Automatic Adjustment and Feedback in Print Inspection

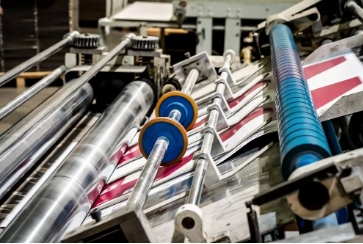

Printing industries today still have the challenge of ensuring the uniformity of the output quality while keeping the volume of high output. Defects can occur due to uneven ink distribution, problems with the substrate, and poor mechanical alignment. Automatic adjustment and feedback in print inspection have been an effective solution in the industry, allowing printers to identify problems in real time and self-correct during continued operation.

Table of Contents

Challenges in Human-Operated Print Inspection Systems

| Challenge | Description | Impact on Print Quality |

| Human Error | Manual inspection relies on human attention and judgment, which can vary between operators. | Missed defects or inconsistent quality control. |

| Fatigue and Attention Span | Long shifts and repetitive tasks reduce concentration. | Increased likelihood of oversight and errors. |

| Subjectivity | Different operators may have varying standards for defect identification. | Inconsistent defect detection and approval decisions. |

| Limited Speed | Humans cannot inspect high-speed production lines as fast as automated systems. | Slower throughput and potential backlog in production. |

| Difficulty in Detecting Minor Defects | Small color variations, misalignments, or subtle print flaws may go unnoticed. | Minor defects can accumulate, affecting overall product quality. |

| Training Requirements | New operators require significant training to reach proficiency. | High labor costs and variable inspection effectiveness. |

| Documentation and Data Analysis | Manual inspections rarely generate detailed digital records. | Limited ability to track trends, analyze defects, or improve processes. |

| Physical Strain | Continuous standing and repetitive motion can cause discomfort or injury. | Reduced operator efficiency and potential absenteeism. |

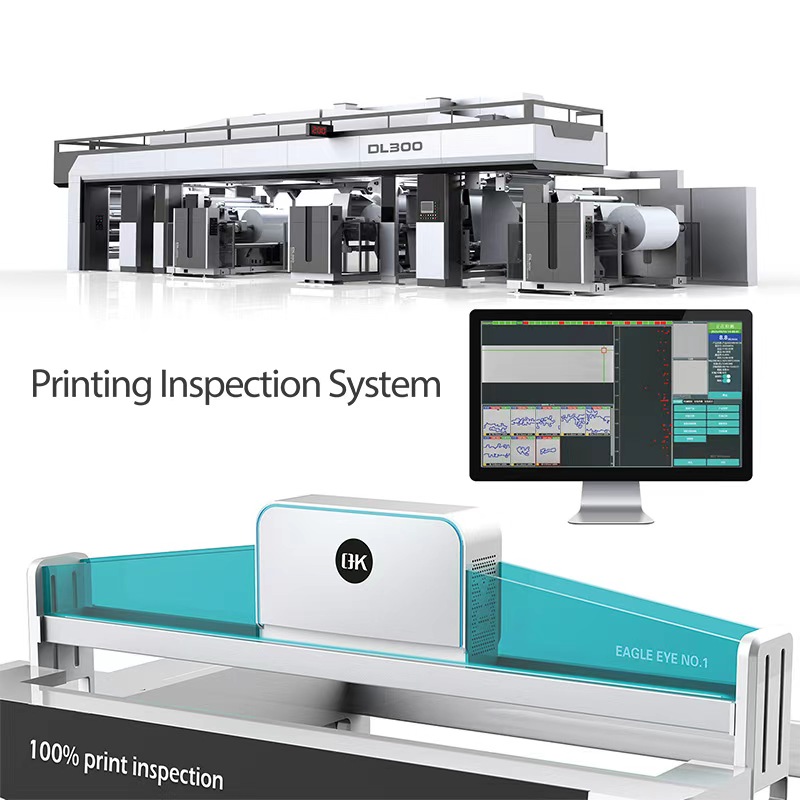

How Automatic Adjustment Works in Print Inspection Systems

It is important for operators, managers, and engineers to understand automatic adjustment in print inspection system to ensure the optimization of the production process and the reduction of defects.

Real-time Monitoring and Detection

Real-time monitoring is the initial part of the automatic adjustment process. Since high-resolution cameras and other advanced sensors have been designed to track materials in print production, it is these devices that monitor the color, alignment, ink coverage, and quality of other parameters. Continuous monitoring allows these systems to track even the slightest changes that can affect overall print quality.

Data Analysis and Defect Identification

After data collection, advanced algorithms get to work on analyzing images to see if there are any defects. Each printed output is evaluated against a set standard of quality and reference images. Through pattern recognition, color profiling, and machine learning, the system efficiently classifies defects, recognizes their level of severity, and determines the source of the defect in the printing workflow. This analysis is vital for recommending the necessary adjustments for issue resolution.

Key Components in Automatic Feedback Mechanisms for Print Inspection

1. High-Speed Vision Systems

High-speed vision systems are the core of automatic feedback systems. As the prints advance through the production line, the cameras and imaging sensors capture the materials in detail and continuously. Defect detection in color inconsistencies, misalignment, streaks, and absence of elements is largely dependent on the speed and resolution of the systems. Advanced vision systems form the very first step in the feedback loop and are able to monitor every sheet or segment of a roll without halting production.

2. Image Processing and Analysis Software

Once images are taken, the next step is figuring out what the images mean. This involves comparing the printed versions with the reference standards and spotting differences in color, registration, and graphics. Many modern 100% full-surface print inspection systems adopt automatic feedback mechanisms with AI and Machine Learning technologies to classify, evaluate, and find patterns in defects that may point out ongoing issues. This added analytics feature converts data captured in images into useful information needed by the printing equipment.

3. Control Units and Interfaces

The control unit is the main command center. It takes in information from the vision system and analysis software, then decides what corrections are needed. It connects to the printer control interfaces that regulate the flow of ink, printhead positioning, roller pressure, and positioning of the substrate. There must be a dependable link to the control unit so it can make real-time adjustments quickly and keep the production line moving.

4. Actuators and Mechanical Adjustment Components

After the correction is determined, actuators and control adjustment components makes the necessary changes to the printout by moving to the adjustment that was signaled. Verification and adjustments can be made using motorized rollers, printhead adjustment, tension control, or ink flow valves. With the feedback control system in place, these are the elements that provide the needed precision and immediacy to the corrections.

5. Data Logging and Reporting Systems

Data logging and reporting systems can be taken for granted. However, they perform the vital function of capturing information about the occurrence of defects, the adjustments taken, and the parameters of production over time. This information vital for operators looking to analyze trends to root causes and improvements to made over time to the printing process. This information captures trends and can be used for predictive maintenance. Such data will support improvements to maintenance as well as improvements to the product and the process.

6. Integration with Production Workflow

The final component is the integration with the overall production workflow. For automatic feedback systems to function optimally, they need to be part of a harmonized system involving the printer, inspection sensors, and control software. This can make sure the feedback jumps are leapfrogged to avoid production halts and can index to a continuous flow. This optimizes throughput and minimizes waste.

Benefits of Automatic Adjustment and Feedback in Printing Inspection

| Benefit | Description | Impact on Printing Operations |

| Improved Print Quality | Real-time monitoring and adjustments ensure consistent color, alignment, and clarity. | Reduces defects and maintains high-quality output across the production run. |

| Reduced Material Waste | Defects are corrected immediately, minimizing the amount of scrap paper or substrates. | Lowers operational costs and supports sustainability goals. |

| Increased Productivity | Automatic corrections reduce the need to stop production for manual inspection. | Maintains continuous workflow and higher throughput. |

| Consistency Across Runs | Continuous feedback ensures uniformity across different batches. | Enhances brand reliability and customer satisfaction. |

| Data-driven Process Optimization | Collected inspection data helps identify recurring issues and refine processes. | Supports predictive maintenance and long-term efficiency improvements. |

| Lower Labor Requirements | Reduces reliance on manual inspection and intervention. | Frees operators for other tasks, decreasing labor costs and fatigue. |

| Faster Issue Detection | Defects are detected immediately rather than after a full run. | Minimizes downtime and prevents defective products from reaching the market. |

| Enhanced Sustainability | Efficient use of materials and reduced waste contribute to greener production. | Supports corporate sustainability initiatives and reduces environmental impact. |

Future Outlook of Automatic Adjustment and Feedback in Print Inspection

The printing industry is evolving rapidly, driven by increasing demands for quality, efficiency, and sustainability. Automatic adjustment and feedback systems in print inspection will continue to improve the operational capabilities of the industry while paving the way for self-optimizing printing.

1. Integration with Artificial Intelligence

The future of print inspection includes the incorporation of artificial intelligence (AI) technology. AI systems will help printers detect and classify defects, even the most minor ones. To help avoid issues before they occur, machine learning will assess and analyze data from multiple production runs over a certain period and make necessary adjustments. This will help reduce machine actual run time, improve first-pass yield, and reduce the amount of material waste even more.

2. Smart Factory Connectivity

The prediction of 100% printing inspection systems will be integrated with machine print and smart inspection technology. This will be interconnected with the Internet of Things (IoT) integrated smart manufacturing eco-systems. Feedback from one machine can inform adjustments cross the prints, ensuring uniformity and efficiency. Real-time data sets will be available and can be used for continuous aligned decision-making.

3. Advanced Sensor Technologies

Sensors will continue to improve. This will include the ability to capture information with even greater precision, at finer and faster scanning intervals. Further development of sensors will incorporate meso-spectral imaging and even tridimensional scanning, to allow more sophisticated examination and printing. These will allow control of automatic adjustments for control without assuming a loss of quality.

4. Sustainability and Efficiency

Due to growing environmental concerns, industry changes will prioritize sustainability. Automatic adjustment and waste feedback systems will minimize waste by correcting defective materials on the fly, instead of wastefully discarding them. These systems will help greener and more responsible printing operations by optimizing ink use, minimizing energy use, and improving overall waste operational efficiencies.

5. Human-Machine Collaboration

Despite advances in automation, human expertise will still be needed. Enhanced human-machine collaboration systems will be able to quickly provide operators with actionable insights and guidance. This will enable rapid troubleshooting, rational decision-making, and the ability to continuously improve with flexibility for specialized printing requirements.

6. Continuous Learning and Adaptation

Next-generation feedback systems will be able to incorporate feedback to analyze operational patterns, automating the printing to the best parameters to accommodate changes to materials, inks, and environmental conditions. This self-learning will improve long-term performance, decrease the need for maintenance, and improve the reliability of print operations overall.

Final Thoughts

Automatic adjustment and feedback in printing inspection takes quality control to a whole new level. The combination of cutting-edge sensors, clever software, and quality machinery allows for real-time adjustments to be made during the process. This not only improves the quality of the final product but also improves the bottom line, cuts costs, and promotes eco-friendly print practices.