Camera vs. Sensor Technologies in 100% Print Inspection Systems

Implementing 100% print inspection systems is a great way to maintain quality in printing operations, as these systems automatically monitor and review the output of print jobs in real-time. Such systems use sophisticated imaging tools. Mostly, these printing inspection systems use cameras and sensors to spot imperfections, contradictions, and anomalies. We will discuss the comparison of the use of camera and sensor technologies in 100% print inspection systems, the advantages and disadvantages of each, as well as the particular situations in which each surpasses the other.

Table of Contents

Understanding Camera Technologies in 100% Print Inspection Systems

In print inspection systems, the most common type of camera technology is line-scan cameras, which are tailored for high speed and continuous use. As the printed materials progresses along the production line, these cameras capture the images facilitating a real-time inspection of the complete print output.

Key Features

- High Resolution: High-resolution cameras adopt high-definition imaging offering adequate capturing the most minute details in every printed component.

- Color Sensitivity: Cameras tend to discrimination over five shades of color in the printed materials for color reproduction to align within the intended reproduction.

- Speed: Line-scan cameras can inspect the printed materials in a fraction of a second as they move along the production line making these cameras ideal for high speed printing.

Advantages

- High Resolution and Detail: Camera technologies stand out because of their ability to capture high-quality images. Even the minute defects, such as misprints, color mismatches, blurring, and irregularities of the surface, are exposed. Such surface blemishes may go unnoticed against other types of inspection technologies.

- Color Accuracy and Print Quality: In color fidelity assessment of printed materials, cameras, more so multispectral and RGB cameras, play crucial industry roles. Print materials in some industries require stringent and consistent color assessment. Such cameras expose color shifts, ink coverage omissions, misalignments, and registration errors which the eye of an operator may overlook.

- Real-Time Monitoring and Feedback: Cameras are critical to high-speed printing operations because they capture images in real-time during production. This ability to provide feedback during the print run enables the operator to identify defects and enact corrective measures, thereby creating an opportunity to prevent an entire print run of defective materials.

- Inspection of Complex Print Patterns: In the inspection of complex print patterns and intricate designs which are common in the textile industry and security printing industries, cameras excel. They are able to capture fine text, intricate logos, and detailed graphics, and identify defects in these complex print components which other technologies may struggle.

- Customizable and Flexible: Depending on the type of camera and its specifications, a range of camera systems can be adapted and tailored for different print inspection requirements. These systems can accommodate the assessment of various printed materials, from straightforward text, intricate graphic designs, to even holographic security features.

Limitations

- High Cost: Cost stands out as the foremost drawback of camera print inspection systems. Line-scan cameras with high resolution and advanced functionalities like color discrimination and multi-channel imaging are expensive both to purchase and maintain. Cost increases significantly if multiple cameras are deployed to monitor a large printing surface.

- Complex Setup and Calibration: Compared to other inspection systems, the camera setup, as well as the integration with the printing system, entails more complex and cumbersome processes. While the cameras must be aligned with the print process, software settings that differentiate acceptable prints from defects also need considerable calibration. This process requires considerable expertise and time to configure appropriately.

- Lighting Sensitivity: Cameras need optimal and sometimes customized lighting to produce the necessary image resolution for analysis. Defect detection can be impaired if printing systems produce complex configurations to masks and the lighting situates shadows or reflections on the print.

- Large Data Processing Requirements: High-resolution cameras take a lot of data when inspecting high-speed, big-size printed materials and continuous data flow needs to be processed to identify defects in real time, which requires a lot of high-powered computing and advanced software.

- Environmental Conditions: Environmental conditions, such as dust, moisture, and temperature fluctuations, can affect the functioning of the camera systems. Dust on camera lenses and image sensors can blur pictures and reduce inspection precision.

Understanding Sensor Technologies in 100% Print Inspection Systems

Sensors used in 100% print inspection systems typically rely on detecting changes in physical properties of the printed material or the printing process. These sensors may include:

- Optical sensors (varying light, reflectivity and color)

- Capacitive sensors (material thickness and surface finish)

- Ultrasonic sensors (internal defects)

- Laser sensors (registration and alignment in printing and controlling distance and shape)

- Inductive sensors (act of controlling metal or conductive material in printed design)

Although cameras aim to capture pictures, sensors, in contrast, receive data that shows changes in a solid, and their data on the environment comprises the quality of control systems.

Advantages

- Speed and Real-Time Monitoring: Within the context of the printing process, sensors can detect changes in the properties and alignment of various components. The precision and immediacy response to potential faults in the production process of printing materials makes sensors appropriate for environments in which large-scale production and rapid error correction are critical.

- Cost-Effectiveness: When sensors are used for inspection and monitoring, one is able to save on cost investments, considering that high resolution cameras are much more expensive than sensors. Businesses that want to monitor the quality of their production processes can use camera-less inspection sensors to save on costs, while still maintaining their quality control.Less Susceptible to

- Environmental Variability: Unlike camera systems, sensors do not rely on illumination. In industrial applications, variability occurs in the illumination, and the surface of the materials being printed and even in the image that is printed. Because of this variability, sensors are more reliable than cameras.

- Non-Visual Detection: While cameras excel at identifying visible defects (like misprints or color inconsistencies), sensors detect non-visual defects that are often impossible to see with the naked eye. For instance, capacitive sensors can measure material thickness, ultrasonic sensors can identify internal voids, and laser sensors can detect misalignment or skewing in printed patterns or labels.

- Ease of Integration: Sensor systems are often easier to integrate into existing production lines than cameras, as they do not require as much setup or complex calibration. Sensors can be easily adjusted or swapped out for different applications, making them highly flexible.

- Long-Term Durability: Sensors, especially those used in harsh environments (like capacitive or inductive sensors), tend to be more durable over time than camera systems, which may be prone to wear due to the sensitivity of lenses and image sensors.

Limitations

- Limited Defect Detection Range: While sensors are highly effective for detecting certain types of defects (such as misalignment, thickness variations, or surface inconsistencies), they lack the visual detail that cameras provide. Sensors are unable to detect subtle print defects that are visible to the naked eye, such as color variations, fine text errors, or graphic distortions.

- Dependence on Physical Properties: sensors will only be capable of capturing value limited by the physical characteristics they measure. For instance, an alignment laser sensor will be unable to measure whether the printed colors align, whether intricate details are captured, or even whether it is a printed illustration or photograph.

- Susceptibility to Wear and Tear: Direct contact with the material (e.g., inductive or capacitive) sensors may be subject to degradation or wear. Such reduction in value will trigger the need for recalibration maintenance.

- Limited Data and Analysis: Sensors may provide useful data that pertains to the physical characteristics of the printed material. However, they fail in comparison to the analysis provided by a camera. Cameras document visual data for a range of analyses, including defect categorization, an assessment of color consistency, and much more.

A Comparative Analysis of Camera and Sensor Technologies in 100% Print Inspection Systems

| Criteria | Camera Technologies | Sensor Technologies |

| Defect Detection | Detects visual defects such as color inconsistencies, misprints, and pattern distortions. | Detects physical defects such as thickness variations, misalignment, and surface inconsistencies. |

| Resolution | High-resolution, capable of detecting fine details like small misprints, color shifts, and fine text issues. | Limited to detecting physical properties and non-visual defects; cannot identify subtle visual defects. |

| Cost | High cost due to high-resolution imaging, processing, and complex setup. | Generally more cost-effective with lower installation and maintenance costs. |

| Real-Time Feedback | Provides real-time feedback, but requires more processing power and can experience delays with large data volumes. | Provides real-time feedback with minimal delay; faster response times for defect detection. |

| Data Output | Provides rich, detailed visual data that can be analyzed for defect classification and color consistency. | Provides quantitative data, often focusing on physical properties rather than visual attributes. |

| Application Suitability | Best for detecting complex visual defects, such as in packaging, textiles, or printed graphics. | Best for detecting physical defects, misalignment, and surface quality, such as in labeling or material thickness verification. |

| Setup and Calibration | Complex setup and calibration requiring expertise for alignment and lighting conditions. | Easier to set up and integrate into production lines, with simpler calibration processes. |

| Durability | Sensitive to environmental conditions (dust, moisture), requiring careful protection. | Generally more durable, particularly in harsh environments with fewer moving parts. |

Key Factors to Consider for Choosing Between Camera and Sensor Technologies in 100% Print Inspection Systems

Selecting camera or sensor technologies when implementing a 100% full-surface printing inspection system is vital to achieving superior quality, high speed and cost-effectiveness.

1. Defect Type and Detection Requirements

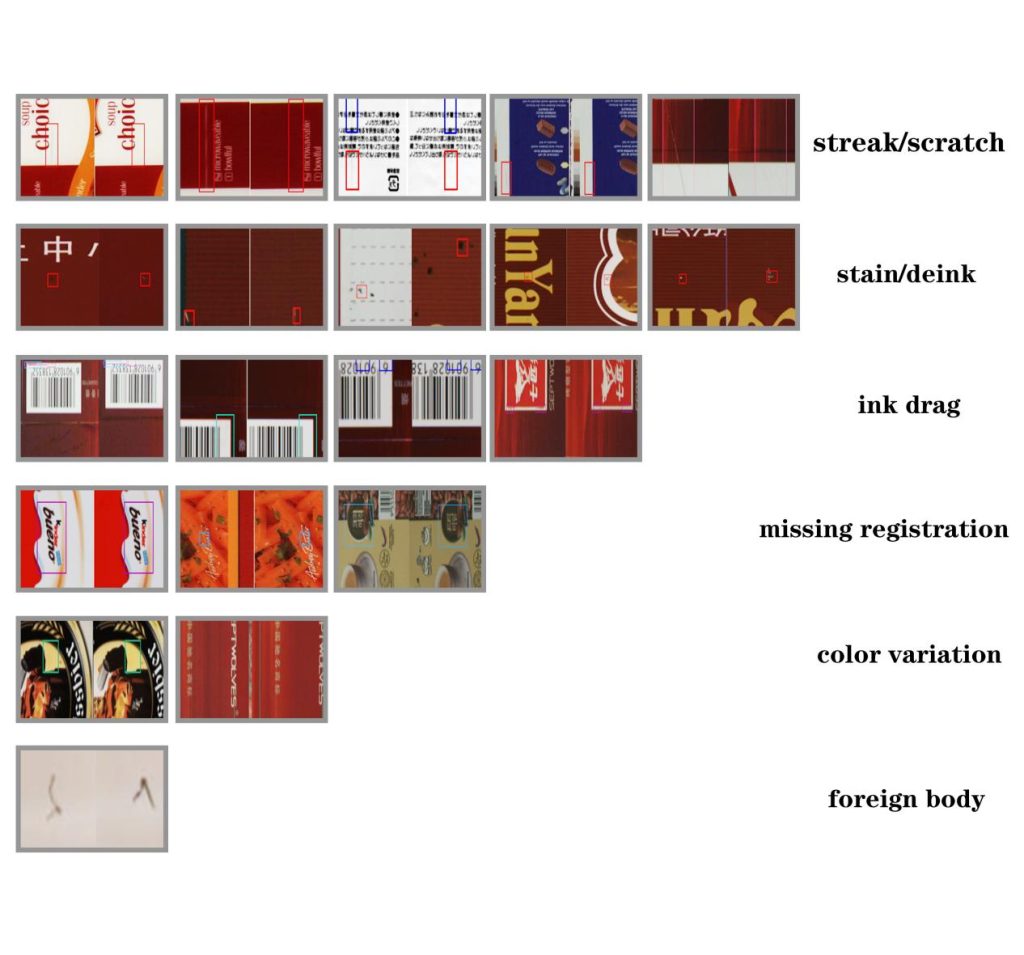

Identifying the type of defect to be inspected must be considered first. Visual defects like color mismatches, printing errors, ink splatters, and design intricacies can be inspected using camera technology. Cameras are useful in identifying the defect that is visible to the naked eye, yet challenging to detect in fast-paced environments. Cameras will be your best option when your specific application requires the examination of intricate designs, fine prints, and complex patterns.

Sensors, in contrast, are geared toward detecting physical defects, which can include inconsistencies in thickness, uneven surfaces, and alignment problems. Sensors are particularly useful when the problem relates to the substrate or alignment and is not clear visually. This is especially true when inspection control is centered around alignment precision, thickness, and flatness measures defined. In this regard, surface finish, and alignment disposition, sensors would be the best technology to employ.

2. Production Speed and Real-Time Feedback

Production line speed and the necessity for real-time feedback are interrelated. In rapid production environments where instantaneous defect detection and feedback provision is vital, sensor technologies excel. Defect-responsive sensors can swiftly assess and compare a range of physical attributes, and initiate real-time corrections, streamlining production, continuous printing, and other processes.

Camera systems can also operate at high speeds, however, the data processing requirements for high-resolution images can result in feedback being delayed. In data-heavy environments, cameras are a computational burden, and real-time defect detection is often achieved with sensors for operational applications requiring low feedback latency. As such, sensors are the preferred technology for rapid feedback systems.

3. Cost Considerations

The most important distinguishing technology for production printing is cost. Advanced features in camera systems, such as high-resolution imaging, multi-channel color detection, and automated calibration, have a high cost of ownership and operational expenditure. Installation and calibration demand further technical sophistication and cost which is significant. Such cameras may be integrated with specialized lenses and within automated control systems for lighting to ensure consistent high-resolution imaging, thus adding further complexity to the cost structure.

In contrast, sensors use simpler technologies compared to cameras, which reduces processing requirements and costs. Sensors can be integrated into almost any production line, and their installation typically does not require specialized expertise, making it ideal for cost-conscious companies and those needing basic automated inspection systems.

4. Environmental Sensitivity and Durability

Environmental conditions play an important role in deciding which kind of technology to use. For example, camera systems require specific lighting conditions to work well. Light and surface conditions must be constant and controlled to avoid reflections, gloss, or distortions that leave cameras blind to certain features. In fact, cameras require more maintenance and environmental control than sensors because they are more negatively impacted by dust, moisture, and other environmental features.

In contrast, sensor systems tend to be more robust against environmental factors. They remain unaffected to a certain extent by changes in illumination, while dust and moisture do not compromise their functionalities to a significant degree. This makes sensor systems, such as laser and ultrasonic sensors, a dependable choice for spotting defects in environments where illumination is variable and external factors are unpredictable.

5. Integration and Complexity

Incorporating camera or sensor technologies into your current systems can be done in numerous ways, and it is critical to understand how complicated each option is likely to be in terms of installation and future upkeep. For a camera system to function properly, significant attention must be given to alignment and calibration, and control of the ambient light, not to mention the intricate software designed for image processing and analysis. Furthermore, the integration of camera systems seems to take longer for training and support and requires a more sophisticated planning.

In contrast to camera systems, sensor systems are more easily incorporated into production lines and require far less technical know-how for installation and calibration. From the perspective of maintenance and operation, sensor systems offer business a straightforward approach in regard to reliable, minimal disruption inspection systems.

6. Data and Analysis Capabilities

The degree of analytical depth and type of data output is a pivotal factor. Cameras capture a multitude of detailed visual information and provide sufficient analysis for advanced defect classification and detection of fine range discriminations in print quality. The visual defect analysis conducted by a camera system allows for the inspection of intricate designs including minute graphical elements and text as well as the analysis of color consistency and the alignment of patterns.

In contrast, sensor systems offer quantitative data regarding the physical properties of the material, including thickness, alignment, and surface condition, yet they do not have a visual capability for print analysis. While sensors offer important quantitative data for quality analysis, they do not capture the depth of information necessary for complete quality assessments. Therefore, if a detailed analysis of print quality is essential for your application, camera systems are the appropriate option. Conversely, for rapid and basic defect detection in regard to physical properties, sensors will provide sufficient functionality.

7. Maintenance and Longevity

Another important consideration is the long-term durability of the 100% inspection systems. With fewer moving parts and no need for consideration of the ambient conditions such as light, sensor systems tend to be more durable. This makes such systems more convenient to long production runs at high volume. Moreover, the sensor systems are less likely to suffer from wear from external conditions, thereby reducing the interruptions in the production process and the associated costs for maintenance.

While camera systems are robust, they are more impacted by wear and ambient factors. The need for lighting, software, and precise optics increases the frequency of required maintenance due to the need to clean and calibrate the lenses and imaging sensors. Consequently, in situations where the system should require minimal maintenance, sensors are often the better option.

Summary

- Cameras technologies are the ideal solution for complex print inspection, facilitating the detailed, visual defect detection due to high-resolution images and sophisticated color discernment.

- For speed, cost-efficiency and the ability to withstand environmental factors, sensor technologies become more practical and effective.

- In many cases, the best solution involves the both use of camera and sensor technologies. This integrates the best of both technologies to deliver high-quality printed material.

Final Thoughts

Each of the camera and sensor technologies in 100% print inspection systems has its own distinct merits. Analyzing the unique advantages and disadvantages of each technology enables businesses to customize their printing inspection systems according to their production processes to achieve optimum quality and minimal defective outputs in the printed materials.