension |

| Textiles | Elasticity and flexibility cause lateral drift; surface irregularities can affect sensor detection; risk of stretching or distortion |

| Paper | Varies in stiffness and thickness; moisture content can affect tension; prone to edge damage and wrinkles |

| Metal Foils | Heavy and rigid; high tension needed for alignment; difficult to correct lateral deviations quickly |

| Plastic Sheets | Static charge accumulation may interfere with sensors; flexible yet prone to edge defects under misalignment |

| Laminates | Multiple layers with differing properties; uneven tension distribution can cause delamination or wrinkles |

| Adhesive Tapes | Stickiness can disrupt rollers; tendency to stretch or skew; edge buildup may affect sensor performance |

The Importance of Customizing Web Guide Systems for Different Materials

Web guide systems are customized to solve issues that different materials present. Sophisticated materials may require customized sensors, actuators, and guiding mechanisms to hold and align the material. For dynamic control of web alignment, the combination of static systems with fast-acting actuators, which provide responsive overall process stability, is essential. Enhancements like micromaterial adjustments on the web and control equipment are also critical in wear reduction.

Key Considerations in Customizing Web Guide Systems for Different Materials

Understanding the key considerations in the process of customizing web guiding system is critical for maximizing performance and operational efficiency.

1. Understanding Material Properties

To analyze and understand material properties, first think of the thickness, stiffness, elasticity, texture, and the friction of the material. Different materials have different thickness, stiffness, elacticity, texture, and friction, and these differences must be accounted when material is being processed. When handling thin sheets or lightweight textiles, the guiding devices must be gentle and low pressure. This is necessary to avoid stretching, tearing or distortion of the material. On the other end of the spectrum, thick and stiff materials, like metal foils, require guiding devices that are able to deal with robust metal control and alignment guiding devices under high tension. The friction of the surface affects the control of the guiding devices. Hence, the choice of sensors and the design of rollers must account for the friction surface of the material being processed.

2. Web Width and Speed

Guiding consisted of fast manipulation of large sheets of material and processing speed automation and the operational width have friction characteristics of the web material and its surface also influence the design of the guiding system Correcting offsets in the guiding system. The guiding system must be adjusted to fit the speed of processing in order to maintain the alignment of the web.Less control is required with low speeds of processing or narrower width of material, but adjustments must be made to the guiding system in order to avoid defects that would cause variations in the material being processed.

3. Tension Control and Feedback Systems

Appropriate tension affects both the quality of a product and the integrity of the web. Wrinkles, stretches, and breakages occur when there is too little or too much tension. Some custom web guide systems include dynamic tension control systems, which monitor systems passively or control systems actively. With elastic or sensitive materials, misalignment on the order of millimeters is unacceptable and will break the web if not properly controlled.

4. Sensor and Actuator Selection

Another important variable is the selection of the right sensors and actuators. Selection of optical, ultrasonic, or edge detection sensors is made considering the transparency and reflectivity of the material as well as the surface finish. The type of actuators (pneumatic, hydraulic, or electric) is also important as they must balance speed, force, and accuracy to realign the web, which can cause misalignment as well. The material type must be well-understood at the sensor and actuator for precise guidance to be confirmed and variable adjustments to be controlled.

5. Integration with Production Equipment

A web guide system must also be integrated with the systems before and after it; otherwise, it will cause web breaks, downtime, and excessive maintenance. Integration is a customization task for the guide system, which allows for a continuous flow of production and operational downtime. This is critical to ensure maintenance is unplanned as much as possible.

Benefits of Customized Web Guide Systems

| Benefit Category | Description |

| Improved Product Quality | Precise alignment reduces edge damage, wrinkles, and defects, ensuring consistent output |

| Reduced Material Waste | Accurate guiding minimizes scrap, web breaks, and misalignment, saving material costs |

| Enhanced Operational Efficiency | Automated correction and real-time adjustments reduce manual intervention and downtime |

| Optimized Tension Control | Tailored tension management prevents stretching, distortion, and delamination in sensitive materials |

| Extended Equipment Life | Matching guide components to material requirements reduces wear on both the web and the system |

| Material-Specific Handling | Custom web guiding rollers, sensors, and actuators accommodate the unique properties of each material type |

| Seamless Integration | Ensures smooth communication and coordination with upstream and downstream production equipment |

Emerging Trends in Customizing Web Guide Systems for Different Materials

Due to the advancement in manufacturing needs, the customization of web guiding control systems has become more elaborate to manage diverse materials at higher speeds and with more precision.

1. Advanced Sensor Technologies

A growing trend in customization of web guide systems is the integration of more sophisticated sensing technologies to enhance the systems’ responsiveness and detect even the most minute lateral shifts of the web. Optical web guide sensors, laser sensors and ultrasonic edge sensors are becoming increasingly sophisticated and not as easily fooled by transparent and highly reflective materials. The highly accurate and responsive sensors shortening the correction cycles in the systems reduce the overshoot and enhance waste control when switching between different materials.

2. Intelligent Actuation Systems

There is no shortage of innovation in the automated control of web guide systems. Linear control systems, responsive to electrical or servo motors, are becoming the standard for new web guide systems. The systems combine precision sensing and motor control to automate web alignment. Systems that employ predictive control, to entirely remove system response to realignment triggers, are becoming the standard for sensitive materials like films and flexible textiles, and even for heavy and less flexible materials like metal foils.

3. AI and Machine Learning Integration

Artificial intelligence and machine learning use innovative techniques for tailoring web guiding automation and use AI systems to optimize control of web tension, actuators, and guides by assessing historical performance data and real time sensor data. This closed control loop automation facilitates learning of various materials thereby improving automation and reducing manual intervention for adjustments over time.

4. Material-Specific Customization

The trend within manufacturing has shifted toward more material-specific customization and away from the traditional one-size-fits-all approach. This new integrated web guide systems can be designed with adjustable rollers, coatings, and sensor sets, which can be configured as a quilt cover to specifications pre-defined by the material’s properties. This will ensure that the more delicate materials are handled more gently while rigid or heavy materials are aligned and tensioned during the production process. This will improve the consistency of the operational tasks and the quality of the final products.

5. Enhanced Integration with Production Lines

Modern web guide control systems are designed with the ability to communicate with adjacent systems. Seamless integration with production systems enables aligned automated adjustments and reduces web breaks or misalignments. This integration of systems allows uninterrupted and continuous production, even under complex or multiple materials, layers, or webs.

Summary

With the rise of manufacturing processes that deal with a wider variety of materials at advanced rates, the reasonable need for customizing web guide systems becomes more acute. This customized solution facilitates the mastery of the essential parameters of each material: flexibility, surface structure, tension and operational speed. Such mastery of the parameters leads manufacturing processes to achieve steady product quality, optimizing product value and attaining the desired operational efficiency. Customized web guiding solutions are primary and strategic for the production to be competitive and of high performance.